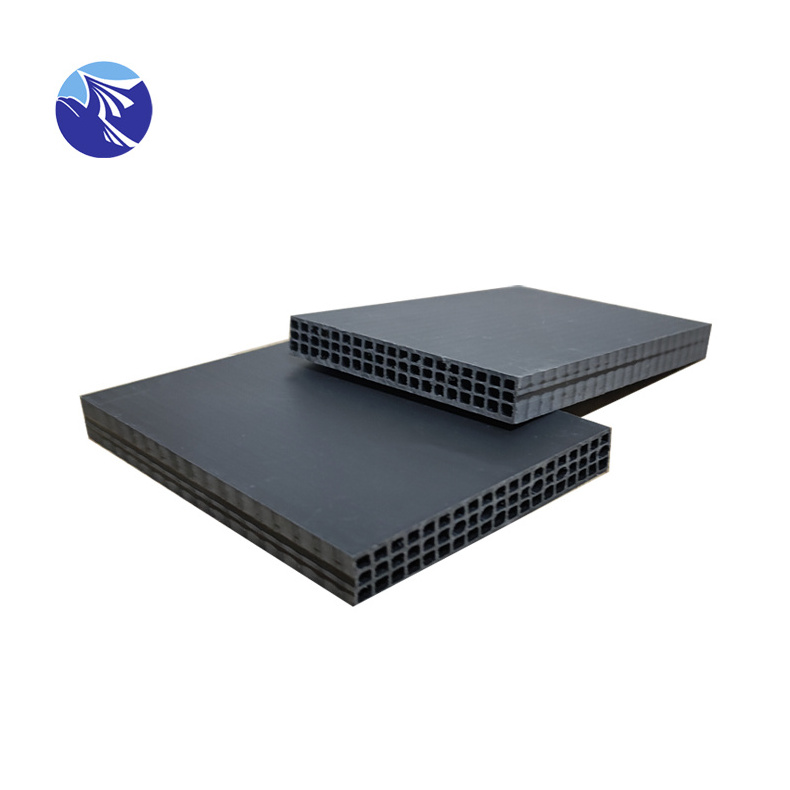

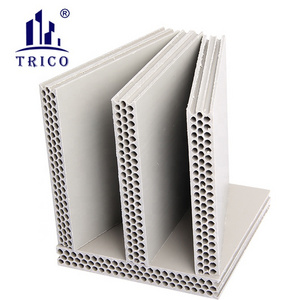

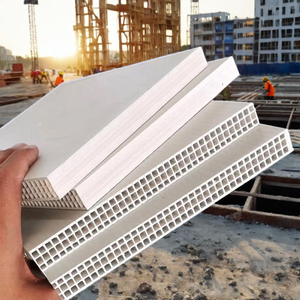

Recognize new polymer formwork reinforcement products: "new hollow plastic building formwork"

leading industry adopts imported polypropylene resin as the base materi al, innovates and increases the process of polymer alloy, through chemical molecular

structure reorganization, melting and extrusion molding, high temperature resis tance, no deformation, and further outstanding product advantages

- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Type:

-

plastic formwork

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Pengxiang Trading

-

Model Number:

-

Alloy black

-

Material:

-

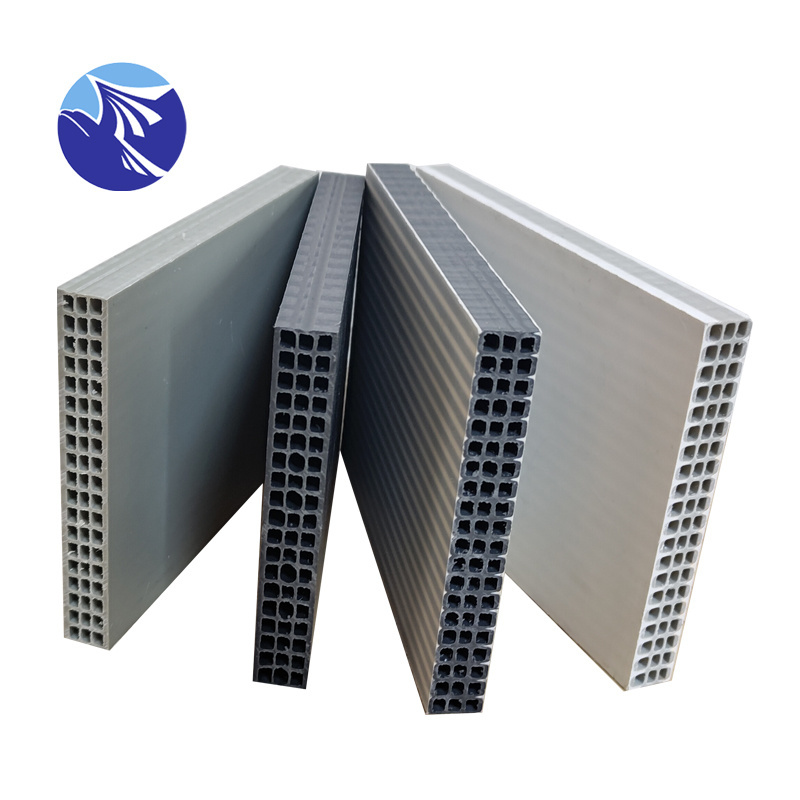

Plastic alloy modified material ;Polypropylene resin

-

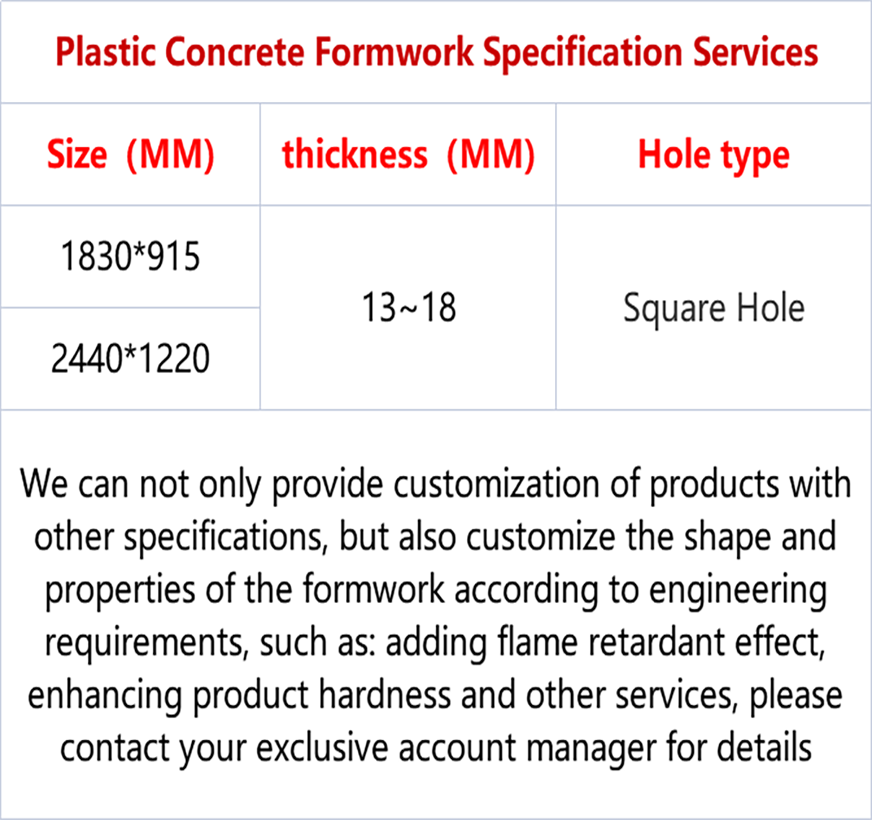

Product Size:

-

Custom sizes are supported

-

Color:

-

Black

-

Tensile Strength:

-

≥18.0Mpa

-

Charpy impact strength:

-

≥21.0KJ/m²

-

Bending strength:

-

≥31.0Mpa

-

Flexural modulus of elasticity:

-

≥1100 Mpa

-

Shrinkage rate (longitudinal):

-

≤0.8%

-

Retraction rate (transverse direction):

-

≤0.6%

-

Screw holding force (board surface):

-

≥1200N

Quick Details

-

Warranty:

-

2 years

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

total solution for projects

-

Application:

-

Construction

-

Design Style:

-

Industrial

-

Type:

-

plastic formwork

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Pengxiang Trading

-

Model Number:

-

Alloy black

-

Material:

-

Plastic alloy modified material ;Polypropylene resin

-

Product Size:

-

Custom sizes are supported

-

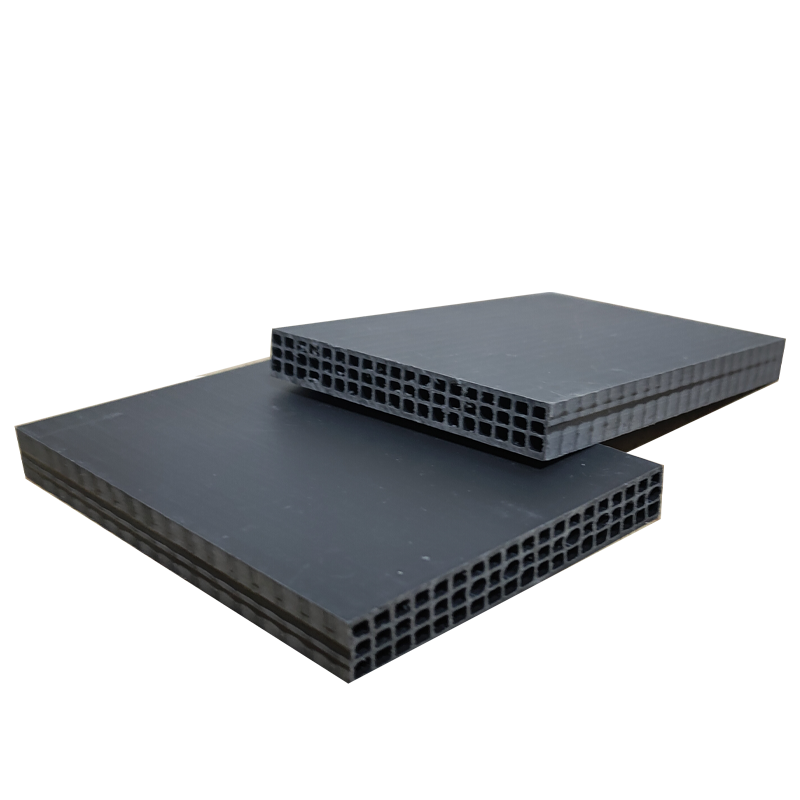

Color:

-

Black

-

Tensile Strength:

-

≥18.0Mpa

-

Charpy impact strength:

-

≥21.0KJ/m²

-

Bending strength:

-

≥31.0Mpa

-

Flexural modulus of elasticity:

-

≥1100 Mpa

-

Shrinkage rate (longitudinal):

-

≤0.8%

-

Retraction rate (transverse direction):

-

≤0.6%

-

Screw holding force (board surface):

-

≥1200N

Products Description

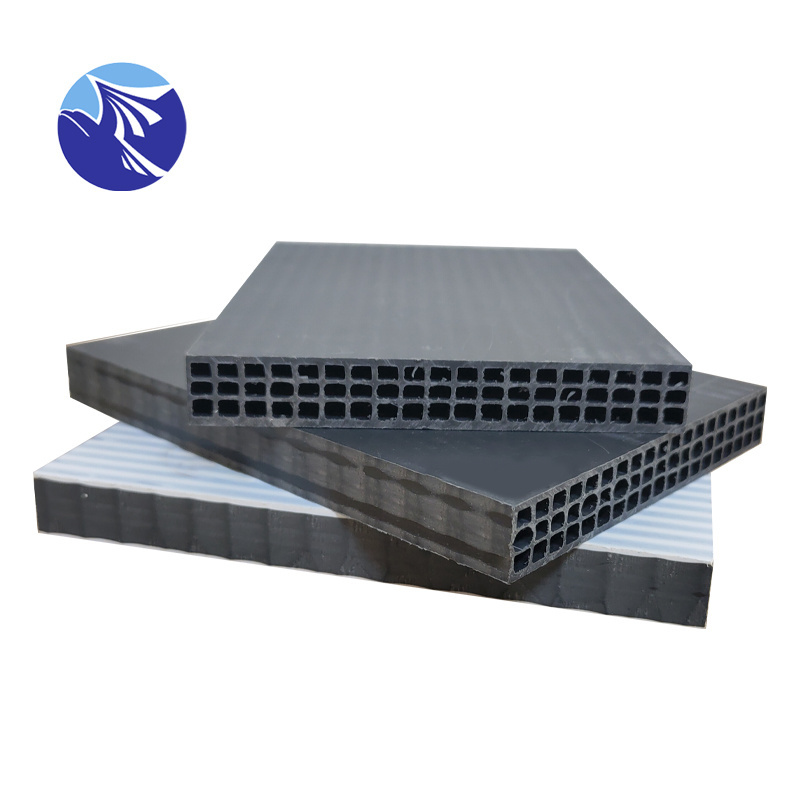

New hollow plastic building formwork

As a new product to replace the traditional wood formwork,Hollow plastic building formwork subverts and replaces tradition

Wood formwork and bamboo plywood have become an inevitable trend. here it is There is no environmental pollution during production and use, no toxic and harmful gas emissions, no construction waste during construction and use, and 100% recycling, which is convenient for site safety and civilization Construction management, not just cost savings, can apply for a green building award.

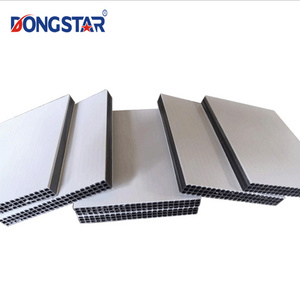

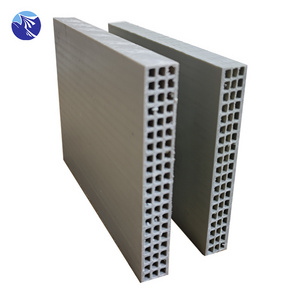

Can be used 50-100 times Green environmental protection, no pollution Recyclable

Light weight 、 high strength

Good hardness 、 impact resistance

Good hardness 、 impact resistance

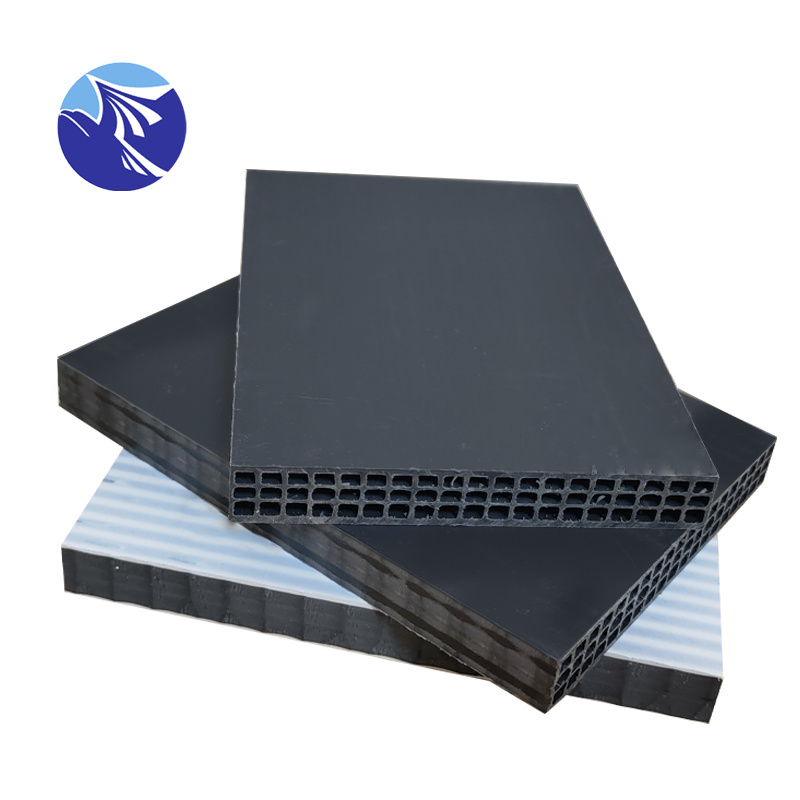

Long term immersion in water No deformation, delamination and blistering Non swelling, corrosion resistance, high and low temperature resistance

Easy weight, easy operation and quick construction

Waterproof, corrosion resistant, easy to handle, shorten working hours and save manpower

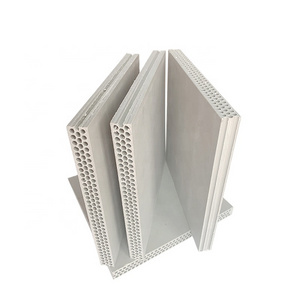

One time forming is smooth, high quality and low cost

Product technical certification

technical standard

Deep contrast analysis

Precautions for using plastic building formwork

Using a 15mm thick plastic building formwork, the wood square spacing is adjusted according to the thickness of the floor concrete and the thickness and height of the wall. There is no gap between the shear wall and the column mold panel, and the shade corner (bottom of the wall) must have a wooden square to facilitate the connection of beams, walls and formwork. When nailing nails in plastic formwork, it must be 1530mm from the edge, appropriate strength, and the length of the nail should be 4050mm. The beam floor must leave a 1.5 cm stop to save the wall panel material and not leak slurry.

Hot Searches