- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

packaging

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Rival Tech BOPET film

-

Model Number:

-

BOPET film

-

Product name:

-

BOPET film

-

Length:

-

As your request

-

Thickness:

-

Customized

-

Color:

-

Customized

-

Packaging:

-

Pallet

-

Features:

-

Blowing Plastic Film

-

Sample:

-

Free stock samples offered

-

MOQ:

-

1roll High density polyester based clear BOPET film

Quick Details

-

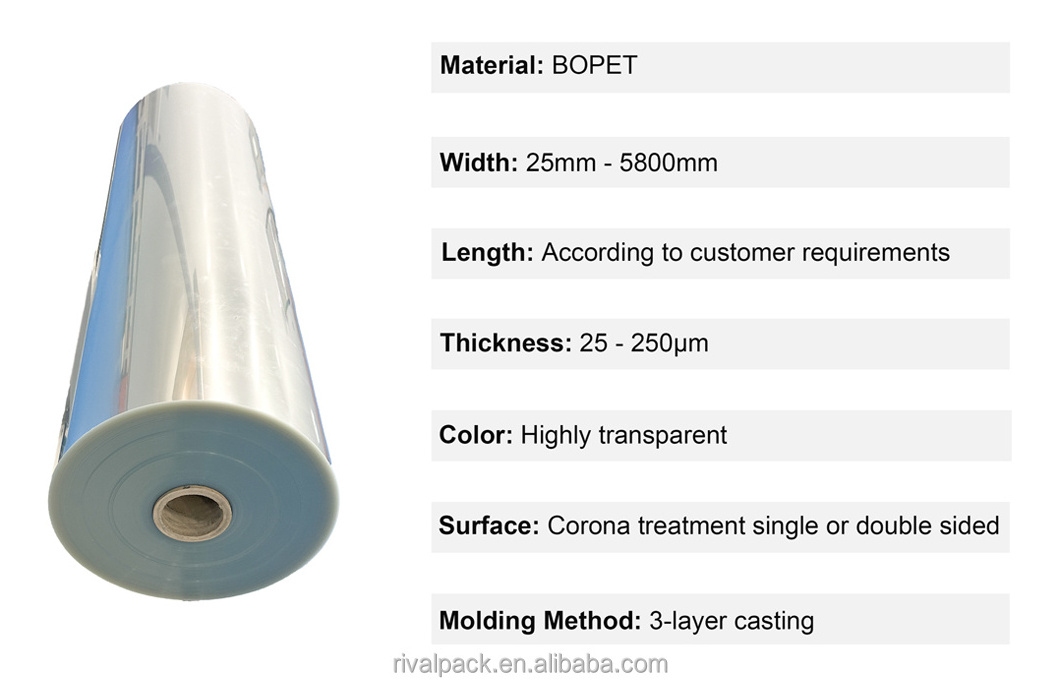

Material:

-

PE

-

Type:

-

Packing Film

-

Usage:

-

Packaging Film

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

packaging

-

Place of Origin:

-

Beijing, China

-

Brand Name:

-

Rival Tech BOPET film

-

Model Number:

-

BOPET film

-

Product name:

-

BOPET film

-

Length:

-

As your request

-

Thickness:

-

Customized

-

Color:

-

Customized

-

Packaging:

-

Pallet

-

Features:

-

Blowing Plastic Film

-

Sample:

-

Free stock samples offered

-

MOQ:

-

1roll High density polyester based clear BOPET film

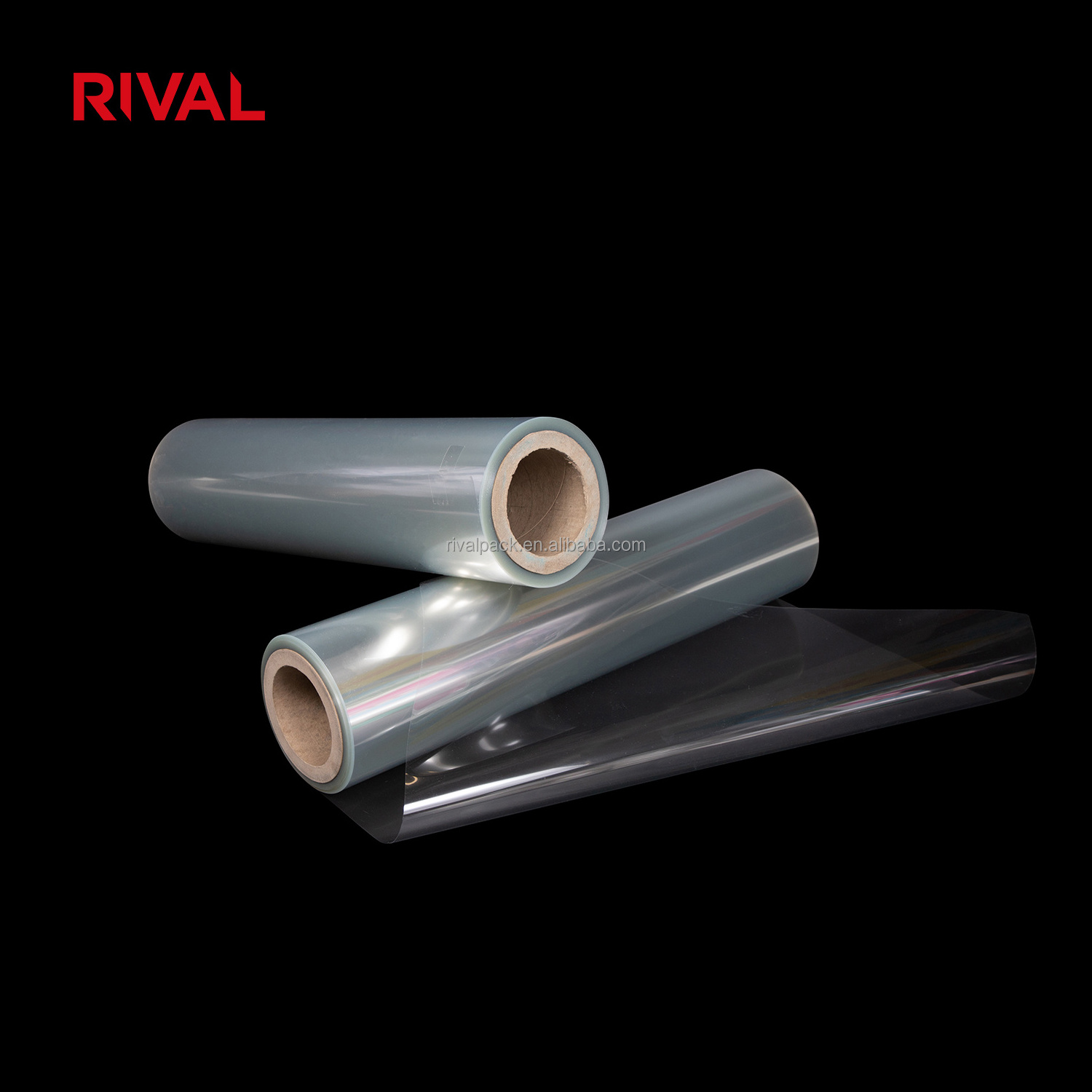

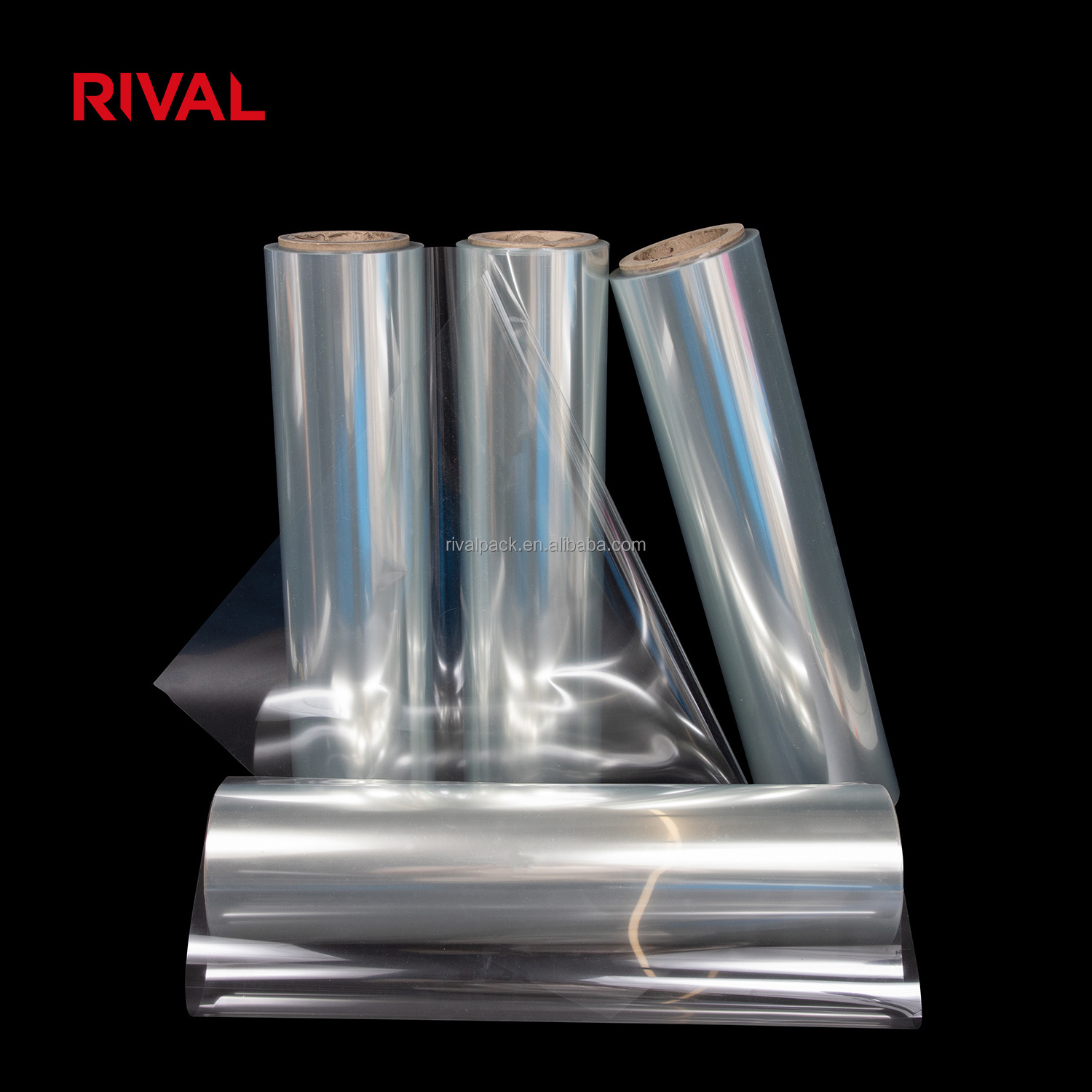

High quality bopet transparent film for FRP sheet bopet film rolls

What are BOPET Films?

BOPET (biaxially-oriented polyethylene terephthalate) is a polyester film made by stretching polyethylene terephthalate (PET) in its two primary directions to make a versatile engineered film that has amongst its many benefits high tensile strength, chemical and dimensional stability, transparency, reflectivity, gas and aroma barrier properties, and electrical insulation.

BOPET films have enabled many facets of our modern life by providing critical functionality to end markets such as consumer electronics, automotive, green energy and medical devices to name but a few. However, by far the largest use of BOPET film is in flexible packaging structures where the unique set of properties have enabled it to become the backbone that high performance MLP (multi layer plastic) structures are built around. BOPET films are incredibly resource efficient and punch above their weight in the flexible packaging market, and although BOPET films only count for between 5-10% of the overall volume by weight, the percentage of packaging structures that rely on BOPET films’ unique set of properties is a far higher percentage with up to 25% of packs using BOPET as a critical component.

|

Name

|

BOPET Film

|

|||

|

Tensile-Strength(lengthwise,crosswise),MPa

|

≥52.0

|

|||

|

Impact strength(cut)(four-way)KJ/M2

|

≥5.0

|

|||

|

Drop impact strenght

|

No fracture

|

|||

|

Vicat softening piont,°C

Decoration plate Industrial plate |

≥80.0 |

|||

|

Heating size change rate, %

Lengthwise Crosswise |

-5.0--+5.0 -3.0--+3.0 |

|||

|

Width

Length Diagonal line |

Deviation 0-3mm

Deviation 0-8mm |

|||

|

Advantage

|

This film has excellent clarity, good stiffness, smooth surface, good chemical and abrasion resistance. BOPET films are preferred for its easy processing and to achieve good oxygen barrier.

|

|||

|

|

Unit | Test Method | Test Position | Result | |

| Min. | Max. | ||||

| Nominal Thickness | Mircon | RIVAL - Method | Overall | 74 | 78 |

| Tensile Strength | Kg/cm2 | ASTM D-882 | MD | 1600 | 1700 |

| TD | 1450 | 1500 | |||

| Elongation | % | ASTM D- 882 | MD | 126 | 159 |

| TD | 111 | 132 | |||

| Coefficient of Friction | - | ASTM D- 1894 | STATIC | 0.36 | 0.42 |

| DYNAMIC | 0.26 | 0.34 | |||

| Gloss | % | ASTM D-2457 | Overall | 126 | 127 |

| Light Transmission | % | ASTM D-1003 | Overall | 89.1 | 89. 9 |

| Dart Impact Test | gram | ASTM D-1709 | Overall | 720 | Pass |

| Haze | % | ASTM D-1003 | Overall | 2.3 | 2.34 |

| Shrinkage @150 ºC /30' | % | ASTM D-1204 | MD | 1.0 | 1.2 |

| TD | -0.0 | -0.2 | |||

| Surface Tension | Dyne/cm | ASTM D-2578 | Both Side | 56 - 58 | |

It is versatile and can meet the needs of a variety of products. Our products are designed to make your life easier and more convenient.

Rival Quality Control Department focuses on every production process quality control and recording so that there will be no defects in the delivery of each order. Sampling is conducted every 3 hours from production beginning, middle and end to make sure 100% meet customer requirements.

Rival Tech Group has accumulated a wealth of production and innovation experience since 1983. Advanced 5-layers co-extruded blown film line from Europe with globally leading technology, large-scale production factories, complete QC test process, and Intelligent color matching system, supply excellent and environmental flexible packaging products to the world.

FAQ:

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer over 40 years experience, if you have interests welcome to visit our factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days after receiving your initial payment.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge by freight collect

Q: How do you ship the samples ?

A: Samples Shipping: Via International Courier (DHL, Fedex, UPS, TNT or Aramex etc...)

Q: What is your terms of payment ?

A: 40% T/T in advance ,balance before shippment. we slao accept L/C at Sight .

Q: What is your standard package ?

A: Common package: PE bag+ Kraft paper and PE wrapping + protection corner + Wooden Pallets.

Packaging size: 3'x6' or 4'x8' or according to customer's requirements.