1. High Compression Efficiency.

2. Compression of High-Purity Gases.

3. Lower Maintenance Rate.

4. Well-Performing Oil Pump System.

5. Diaphragm and Oil Pressure Alarms.

6. Enhanced Exterior Aesthetics.

7. Favorable Cooling Conditions for the Compressor.

8. Compact and Reasonably Designed Overall Structure.

- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Working Pressure:

-

0.1-5.0mpa

-

Gas Type:

-

Hydrogen

-

Product name:

-

Diaphragm hydrogen compressor

-

Application Range:

-

Hydrogen Refueling Main Station

-

Compressed Medium:

-

High-Purity Hydrogen Gas

-

Number of Compression Stages:

-

Two-stage or Three-stage

-

Inlet Pressure (Mpa):

-

1.5~2.2

-

Maximum Discharge Pressure (MPa):

-

22MPa

-

Design Flow Rate (Nm3/h):

-

≥1000 (Inlet 2MPa, Outlet 20MPa)

-

Total Power (KW):

-

160

-

Installation Method:

-

Skid-mounted

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

WOBO

-

Voltage:

-

220V/380V/415V(customizable)

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

Customized

-

Working Pressure:

-

0.1-5.0mpa

-

Gas Type:

-

Hydrogen

-

Product name:

-

Diaphragm hydrogen compressor

-

Application Range:

-

Hydrogen Refueling Main Station

-

Compressed Medium:

-

High-Purity Hydrogen Gas

-

Number of Compression Stages:

-

Two-stage or Three-stage

-

Inlet Pressure (Mpa):

-

1.5~2.2

-

Maximum Discharge Pressure (MPa):

-

22MPa

-

Design Flow Rate (Nm3/h):

-

≥1000 (Inlet 2MPa, Outlet 20MPa)

-

Total Power (KW):

-

160

-

Installation Method:

-

Skid-mounted

100% OIL FREE ZERO LEAKAGE HYDROGEN DIAPHRAGM COMPRESSOR

Latest Design Air Diaphragm Compressor 22Mpa Oil Free Hydrogen Diaphragm Compressor For Calibration

Product Description

The hydrogen diaphragm compressor booster

is a special structure of the volume-type compressor with high compression ratio, good leak tightness, compressed gas without lubricating oil and other solid impurities contaminated features.

WOBO diaphragm compressors consist of four types that are Z type, V type, L type and D type. The exhaust pressure ranges from 1.3 to 49Mpa. The products are widely used in the industries of national defense,

scientificresearch, petrochemical, nuclear power, parmaceutical, food-stuff and gas separation.

Oil-free 100% purity Hydrogen Diaphragm Compressor Structure

Product Parameters

|

Compressor Model

|

CMP-22(1.5-2.2)H2

|

CMP-45(1.5-2.2)H2

|

CMP-22(1.8-2.2)H2

|

|||

|

Dimensions (mm)

|

6500x2800x2500

|

4500x2800x2500

|

4500x2800x2500

|

|||

|

Application Range

|

Hydrogen Refueling Main Station

|

Hydrogen Production and Refueling Integrated Station

|

Hydrogen Refueling Main Station

|

|||

|

Compressed Medium

|

High-Purity Hydrogen Gas

|

High-Purity Hydrogen Gas

|

High-Purity Hydrogen Gas

|

|||

|

Explosion Protection Level

|

Ex de mb px II CT4

|

Ex de mb px II CT4

|

Ex de mb px II CT4

|

|||

|

Number of Compression Stages

|

Two-stage or Three-stage

|

Three-stage

|

Two-stage

|

|||

|

Number of Compression Systems

|

Dual System

|

Dual System

|

Single System

|

|||

|

Inlet Pressure (Mpa)

|

1.5~2.2

|

1.5~2.2

|

1.8~2.2

|

|||

|

Inlet Temperature (℃)

|

<45

|

<45

|

<45

|

|||

|

Maximum Discharge Pressure (MPa)

|

22MPa

|

45

|

22

|

|||

|

Discharge Temperature (after cooling) (℃)

|

≤35

|

≤35

|

≤35

|

|||

|

Design Flow Rate (Nm3/h)

|

≥1000 (Inlet 2MPa, Outlet 20MPa)

|

≥500 (Inlet 1.6MPa, Outlet 45MPa)

|

≥1000 (Inlet 2.0MPa, Outlet 20MPa)

|

|||

|

Main Motor Power (KW)

|

75x2

|

110

|

132

|

|||

|

Total Power (KW)

|

160

|

120

|

142

|

|||

|

Installation Method

|

Skid-mounted

|

Skid-mounted

|

Skid-mounted

|

|||

|

For more information, please contact us.

|

|

|

|

|||

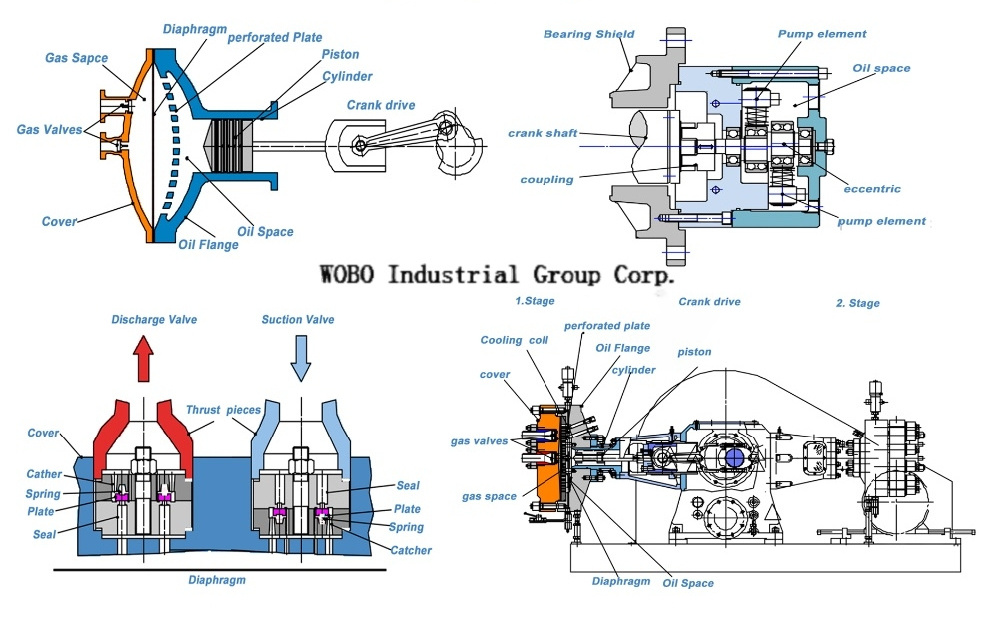

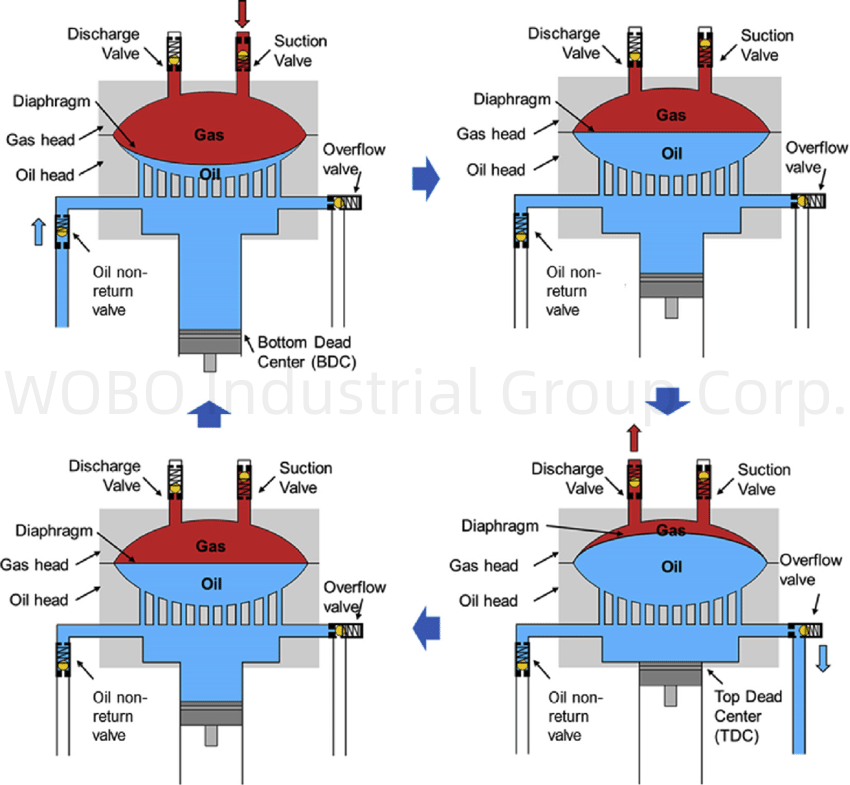

Technical Principle

Diaphragm compressor. A diaphragm compressor is a variant of the classic reciprocating compressor with backup and piston rings and rod seal. The compression of gas occurs by means of a flexible membrane, instead of an intake element. The back and forth moving membrane is driven by a rod and a crankshaft mechanism.

Structure and Working Cycle of Diaphragm Compressor

Product Advantages

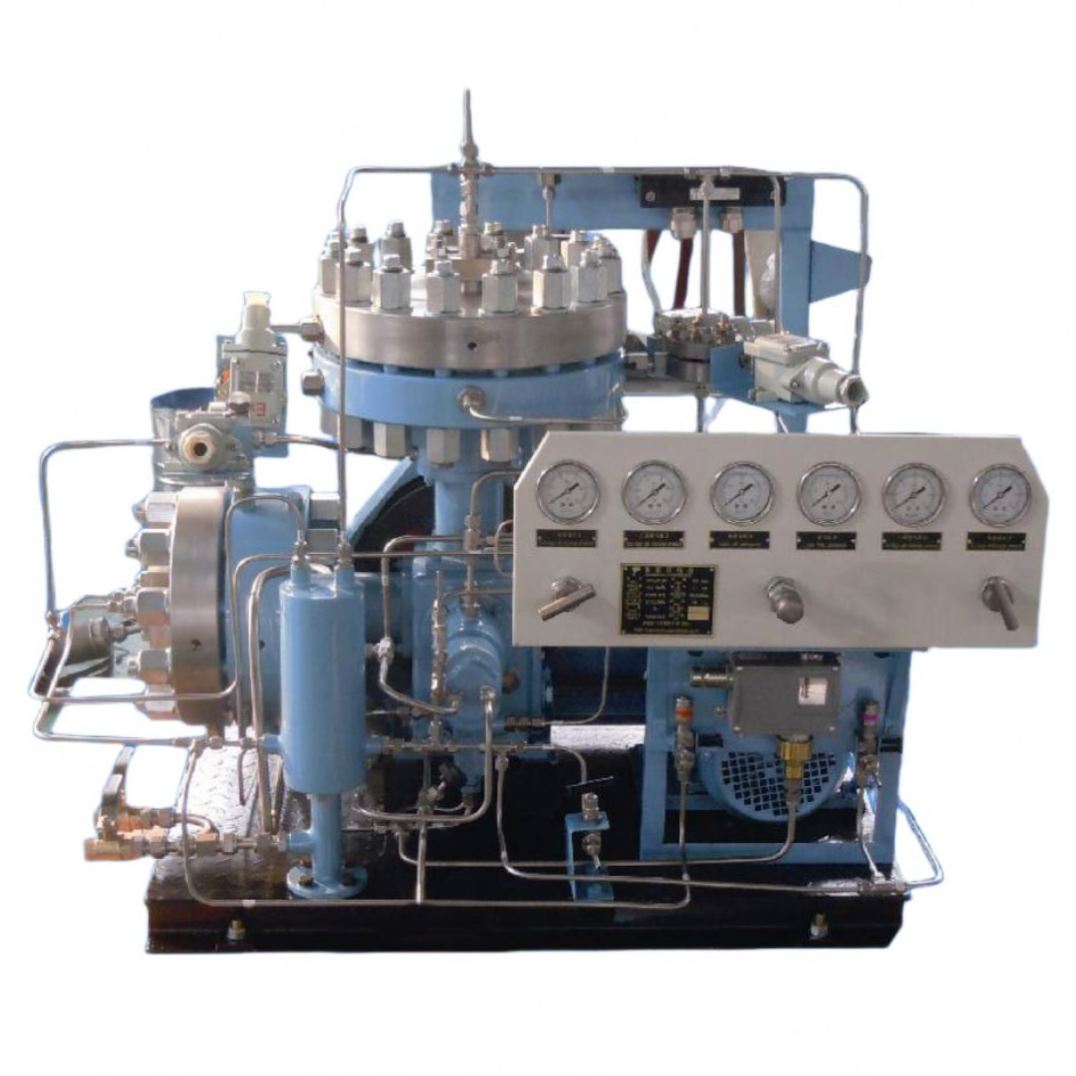

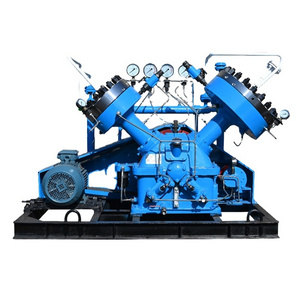

WD Type

Diaphragm

Compressor

WL Type Diaphragm Compressor

1. The overall equipment design is well-thought-out, ensuring smooth and reliable operation, minimal vibration, low noise, and facilitating practical operational maintenance.

2. The cylinder head components utilize a structure without mating oil plates, reducing the complexity of machining processes.

3. The adoption of a new thin-film chamber significantly enhances the diaphragm's lifespan.

4. Various pipeline designs of the machinery are effective, well-arranged, and visually appealing.

2. The cylinder head components utilize a structure without mating oil plates, reducing the complexity of machining processes.

3. The adoption of a new thin-film chamber significantly enhances the diaphragm's lifespan.

4. Various pipeline designs of the machinery are effective, well-arranged, and visually appealing.

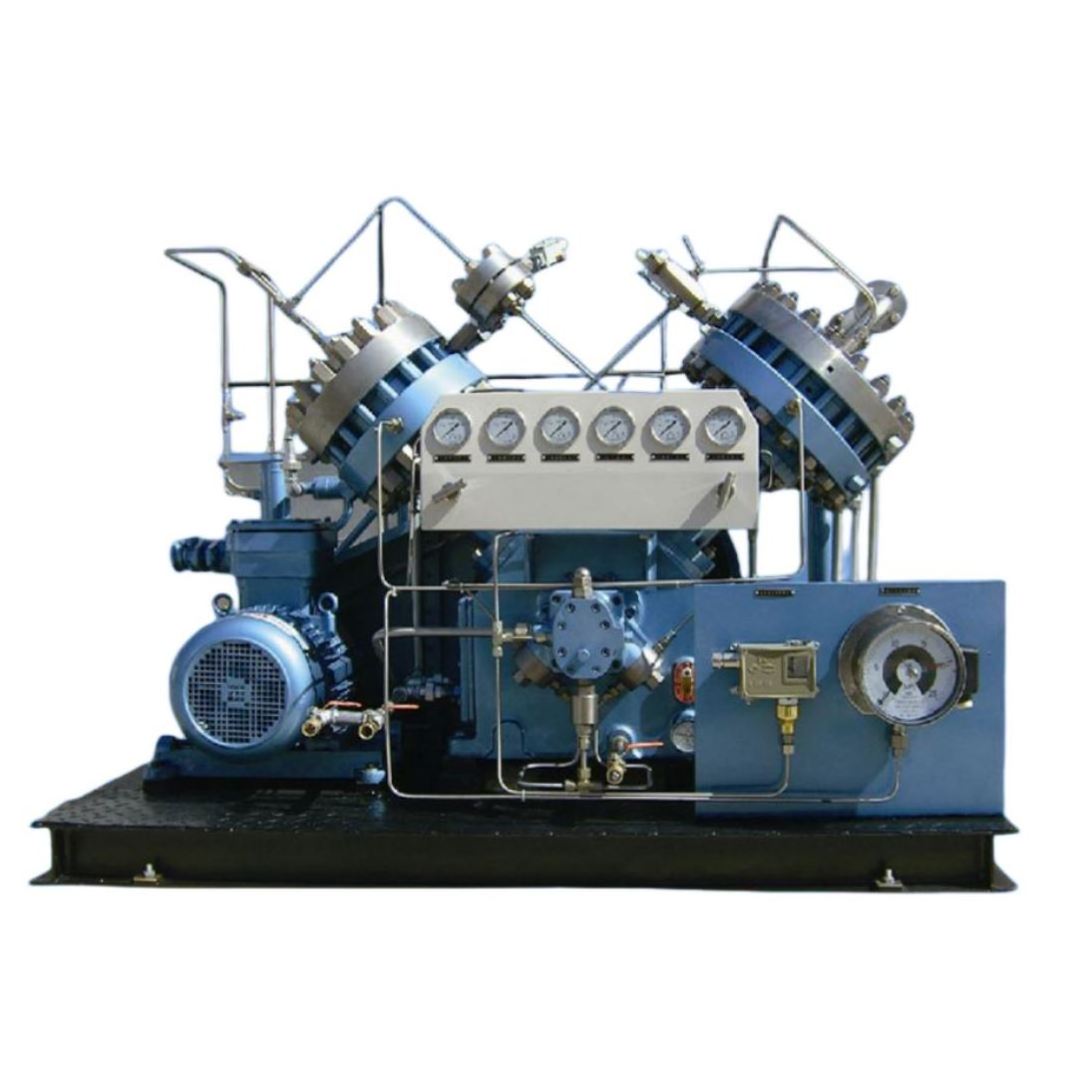

WV Type Diaphragm Compressor

1. The overall design of the machine is well-conceived, ensuring stable and reliable operation, minimal vibration, low noise, and ease of use and maintenance.

2. The cylinder body components adopt a structure without mating oil pans, reducing assembly complexities and minimizing sealing surfaces.

3. Alarm systems are in place to indicate compression medium leaks, enhancing the overall reliability of the machine.

4. An integrated oil pump station addresses the issue of oil leakage that was present in externally-mounted compressors.

5. High level of automation ensures the equipment's safe operation.

6. The entire equipment is consolidated onto a single skid base, facilitating transportation, installation, and management of the equipment.

2. The cylinder body components adopt a structure without mating oil pans, reducing assembly complexities and minimizing sealing surfaces.

3. Alarm systems are in place to indicate compression medium leaks, enhancing the overall reliability of the machine.

4. An integrated oil pump station addresses the issue of oil leakage that was present in externally-mounted compressors.

5. High level of automation ensures the equipment's safe operation.

6. The entire equipment is consolidated onto a single skid base, facilitating transportation, installation, and management of the equipment.

WZ Type Diaphragm Compressor

1. Compression of High-Purity Gases.

2. Lower Maintenance Rate.

3. Well-Performing Oil Pump System.

4. Diaphragm and Oil Pressure Alarms.

5. Favorable Cooling Conditions for the Compressor.

6. Compact and Reasonably Designed Overall Structure.

2. Lower Maintenance Rate.

3. Well-Performing Oil Pump System.

4. Diaphragm and Oil Pressure Alarms.

5. Favorable Cooling Conditions for the Compressor.

6. Compact and Reasonably Designed Overall Structure.

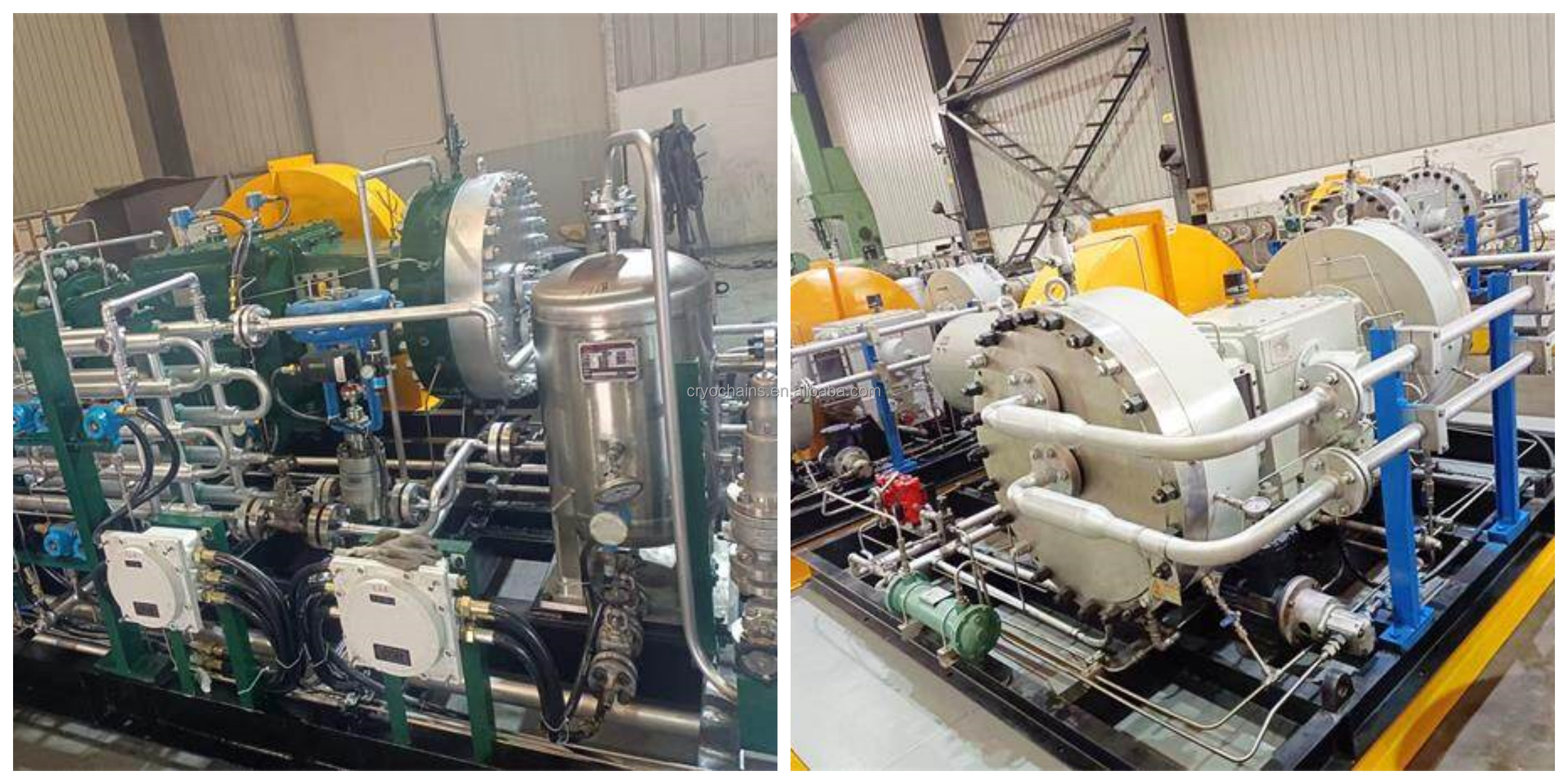

Product Application

Project Case

Certifications

Hot Searches