Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

China

-

Brand Name:

-

Forest Paint

-

Model Number:

-

FP-CP5231

-

Product Name:

-

Car paint

-

Material:

-

Acrylic

-

Color:

-

Blue,purple,red,yellow,green etc.

-

Feature:

-

High gloss,bright color,good Covering Power,High Solid

-

Packing:

-

0.5L&1L&2L&4L&5L, etc.

-

Spray coats:

-

2-3 coats(40-60um)

-

Substrate:

-

Sanded and dried existing finish

-

Keywords:

-

Fluorescent car paint

Quick Details

-

CAS No.:

-

9063-87-0

-

Other Names:

-

Automotive paint

-

MF:

-

Mixture

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

China

-

Brand Name:

-

Forest Paint

-

Model Number:

-

FP-CP5231

-

Product Name:

-

Car paint

-

Material:

-

Acrylic

-

Color:

-

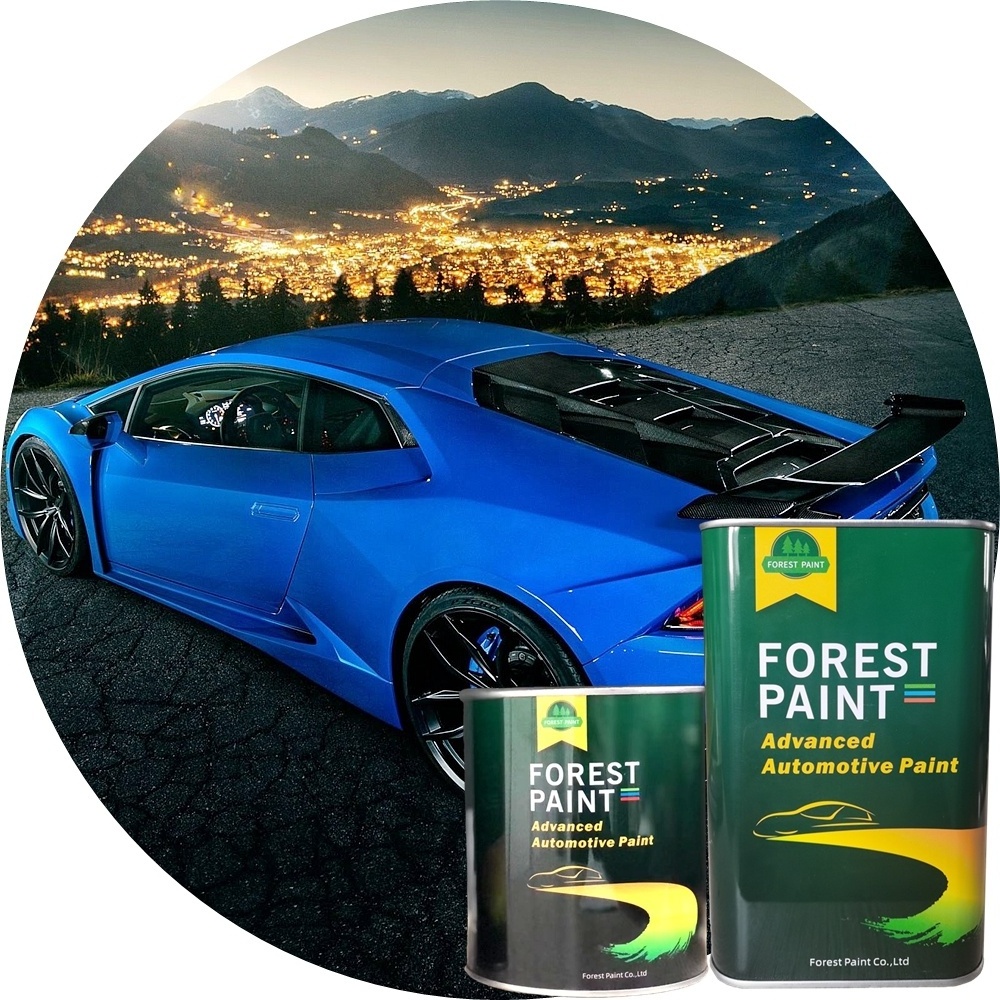

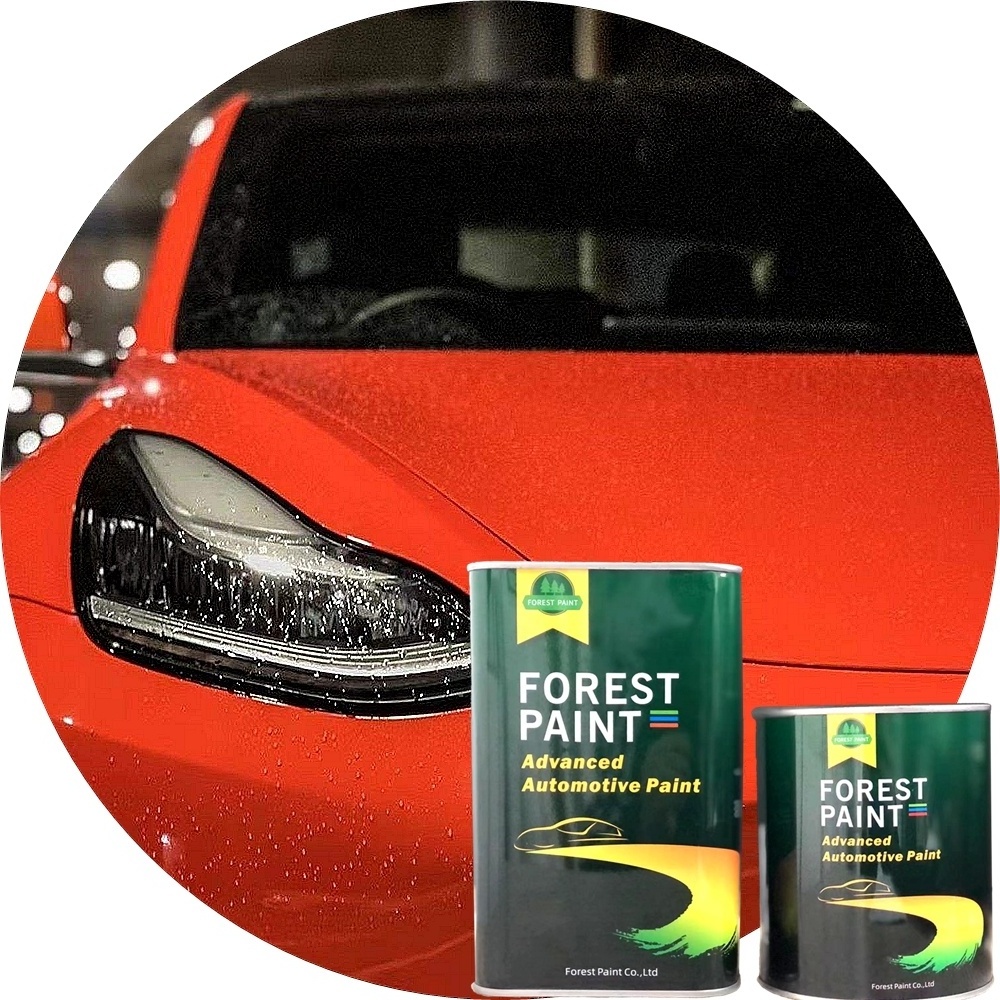

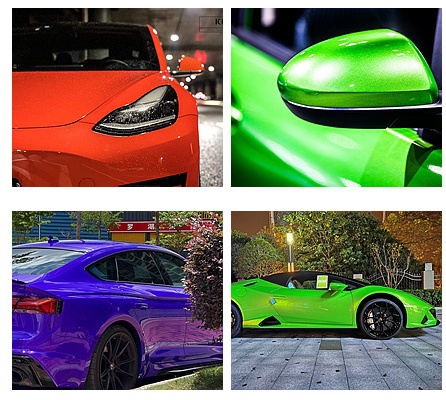

Blue,purple,red,yellow,green etc.

-

Feature:

-

High gloss,bright color,good Covering Power,High Solid

-

Packing:

-

0.5L&1L&2L&4L&5L, etc.

-

Spray coats:

-

2-3 coats(40-60um)

-

Substrate:

-

Sanded and dried existing finish

-

Keywords:

-

Fluorescent car paint

Products Description

FOREST Good Quality Car Paint Fluorescent Blue Purple

Auto Car Coating Paint for Car Body

Fluorescent car paint is a two-component product consisting of a main paint containing hydroxyl acrylic resin, pigments, additives, solvents, and a curing agent containing aromatic diisocyanate prepolymer. The color is bright and bright.

1. Bright and beautiful color,

2. Fast drying paint film,

3. Good hardness and

strong adhesion,

4. Good color retention, full paint film,

5. Good chemical resistance.

Application

Fluorescent car paint

is a very bright and quick-drying enamel paint, which belongs to acrylic resin paint. The brightness can reach about three times that of ordinary paints, which is unmatched by other paints. At the same time, the colors are particularly bright and the color purity is high.

How to use

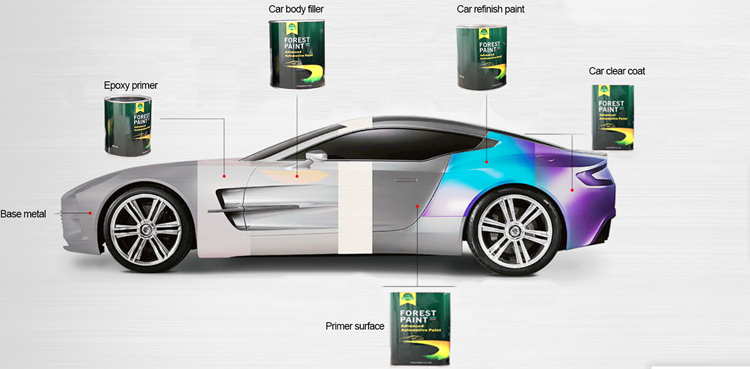

Product construction:

1. Substrate treatment:

The surface of the workpiece should be rust-removed and oil-removed, and ensure that it is clean, dry and free of dirt. The dust should be removed and filled before the primer can be sprayed.

2. Primer spraying:

Two-component mixing ratio:

white primer: primer curing agent: thinner = 4: 1: appropriate amount

One-component mixing ratio:

white primer: thinner = 1: 0.8

Construction method:

air spraying, spray gun aperture: 1.8~2.5mm, spraying pressure: 3~4kg/cm2

Mixing use time:

The two-component paint is used up within 2 hours after adding the curing agent.

When the ambient temperature is higher than 30 °C, the use time after mixing should be shortened.

Compatible Coating:

Apply directly on the metal surface that has been surface-treated.

3. Topcoat spraying:

Two-component mixing ratio:

fluorescent paint: topcoat curing agent: thinner = 4:1: appropriate amount

Single-component mixing ratio:

stir evenly and spray directly.

Construction method:

air spraying, spray gun aperture: 1.8~2.5mm, spraying pressure: 3~4kg/cm2

Mixing use time:

The two-component paint is used up within 2 hours after adding the curing agent.

When the ambient temperature is higher than 30 °C, the use time after mixing should be shortened.

Matching coating:

15-20 minutes after the primer is sprayed, the topcoat is sprayed.

4. Matters needing attention:

The construction temperature is above 5℃, the construction humidity is not more than 85%, and the surface temperature of the substrate should be above 3 degrees above the dew point;

Before construction, the air compressor and filter should be dehydrated to avoid needles caused by the paint film Holes;

The product must be fully stirred before use;

The remaining curing agent after use should be sealed in time to prevent moisture absorption and deterioration.

5. Safety and environmental protection regulations:

This product contains flammable organic solvents. It should be used in accordance with the safety regulations and process operation specifications for painting operations.

The construction site should be kept away from fire sources, ventilation, and protective measures such as fire prevention, anti-static, and anti-poisoning.

Hot Searches