- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DahoMeter

-

Model Number:

-

DHL-120

-

Usage:

-

Salt Spray Testing Chamber

-

Power supply:

-

AC220V 50HZ 20A

-

Temperature accuracy:

-

±1°C

-

Volume:

-

600L

-

Interior dimensions(mm)L*W*H:

-

1200*1000*600

-

Exterior dimensions(mm)L*W*H:

-

1950*1250*1400

-

Test method:

-

NSS, CASS, AASS

-

Certificate:

-

ASTM, JIS, ISO

Quick Details

-

Warranty:

-

1 Year

-

Power:

-

Electronic

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

DahoMeter

-

Model Number:

-

DHL-120

-

Usage:

-

Salt Spray Testing Chamber

-

Power supply:

-

AC220V 50HZ 20A

-

Temperature accuracy:

-

±1°C

-

Volume:

-

600L

-

Interior dimensions(mm)L*W*H:

-

1200*1000*600

-

Exterior dimensions(mm)L*W*H:

-

1950*1250*1400

-

Test method:

-

NSS, CASS, AASS

-

Certificate:

-

ASTM, JIS, ISO

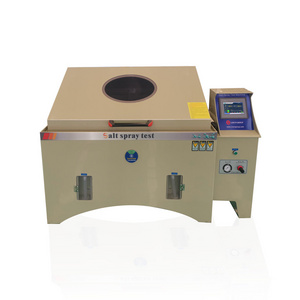

DHL-120 ASTM/ISO Touch-screen Environmental Test Chamber Salt Spray Testing Chamber/Salt Spray Testing Machine

Products Description

Features

The salt spray test chamber uses salt spray corrosion method to detect the reliability of the corrosion resistance for the test samples. Salt fog refers to the dispersion system composed of tiny droplets of salt in the atmosphere. It is one of the instruments for three kinds of artificial environmental protection (moist heat,salt mist,bacteria). Many companies need to test out the destructive effect on the products by simulate marine climate,that's why comes out the salt spray testing chamber. The machine can be classified as neutral salt and acid salt. The difference is based on the testing standards and testing methods, which is respectively called "NSS" and "CASS" testing.

This product meets the standards of CNS、ASTM、JIS、 ISO ,etc. The salt spray test is to test the corrosion resistance of the surface of various materials after coating, electroplating, anodizing, anti-rust oil and other anti-corrosion treatment.

Standards

CNS3627, 3885, 4159, 7669, 8886, JISD-0201, H-8502, H-8610, K-5400, Z-2371, ISO 3768, 3769, 3770, ASTMB-117, B-268, GB-T2423, GJB 150.

Material

1. 5MM imported gray and white impact resistant PVC board which has high temperature resistance up to 85°C, corrosion resistance.

2. Support shelf is φ10MM glass fiber rod, which has corrosion resistance. Plastic-steel V-shaped brackets and fiber rods is placed at an angle to ensure that the test object is inclined at 15-30 degrees.

3. Pressure bucket adopts seamless welding by 2.0MM SUS304 stainless steel plate.

4. Using titanium alloy heating tube for heat generation, long service life and high corrosion resistance.

5. The cover is made up of 5MM imported transparent (YLIS from German) acrylic board which has fine workmanship, beautiful appearance and high transparency.

The salt spray test chamber uses salt spray corrosion method to detect the reliability of the corrosion resistance for the test samples. Salt fog refers to the dispersion system composed of tiny droplets of salt in the atmosphere. It is one of the instruments for three kinds of artificial environmental protection (moist heat,salt mist,bacteria). Many companies need to test out the destructive effect on the products by simulate marine climate,that's why comes out the salt spray testing chamber. The machine can be classified as neutral salt and acid salt. The difference is based on the testing standards and testing methods, which is respectively called "NSS" and "CASS" testing.

This product meets the standards of CNS、ASTM、JIS、 ISO ,etc. The salt spray test is to test the corrosion resistance of the surface of various materials after coating, electroplating, anodizing, anti-rust oil and other anti-corrosion treatment.

Standards

CNS3627, 3885, 4159, 7669, 8886, JISD-0201, H-8502, H-8610, K-5400, Z-2371, ISO 3768, 3769, 3770, ASTMB-117, B-268, GB-T2423, GJB 150.

Material

1. 5MM imported gray and white impact resistant PVC board which has high temperature resistance up to 85°C, corrosion resistance.

2. Support shelf is φ10MM glass fiber rod, which has corrosion resistance. Plastic-steel V-shaped brackets and fiber rods is placed at an angle to ensure that the test object is inclined at 15-30 degrees.

3. Pressure bucket adopts seamless welding by 2.0MM SUS304 stainless steel plate.

4. Using titanium alloy heating tube for heat generation, long service life and high corrosion resistance.

5. The cover is made up of 5MM imported transparent (YLIS from German) acrylic board which has fine workmanship, beautiful appearance and high transparency.

Specification

|

Model

|

DHL-120

|

|

Volume

|

960L

|

|

Interior dimensions(mm) (L*W*H)

|

1200*1000*600

|

|

Exterior dimensions(mm) (L*W*H)

|

1950*1250*1400

|

|

Temperature range

|

1. Laboratory temperature: 35°C~50°C which can be set arbitrarily

2. Pressure bucket temperature:47°C~63°C which can be set arbitrarily

|

|

Heating rate

|

1. Laboratory room temperature~35°C for about 35 minutes

2. Pressure bucket room temperature~47°C for about 15 minutes

|

|

Temperature accuracy

|

±1°C

|

|

Power

|

AC220V 50HZ 20A

This machine is suitable for neutral salt spray test (NSS) and corrosion test (AASS, CASS)

|

System and Structure

System

1.Control System

(1)Adopted Japan IEC high-speed CPU with stable performance, safety and reliability.

(2)Adopting LED digital tube displaying make sure that it has the humanization interface and all information is clear at a glance.

(3)Multi-fault warning protection system promises that it has anti-dry heating, anti-overheating

(4)Adopted high-power SSR output, imported sterling silver relay contacts with a service life to 106.

(5)Multiple time modes, S, M, H can be switched as users' requirement.

(6)Multi-control mode is set for continuous/discontinuous/manual/automatic testing.

(7)With manual/automatic demist mode to ensure that the salt mist can’t be leaked, so as to avoid corrosion of the laboratory.

(8)Hidden correction method ensures that absolute temperature is under control.

(2)Adopting LED digital tube displaying make sure that it has the humanization interface and all information is clear at a glance.

(3)Multi-fault warning protection system promises that it has anti-dry heating, anti-overheating

(4)Adopted high-power SSR output, imported sterling silver relay contacts with a service life to 106.

(5)Multiple time modes, S, M, H can be switched as users' requirement.

(6)Multi-control mode is set for continuous/discontinuous/manual/automatic testing.

(7)With manual/automatic demist mode to ensure that the salt mist can’t be leaked, so as to avoid corrosion of the laboratory.

(8)Hidden correction method ensures that absolute temperature is under control.

2.Water Replenishing system

Automatic/manual water charging system, with the function of automatic/manual replenishment when the water level is insufficient.

The experiment will be not interrupted which can be met the diverse environmental requirements for users (Automatic water

replenishment only needs to be connected with water pipe).

The experiment will be not interrupted which can be met the diverse environmental requirements for users (Automatic water

replenishment only needs to be connected with water pipe).

3.Heating Mode

Direct steam heating.it has the feature of quick heating speed, uniform temperature distribution, and less stand-by time.

4.Controlling mode

Touch controlling standard operation. With full detection fault pre-warning system. Lights up when fault occurs. Built-in manual

defogging function, can be placed or viewed during the experiment to remove the experimental accumulation of salt spray.

defogging function, can be placed or viewed during the experiment to remove the experimental accumulation of salt spray.

Structure

1.Safety Protection Device

With double over-temperature protection (KGB from Italy), the heating power can be switched off automatically in the event of temperature control meter fault or a heating system fault. Avoid overheating damage on the instrument.

Double low water level protection prevents dry burning from damaging on the heat pipe of laboratory and pressure bucket

with overload short circuit protection, which also can prevent damage on the instrument and internal electronic control accessories when an exception occurs. (Equipped the low salt level warning of the brine bucket while doing experiment to avoid experimental abnormalities after the brine is finished.)

Double low water level protection prevents dry burning from damaging on the heat pipe of laboratory and pressure bucket

with overload short circuit protection, which also can prevent damage on the instrument and internal electronic control accessories when an exception occurs. (Equipped the low salt level warning of the brine bucket while doing experiment to avoid experimental abnormalities after the brine is finished.)

2.

Dosage barrel

It is built fog collection bucket inside. Compared to the traditional external type, it is less likely to be damaged.

3.Nozzle

The nozzle is adopted precise quartz glass which can be guarantee to be used for 4000 hours without crystallizing.The spray tower is equipped with a conical dispersive device, which has the functions of guiding fog, adjusting the amount of fog and evenly falling fog.

4.Sealing method

The inside and outside box is connected to the sealing groove, using water sealing to avoid salt spray leakage.

Details Images

Product packaging

Certifications

Hot Searches