- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220v/380v/as customer's request

-

Power:

-

0.75kw/1.5kw/32kw/0.2kw

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2500*1150*1200mm

-

Year:

-

This Year

-

Product name:

-

Tomato Sauce Making Equipment

-

Capacity:

-

500kg/h

-

Vortex air pump:

-

0.75kw*1

-

Crushing speed:

-

1400r/min

-

Flow:

-

1 T/h

-

Keywords:

-

Tomato Paste Production Line

-

Speed:

-

960r/min

-

Barrel diameter:

-

300 mm

-

Rotation speed:

-

800 rpm

-

Filter mesh aperture:

-

0.6 mm

Quick Details

-

Place of Origin:

-

Henan,China(Mainland)

-

Brand Name:

-

Honest

-

Type:

-

Tomato Paste Production Line

-

Voltage:

-

220v/380v/as customer's request

-

Power:

-

0.75kw/1.5kw/32kw/0.2kw

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

2500*1150*1200mm

-

Year:

-

This Year

-

Product name:

-

Tomato Sauce Making Equipment

-

Capacity:

-

500kg/h

-

Vortex air pump:

-

0.75kw*1

-

Crushing speed:

-

1400r/min

-

Flow:

-

1 T/h

-

Keywords:

-

Tomato Paste Production Line

-

Speed:

-

960r/min

-

Barrel diameter:

-

300 mm

-

Rotation speed:

-

800 rpm

-

Filter mesh aperture:

-

0.6 mm

Advanced Structure Tomato Sauce Maker / Tomato Paste Bottles Filling And Sealing Machine / Tomato Sauce Making Equipment

1.Bubble Washing Machine

This machine is mainly used for jujube, grape, and other vegetables, fish shrimp and other aquatic products to clean , is the first part of Tomato Sauce Production Line.

The principle of air bubble cleaning machine is mainly used in the case before the equipment enclosure note right amount water, through heating tube to heat the water, the raw material after a box body, the combination of will and bubble machine and water under the action of tumbling state, and with the net belt to constantly move forward, when out of the water, high-end with the spray head, high pressure washing.

(1) This Shrimp/Fish/Vegetable Cleaning Machine can give the raw material double wash: the bubble and the water spray generated from high pressure.

(2) The dirt and impurities on fish, shrimp and vegetables can be separated and intercepted by the filter.

(3) During the cleaning process, the water spray and the high pressure spray nozzle can give a continuous supply of water. And it’s convenient to adjust the water supply according to specific requirements.

2.Tomato Paste Ketchup Pulping Machine

Pulping Machine is suitable for tomatoes after crushing, kiwi, strawberry, apple, pear, and after pre-cooking softening of haw, jujube and other fruit beating separation. MDJ type to nuclear pulper not only conforms to the applicable scope of the DJ pulper, and suitable for all kinds of stone fruit to nuclear beating separation.

Is the main part of Tomato Sauce Production Line.

Features: 1, automatic slag slurry separation.

2, can be combined on the production line and single machine production.

3, contact with the material of parts with high quality stainless steel, meet the food hygiene.

3.Jacketed Kettle

All 304 stainless steel made,clean and sanitary.

With agitator and tiltable to max 90 degrees to discharge the food.

This jacketed kettle is being widely to process various kinds of food by mixing or cooking.

This machine includes: machine base,cooking Kettle(with agitator), tilting device and electric control box

4. Tomato Ketchup Filling Bag Packing Machine

1. Automatically complete all tasks such as measuring, bag making, filling, sealing, hot pressing batch number, cutting off and counting. Adopt back-sealing heat-sealing mode.

2. Chinese display screen control system, stainless steel box body, only need to set the required parameters (filling amount, bag length, etc.) in the displayable setting unit, and the control system will automatically optimize and match each action to achieve the best packaging speed .

3. A complete trademark pattern can be obtained when packaging color-coded packaging materials;

4. The machine is equipped with an automatic shutdown system for paper shortage, and it can automatically stop when the packaging material is finished.

5. Stepless adjustment of speed and bag length: The packaging speed and bag length can be adjusted steplessly within the rated range, without changing parts;

6. The design adopts a unique embedded seal, an enhanced heat-sealing mechanism, and an intelligent temperature controller for temperature control. It has a good heat balance and adapts to various packaging materials, with performance numbers, low noise, clear seal lines, and strong sealing;

7. Flat knife incision contains easy tearing device and optional free device (steel word coding).

|

Equipments |

Quantity |

P arameter |

|

Bubble Cleaning Machine |

1 |

Capacity: 200- 500kg/h

1. Dimensions: 2

5

00*1150*1200mm

|

|

Tomato crusher |

1 |

1. Capacity: 200-500kg/H 2. Crushing speed: 1400r/min 3. Crushing power: 1.5kw 4. Dimensions: 600*500*1600mm |

|

Screw Pump |

1 |

1.Power:0.75kw 2.Flow:1 T /h 3.Speed: 960r/min |

|

Tomato Pulping Machine |

1 |

1. Processing capacity: 200- 500 kg /h 2. Barrel diameter: φ 300 mm 3. Rotation speed: 800 rpm 4. Filter mesh aperture: 0.6 mm 5. Motor power: 1.5 kW 6. D imension: 1050 * 450 * 1350mm |

|

Screw Pump |

1 |

1.Power:0.75kw 2.Flow:1 T /h 3.Speed: 960r/min |

|

Preheating buffer tank |

1 |

1. Material: SUS304 2. Mixing motor: 0.75KW 3. Mixing speed: 36r/min 4. Dimensions: φ 900*1750mm 5. Tank structure: three layers with heating 6. Capacity: 500L |

|

Cooking Pot |

1 |

1. Model : HT-JCG 5 00 2. Capacity :5 00L 3. Power :32 KW 4. Voltage : 380V ,50hz 5. Dimension s: 1800*1500*1600 6. Weight : 260kg |

|

Empty bottle can handler |

1 |

1. Bottle handling speed: 35~50 cans/minute 2. Applicable bottle diameter: 35-130mm 3. Total power: 200W 4. Boundary dimension: 860mm * 800 * 840mm |

|

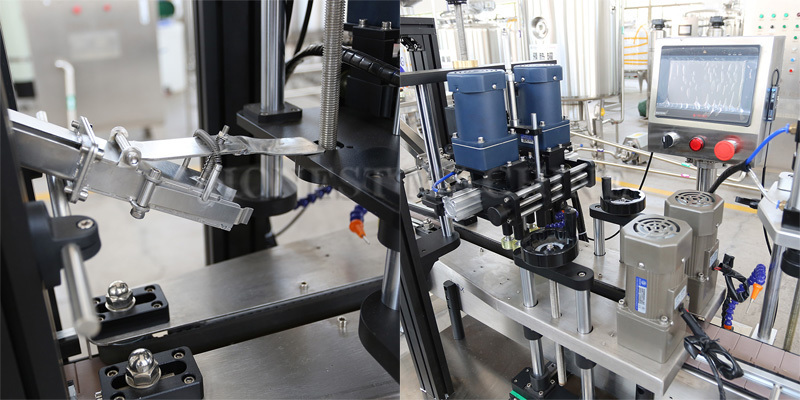

Continuous filling machine |

1 |

1. Filling range: 30ml-5000ml 2. Filling speed: 30-50 bottles/minute 3. Power: 1.5 KW 4. Overall dimensions:2000*1000*1400MM 5. Filling head: 1 |

|

Servo can sealing machine |

1 |

1. Number of cans: 1 2. Number of sealing rollers: 4 (2 first sealing rollers, 2 second sealing rollers) 3. Can sealing speed: 30-45 cans/min 4. Sealing height: 25-220mm 5. Can sealing diameter: 35-153mm 6. Working temperature: 0~45 ℃, working humidity: 35~85% 7. Working power supply: single-phase AC220V 50/60Hz 8. Total power: 1.7KW 9. Weight: 350KG (about) 10. Size: 2650 * 840 * 1650mm |

|

Glass can filling machine |

1 |

1.Number of filling heads 2 2.Filling capacity 10-100ml, 30-300ml, 50-500ml, etc 3.Production capacity 10-30 bottles/minute 4.Filling accuracy ≤ ± 1% 5.Power 380V50HZ, 1.2 KW 6.Working pressure 0.4-0.7Mpa 7.Overall size 2000*1000*1600 8.Machine weight 500kg |

If you need further information, please contact us freely, we will do our best to cooperate with you.