- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V,220V

-

Power:

-

15KW (Host)

-

Dimension(L*W*H):

-

3600*2000*1600 or As per model

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product 2024

-

Paper roll:

-

3-24 layers

-

Coating method:

-

Fully automatic glue

-

Speed control:

-

Computer frequency conversion

-

Winding diameter:

-

30--300mm

-

Reel speed:

-

3-16m/min

-

Wall thickness:

-

1-15mm

-

Control way:

-

Host operation panel

-

After Warranty Service:

-

Online support,Free spare parts,Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE, ISO

Quick Details

-

Production Capacity:

-

30 set/month

-

Processing Type:

-

paper core tube machine

-

Place of Origin:

-

Henan,China

-

Brand Name:

-

Shunfu

-

Voltage:

-

380V,220V

-

Power:

-

15KW (Host)

-

Dimension(L*W*H):

-

3600*2000*1600 or As per model

-

Weight:

-

10000 kg

-

Marketing Type:

-

Hot Product 2024

-

Paper roll:

-

3-24 layers

-

Coating method:

-

Fully automatic glue

-

Speed control:

-

Computer frequency conversion

-

Winding diameter:

-

30--300mm

-

Reel speed:

-

3-16m/min

-

Wall thickness:

-

1-15mm

-

Control way:

-

Host operation panel

-

After Warranty Service:

-

Online support,Free spare parts,Video technical support

-

After-sales Service Provided:

-

Field installation, commissioning and training

-

Certification:

-

CE, ISO

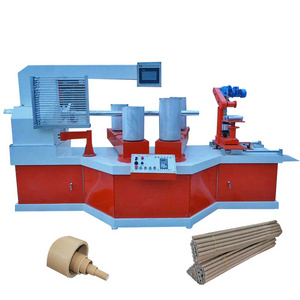

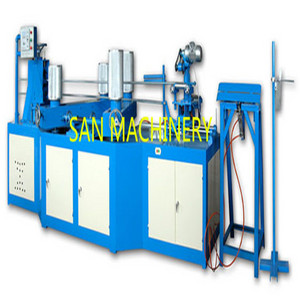

2/4 Heads Automatic Parallel Paper Tube Making Machine with Paper Tube Cutter

Custom paper tube machines, serve your needs and boosts your business!

SHUNFU Paper Core Machine is professional and high speed equipment for producing paper tubes. The machine adopts the synchronous slitting principle and has the advantages of high speed, length-adjustable, less length-tolerance, energy saving, self-drying, low noise, tight winding and neat slitting edge. It is possible to add one color-printing unit to this machine if required. SHUNFU Paper Core Making Machine is the first choice for professional paper core winding factories and paper processing factory to increase the efficiency and paper tube quality.

Features:

1. Main structure made by thicker steels which are finished by processing of re-cutting and welding, make machine much more stable and strong.

2. Main transmission adopt gear speed cut, low-noise, low-heating, high revolution, high torque.

3. Main motor adopt Vectorial high torque inverter speed adjusting.

4. Equipped with Hydraulic device to adjust belt tension, with belt tension sensor and belt angle sensor, both can be adjusted automatically.

5. Equipped with synchronous cutting system, cutting table adopt high precision ball screw and high performance server motor drive.

6. Equipped pulse length fixation control, cooperated with front feedback compensation function, can make sure the same length in different producing speed.

7. Adopt double PLC control systems, IO output control and functional operation control separately, to increase cutting reaction speed, cutting length is much more accurate.

8. Equipped with new control panel and big size colorful main machine touching interface .

9. with multi functional bottom paper feeding device, will stop once paper break.

10. Equipped with integral paper reel stand, glue stand, paper feeding assembly, all are electrical control.

11. Design of modularization electric layout makes use,maintaining and repairing more convenient and scientific.

Firstly, the raw materials are set up to be fed in the machine. The paper that is used is generally 4 inches wide. Depending upon the number of layers, the thickness of the core will vary. The paper rolls are set up at certain angles to ensure seamless spiralling. Then the strips of paper go through a pan of glue. Later they are wound together around a mandrel at an angle. The inner diameter of the core depends upon the size of the mandrel. Finally, as the core comes out of the mandrel a blade which is moving at the same speed as the core, cuts it into required sizes.

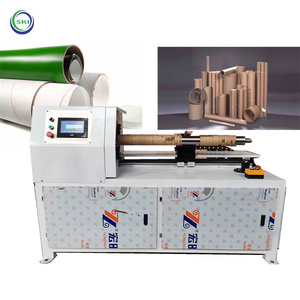

AUTOMATIC PAPER CORE CUTTING MACHINE to recut jumbo length paper cores into smaller width cores

- Various cutting options can be easily programmed Burr free fine

- cutting Output : Approx. 20 cuts per minute depending upon the core sizes and cutting width

- Operator : One person

Toilet paper core, tape, aluminium foil, plastic foil, film stretches, electrical wires, fabric, cellophane tapes, disposable paper products, dental floss cores, foam, thermal transfer ribbon, stickers and many other products need a cardboard tube core.

If you are interested in our machine, pls contact us freely and let us know the below your requirements

| 1: | Your raw material is big jumbo kraft paper or bobbin kraft paper jumbo roll paper? |

| 2: | What is the thickness of the paper tube you produce? (mm) |

| 3: |

What is the inner diameter of the paper tube you produce? (mm) |

| 4: | What's the length of the paper tube you produce? (mm) |

We are not only supply paper core making machine, but also other paper making machinery.If you are interested in it, pls contact us freely.

- Kraft Paper Making Machine Line

- Paper Board Machine Line

- Egg Tray Making Machine Line

- Toilet Paper Making Machine Line

- Toilet Paper Rewinding Machine

- Toilet Paper Slitting Machine

- Napkin Paper Machine

Our expertise in understanding the specific needs of customers helps us to meet their expectation levels in terms of quality standards. This enhances our credibility and makes us one of the most successful manufacturers and suppliers in the industry.

Our machines are successfully installed in more than 60 countries across the globe including Mexico, Sri Lanka,Nigeria, Bangladesh, Egypt,Thailand, Turkey, Singapore, Malaysia, Kuwait, Kenya, Zambia, Saudi Arabia, U.A.E, Brazil, Syria, South Africa, Iran, Libya, Ghana, Sudan, Russia, Bulgaria, Indonesia and USA etc.