- Product Details

- {{item.text}}

Quick Details

-

Color:

-

Black,Red,Blue...it can be customized

-

Type:

-

One-side with Skin or Both-side with Skin

-

Feature:

-

Eco-friendly,Shockproof,Waterproof,Moistureproof,Elasticity

-

Adhesive Tape:

-

3M,Tesa,Nitto,Duplocoll...

-

Shape:

-

original bun, block, sheet, rolls, one-side skin and both-side skin

-

Certification:

-

RoHS,REACH,EN71,ISO/TS16949

-

Application:

-

Automobile, airconditioning, refrigerator, home application

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Product name:

-

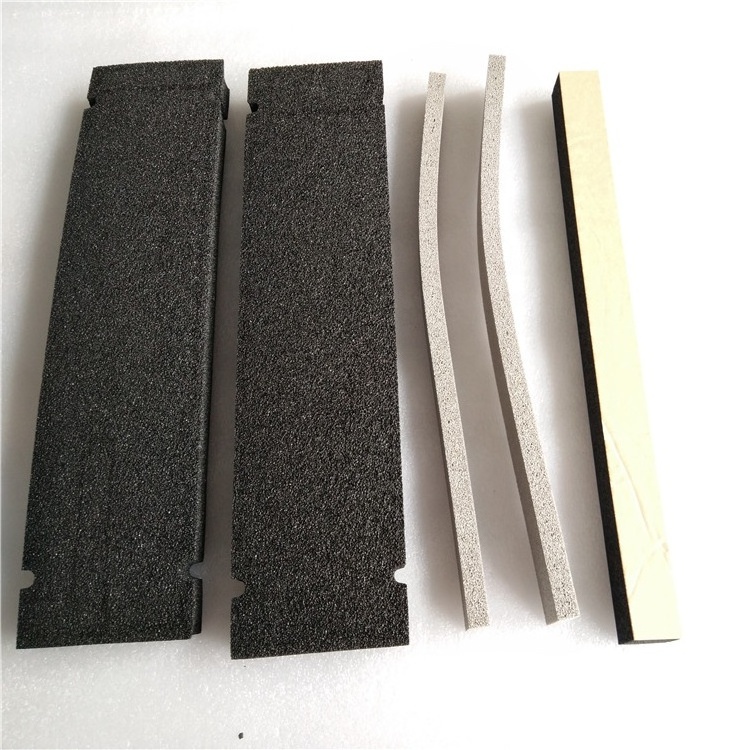

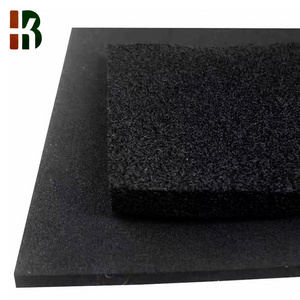

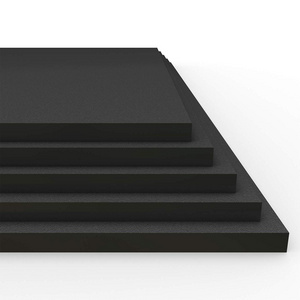

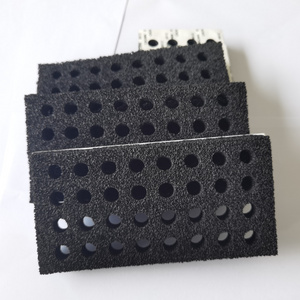

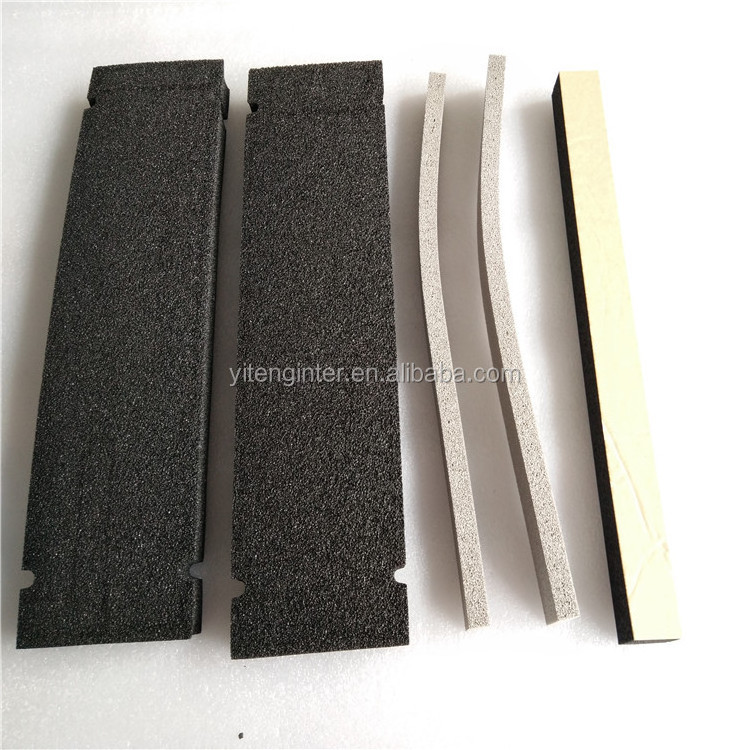

Black Oxidation Resistance Sealing EPDM/NBR Open Cell Foam

-

Density:

-

55-90KG/M3

-

Color:

-

Black,Red,Blue...it can be customized

-

Type:

-

One-side with Skin or Both-side with Skin

-

Feature:

-

Eco-friendly,Shockproof,Waterproof,Moistureproof,Elasticity

-

Adhesive Tape:

-

3M,Tesa,Nitto,Duplocoll...

-

Shape:

-

original bun, block, sheet, rolls, one-side skin and both-side skin

-

Certification:

-

RoHS,REACH,EN71,ISO/TS16949

-

Application:

-

Automobile, airconditioning, refrigerator, home application

NBR ( nitrile -butadiene rubber) and PVC ( Poly Vinyl Chloride) is the main mixture material in plastic-rubber foam industry. NBR/PVC mixture has both PVC’s feature ozone resistance and NBR’s feature oil resistivity except of its performance of crosslinking, plus a bit fire resistance. It also functions with good physical property. Due to sourceful and inexpensive PVC as raw material, such blended foam is widely used in many fields.

NBR seal rubber has two kinds: closed cell NBR foam and open cell NBR foam. NBR seal rubber is closed cell pore material of high elastic performances; NBR material has the good performances: bending resistance, cold resistance, heat resistance, flame retardant, waterproof, low thermal conductivity, shock absorption, shock proof, and sound insulation.

Characteristics

- Clearly boost the attributes of ozone-resistance and weatherability

- Improve the functions of tensile strength, elongation, tear resistance, heat resistance and fire resistance.

- Further the performances of oil resistivity, resistances to some chemicals

- Expand the possibility of extrusion and drawability,self-vulcanization resistance to strengthen its storage stability

- Easy to tint, made colorfully

| Name | Nitrile Rubber (NBR) Foam | Compression Set(%)(50%/72h at 23℃) | <=40 |

| State | One-side with Skin or Both-side with Skin | Certification | RoHS,SVHC,EN71,ISO/TS16949 |

| Odour | Slight plastic taste | MOQ | 1pcs |

| Colour | Black,Red,Blue.. | Port | Shanghai or ... |

| Density(Kg/m3) | 55-90 | Useful Life | According to density,indoor or outdoor,temperature |

| Heat Shrinkage Rate(70℃X4hrs)% | <=8 | Product Performance | Good elastic&compressive,good buffering,impact resistance,ANTI-UV,corrision resistance,low temperature resistant,sound insulation,sealing,flame retardant,fire proof |

| Temperature Resistance(Cold Crack to High Intermittent)(C) | -40~120 | ||

| Tensile Strength(Kpa) | >=120 | Application | Application:HAVC and Insulations,Energy conservation,Electrical protection/insulation,Vapour/frost barrier,Sound deadening,Anti vibration,Pipe work insulation(Hot and cold),Data cable protection/insulation,Refrigeration |

| Elongation(%) | >=500 | ||

| Flame Retardant(mm/min) | <=100 |

Product Performance

- Good elastic&compressive,good buffering,impact resistance,ANTI-UV,corrision resistance,low temperature resistant,sound insulation,sealing,flame retardant,fire proof

Application

- HAVC and Insulations,Energy conservation,Electrical protection/insulation,Vapour/frost barrier,Sound deadening,Anti vibration,Pipe work insulation(Hot and cold),Data cable protection/insulation,Refrigeration

Technological Process

- Raw material stired and mixed→Heating,foaming→Length,Width,Thickness Cutting→Function Inspection→Initial Adhesion Testing(Testing Equipment)→Constant Adhesion Testing(Tesing Equipment)→Punching→Size Testing→Silent Dust→Packing(Customer Request)→Shipment

Packaging Details

- OPP bag and Carton or customized

Why Choose us

- Free sample

- We can cooperate and give you the competitive price to help you developing your market

- Delivery time:5-7 days

- High quality,precise product technology with excellent service