- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/415V/400V

-

Weight:

-

550 KG

-

Dimension(L*W*H):

-

1800*600*1600mm

-

ITEM:

-

machine to make wood briquette

-

Raw material:

-

wood chips,sawdust,branches,straw,peanut shell etc.

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical

-

Function:

-

briquette making machine

-

Raw material size:

-

Below 3mm

-

Keyword:

-

Coal stick cubic briquettes extrusion machine

-

Product name:

-

charcoal powder making machine

-

raw material moisture:

-

30-40%

-

Briquette diameter:

-

10-80 mm

-

Capacity:

-

1-10ton/h

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

AOLS

-

Voltage:

-

380V/415V/400V

-

Weight:

-

550 KG

-

Dimension(L*W*H):

-

1800*600*1600mm

-

ITEM:

-

machine to make wood briquette

-

Raw material:

-

wood chips,sawdust,branches,straw,peanut shell etc.

-

Briquette Shape:

-

Hexagonal Hollow Cylindrical

-

Function:

-

briquette making machine

-

Raw material size:

-

Below 3mm

-

Keyword:

-

Coal stick cubic briquettes extrusion machine

-

Product name:

-

charcoal powder making machine

-

raw material moisture:

-

30-40%

-

Briquette diameter:

-

10-80 mm

-

Capacity:

-

1-10ton/h

Biomass Fuel Coffee Grounds Carbon Powder Extruder Sugar Cane Bagasse Olive Pomace Cotton Stalks charcoal powder making machine

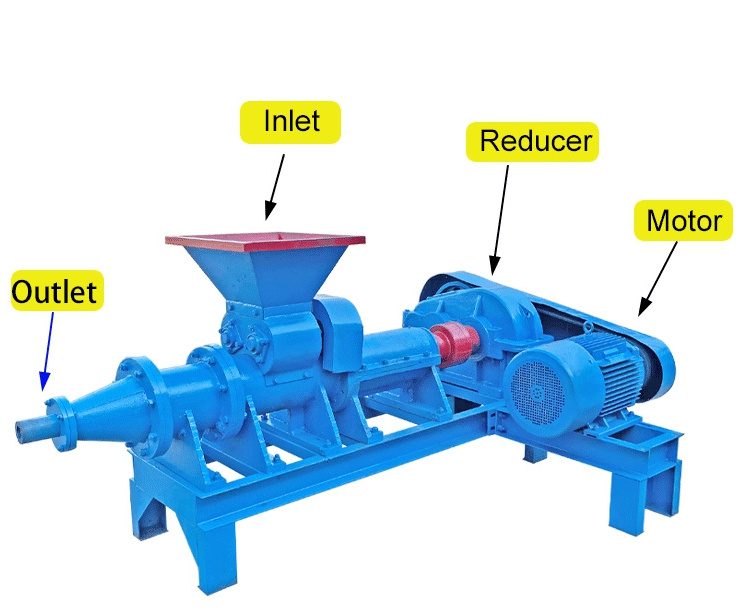

Our briquette extruder machine, which also called briquettes extruding machine use the application of the principle of the spiral extrusion , which make it become a certain intensity round or hexagon, triangle, ect charcoal/coal rods by working for the powered coal/charcoal mixed with binder. With our self researched formula, the briquette is smokeless, high density and easy to be ignited. It is widely used in chemical industry, metallurgy and ceramic industry, which is the ideal equipments of enterprise specialized in efficient production and reducing consumption.

Charcoal briquette press extruder machine production line

the process is Carbonize -- Crushing --Mixing--Extruding--Drying

Charcoal crusher: It is used to pulverize biomass charcoal into powder. The powder is less than 5mm.If your raw material is less than 5mm. You can go directly to the next process without choosing to smash.

Grinding wheel mixer: The mixer is an important machine in the production line. We mainly use this machine to mix the charcoal powder and the binder together. The material processed by this machine is easy to shape.

Charcoal briquetting machine: The charcoal briquetting machine is the most important machine in this production line. Many shapes you want can be produced, such as cylindrical, square column, hexagonal, square, etc.

Drying equipment: This drying equipment is used to dry the formed raw materials.

Applicable Materials

Equipment Warrior

From the design, we will do every step carefully to satisfy clients to the best.

- Manufacturer Service

Provide goods based on customer's need.

Can print customer Logo on the machine according the customer.

We provide all spare parts for all machines in lifetime use.

- Sales Service

Price Term: Price can be based on EXW,FOB,CFR,CIF,DDU etc.

Payment Term:T/T. L/C, Western Union ,Credit Card,Pay from Alibaba.

Guarantee terms:Quality guarantee term for one year,exclude wear part.

- Online Service

Timely response online by whatsapp,Trademanager or Wechat.

Keep in touch by email, phone.

- Shipping Service

Transportation:Shipping by LCL,FCL by sea transport.

Packing:Packing by export wooden box or loading by container.

Delivery time:3-7 days ,after deposit,Special circumstance will notify.

Shipping:we can be responsible for the shipping ,also accept client shipping agent.

Shipping port:Tianjin,Qingdao,Shanghai,Guangzhou etc.