- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

different models

-

Weight:

-

750 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Gold

-

Product name:

-

shaking table, shaker table

-

Keywords:

-

Centrifugal Gold Concentrtor

-

Name:

-

Shaker Table

-

Quality:

-

High Leavel

-

Usage:

-

Separate Gold

-

Certification:

-

ISO9001:2008

-

Machine type:

-

Metal Ore Gravity Beneficiation Equipment

Quick Details

-

Production Capacity:

-

90% Recovery Rate

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

ASCEND

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

different models

-

Weight:

-

750 KG

-

Marketing Type:

-

New Product 2023

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Application:

-

Gold

-

Product name:

-

shaking table, shaker table

-

Keywords:

-

Centrifugal Gold Concentrtor

-

Name:

-

Shaker Table

-

Quality:

-

High Leavel

-

Usage:

-

Separate Gold

-

Certification:

-

ISO9001:2008

-

Machine type:

-

Metal Ore Gravity Beneficiation Equipment

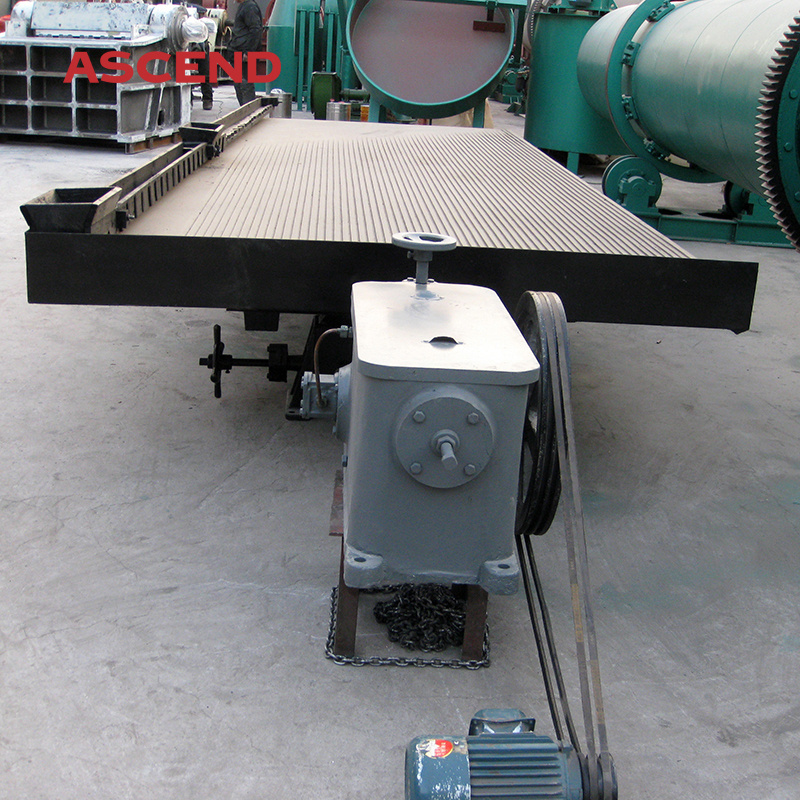

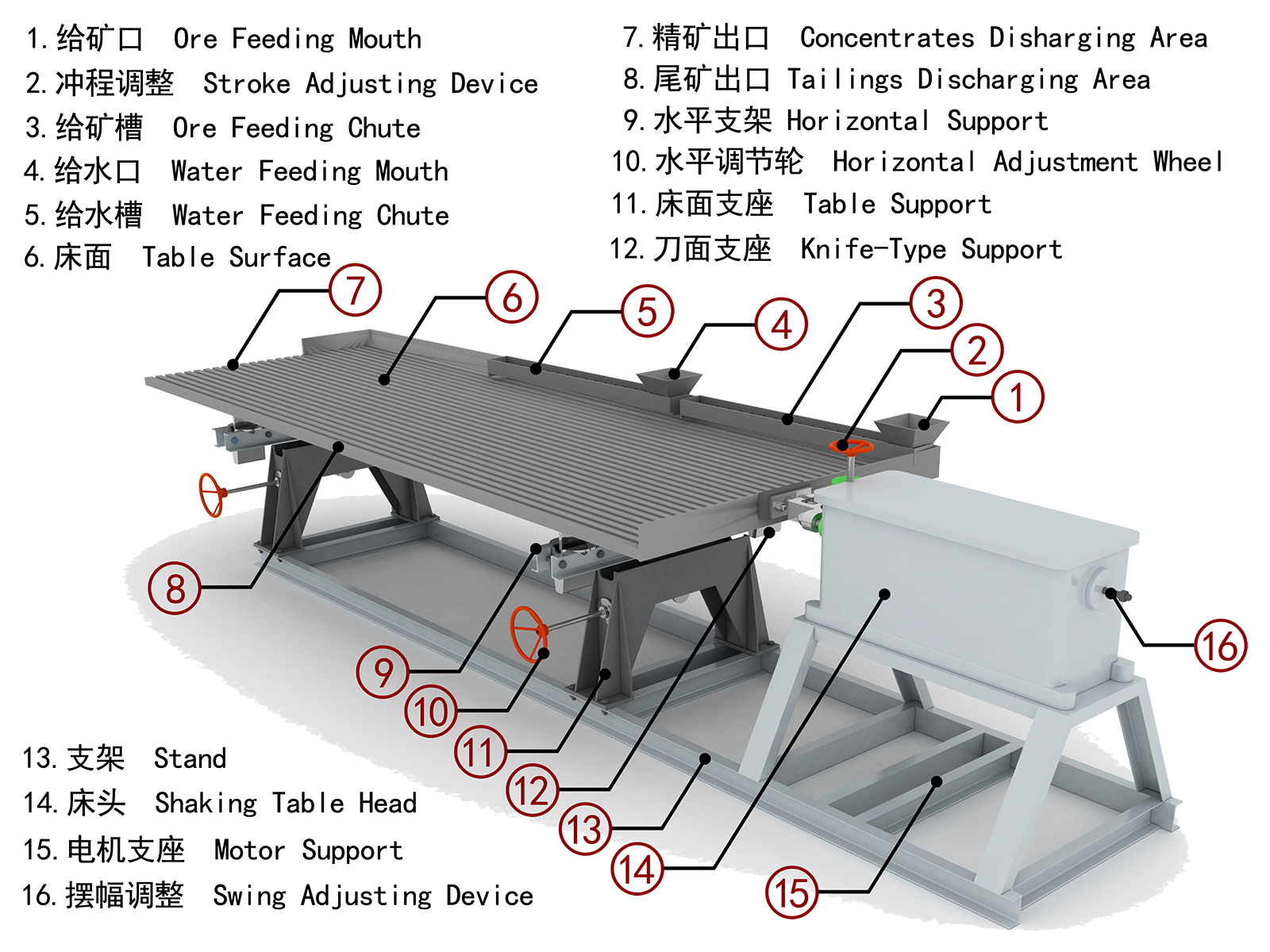

6-s mineral ore shaking table

Gold refining Shaking Table as one of gravity mining equipment, 6S shaking table is widely applied on separating

Gold, Manganese, Chrome, Lead, Zinc, Mercury, Auluminum and rare metals, the noble metal ore, also applied on sorting coal, ect.

6S shaking table can be usedin different stages in mining, like rough concentration, retreat and scanvenging.

Recovery material size ranges are: coarse sand (0.5 mm to 2 mm), fine sand (0.074 mm to 0.5 mm) and slime (-0.074 mm). Effective mineral recovery size range is 0.22 mm to 2 mm.

The working principle of Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove),to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

| Model | Storke(mm) | Feed Size(mm) | Feed density | Capacity(t/h) | Power | Weight(kg) |

| 6S-4550×1200×1546 | 8-22 | 2-0.074 | 15-30 | 0.6-2.5 | 1.1 | 800 |

| LY-3000×1620×1360 | 6-30 | 2-0.074 | 10-30 | 0.4-1.5 | 1.1 | 550 |

| LY-2100×1050×850 | 12-28 | 2-0.074 | 10-30 | 0.3-0.8 | 1.1 | 350 |

| LY-1100×500×430 | 9-17 | 2-0.074 | 10-30 | 0.05-0.2 | 0.55 |

150

|

Every year, we will send our technical engineer to customer working site, help customers make installation, commission and other after sales service issue. Customer satisfaction is our ultimate pursuit!

Q1: Are you trading company or manufacturer?

A: We are factory.

Q2: How long is your delivery time?

A: Generally it is 7-10 days if the goods are in stock. or it is 15-30 days if the goods are not in stock, it is according to quantity.

Q3: What is your payment method?

A: 30% of total price should be paid by T/T as down payment; 70% balance payment should be paid by T/T before delivery.

Q4: What Information should customers give us, So that we can be able to provide you suitable quotation and service.

What minerals are you separating?

What's the maximum size of your raw minerals?

How much capacity do you need per hour for your project?

A: The warranty period of crusher equipments is one year. and we will supply the spare parts for you at lowest cost.