- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2.2kw

-

Weight:

-

1500

-

Dimension(L*W*H):

-

2000*1200*1800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

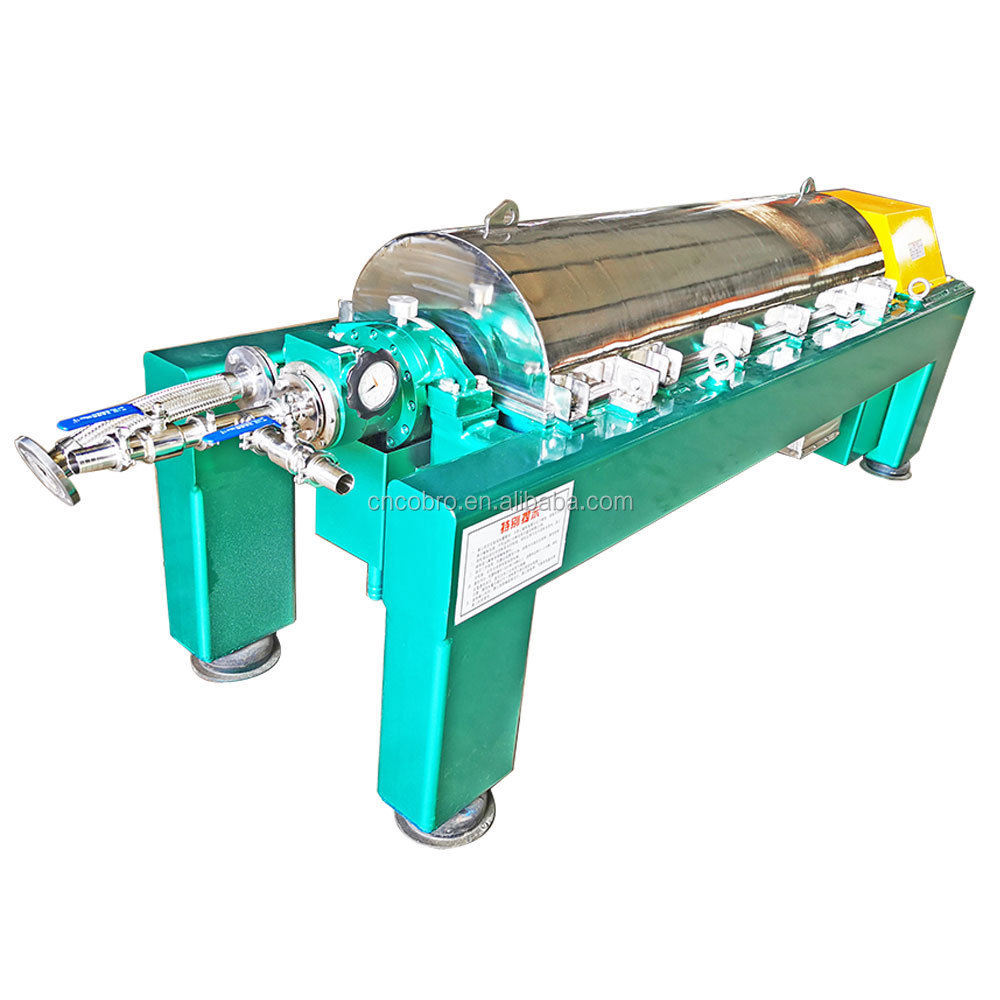

3 phase decanter centrifuge

-

Application:

-

Liquid Liquid Solid Separation

-

Machine type:

-

Centrifugal Solid- Liquid Separator

-

Function:

-

Liquid Liquid Soild Centrifge

-

Capacity:

-

1~10T

-

Speed:

-

2300-4800rpm

-

Diameter:

-

220-650mm

-

Draw ratio:

-

3-4.3

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

PL

-

Voltage:

-

380V

-

Power:

-

2.2kw

-

Weight:

-

1500

-

Dimension(L*W*H):

-

2000*1200*1800mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Name:

-

3 phase decanter centrifuge

-

Application:

-

Liquid Liquid Solid Separation

-

Machine type:

-

Centrifugal Solid- Liquid Separator

-

Function:

-

Liquid Liquid Soild Centrifge

-

Capacity:

-

1~10T

-

Speed:

-

2300-4800rpm

-

Diameter:

-

220-650mm

-

Draw ratio:

-

3-4.3

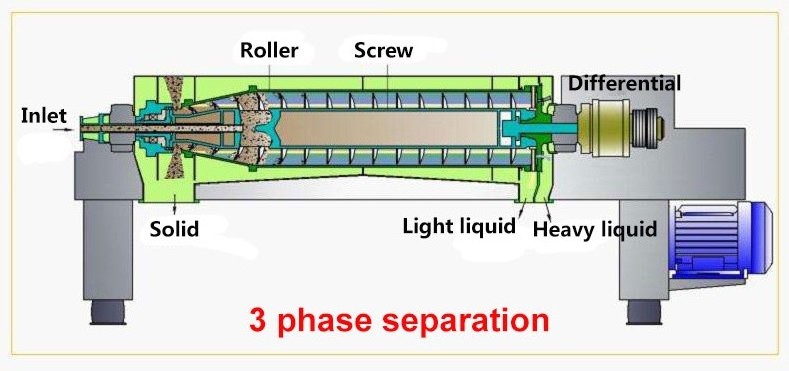

Working principle

Drum and screw are working with higher speed at a certain differential rotation. Material is transported into spiral tube continuously , accelerated after the rotary drum, in under the action of centrifugal force field, the heavier solid deposit formed in the drum wall sediment layer.The feeding screw continuously pushes the solid phase of the deposit to the drum cone, and then out of the drain.The lighter liquid phase forms the inner liquid ring, which is continuously overflowed by the large end of the drum, and is discharged through the drain outlet.The machine operates at full speed, continuously feeding, separating, washing and discharging.It has the characteristics of compact structure, continuous operation, stable operation, strong adaptability, large production capacity and convenient maintenance.It is suitable for the suspension with solid phase particle size greater than 0.005mm and concentration range of 2-40%.Widely used in chemical industry, light industry, pharmaceutical, food, environmental protection and other industries.

Application

-

-Solid phase dehydration: dehydration effect for processing materials of solid particles.

--Particle size classification: used in the removal of material of large diameter solid particles.

--Liquid clarification: used for removing solid particles in the suspension liquid are clarified.

Technical paramenter

|

Model

|

Diameter(mm)

|

Speed(rpm)

|

Length(mm)

|

Separation ratio

|

Output(m3/h)

|

Power(KW)

|

Weight(Kg)

|

Dimension(L*W*H)

|

|

LW220×660

|

220

|

4800

|

660

|

2840

|

0.3~1.5

|

7.5~11

|

700

|

1580×1100×650

|

|

LW220×930

|

220

|

4800

|

930

|

2840

|

0.5~2

|

11~15

|

900

|

1800×1100×650

|

|

LW350×1050

|

350

|

4000

|

1050

|

3100

|

2~6

|

11~15

|

1200

|

2450×1350×900

|

|

LW350×1470

|

350

|

4000

|

1550

|

3100

|

2~10

|

15~18.5

|

1800

|

2600×1860×900

|

|

LW400×1200

|

400

|

3400

|

1200

|

2580

|

4~10

|

18.5~22

|

1800

|

2400×1860×950

|

|

LW400×1750

|

400

|

3400

|

1750

|

2580

|

5~15

|

18.5~22

|

2200

|

3300×1500×1100

|

|

LW450×1350

|

450

|

2800

|

1350

|

1980

|

8~15

|

15~22

|

2200

|

2750×1550×1100

|

|

LW450×1940

|

450

|

2800

|

1940

|

1980

|

8~20

|

22~30

|

2500

|

3300×1550×1100

|

|

LW530×1590

|

530

|

2500

|

1590

|

1860

|

10~20

|

22~30

|

2600

|

3230×1600×1100

|

|

LW350×2270

|

530

|

2500

|

2270

|

1860

|

10~30

|

30~37

|

3000

|

3750×1600×1100

|

|

LW620×1950

|

650

|

2300

|

1950

|

1830

|

15~30

|

37~45

|

4500

|

3950×1750×1350

|

|

LW620×2800

|

650

|

2300

|

2800

|

1830

|

15~45

|

37~45

|

5500

|

4600×1750×1350

|