- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DIXIN

-

Voltage:

-

380 V 3 Phase 60Hz or as your requirement

-

Dimension(L*W*H):

-

5.8 m*1.3 m*1.0 m for 11 row stations

-

Weight:

-

3.2 kg

-

Warranty:

-

one year warranty and lifelong technical support

-

Feeding width:

-

925-1200mm, 1250 mm or 1000 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine style:

-

roof sheet making machine

-

Feeding thickness:

-

0.3-0.8 mm metal steel

-

Cover width:

-

1050 or 840mm

-

Main frame:

-

300 H/U steel

-

Produce speed:

-

8-12 m/min

-

Control system:

-

Auto PLC control system

-

Cutting style:

-

Hydraulic post cutting

-

Cutting mould material:

-

Cr12 mould steel with quenched treatment

Quick Details

-

Type:

-

Tile Forming Machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

20M/MIN

-

Rolling thinckness:

-

0.3-0.8mm

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

DIXIN

-

Voltage:

-

380 V 3 Phase 60Hz or as your requirement

-

Dimension(L*W*H):

-

5.8 m*1.3 m*1.0 m for 11 row stations

-

Weight:

-

3.2 kg

-

Warranty:

-

one year warranty and lifelong technical support

-

Feeding width:

-

925-1200mm, 1250 mm or 1000 mm

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Machine style:

-

roof sheet making machine

-

Feeding thickness:

-

0.3-0.8 mm metal steel

-

Cover width:

-

1050 or 840mm

-

Main frame:

-

300 H/U steel

-

Produce speed:

-

8-12 m/min

-

Control system:

-

Auto PLC control system

-

Cutting style:

-

Hydraulic post cutting

-

Cutting mould material:

-

Cr12 mould steel with quenched treatment

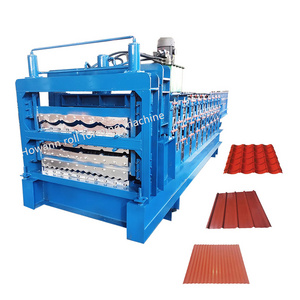

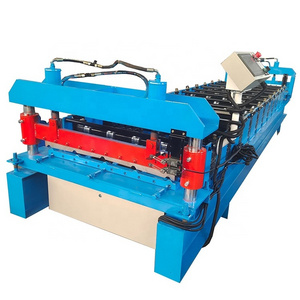

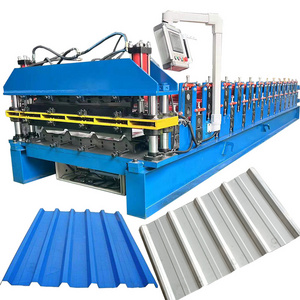

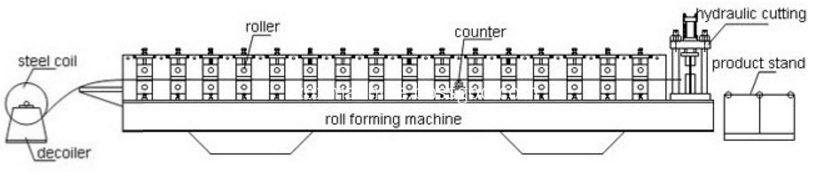

Roof Sheet Making Machine Metal Roofing Sheet Roll Forming Machine

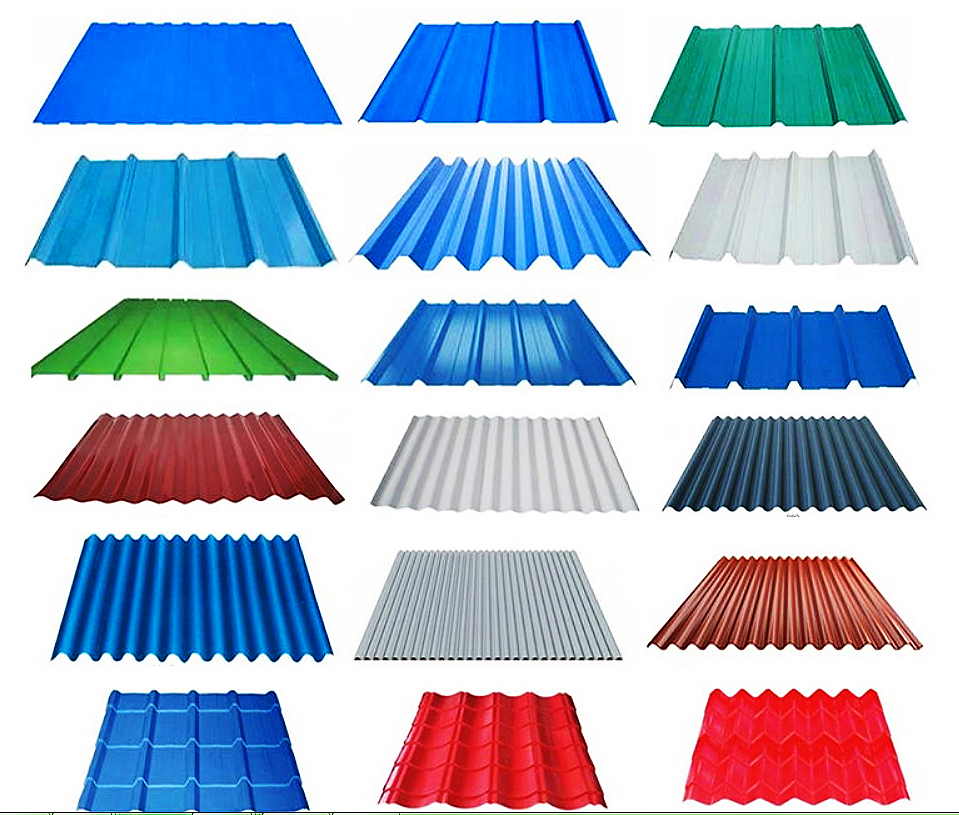

Roof panels

840-210-25 roof panel

or one more wave length wider 840+210=1050mm 1050-210-25 roof panel.

1050-210-25 roof making machine can produce both 840-210-25 and

1050-210-25 roof sheet

Main Parameters

| No. | ||

| 1 | Suitable material | color steel sheet, galvanized steel sheet, aluminium sheet |

| 2 | Material width | 1000mm or as your required |

| 3 | Material thickness | 0.3-0.8 or as your required |

| 4 | Working speed | 20/min, can be 20-25m/min |

| 5 | Main motor power | 5.5kw with cycloidal with reducer |

| 6 | Hydraulic pump power | 4kw |

| 7 | Electrical control system | PLC control system with inverter |

| 8 | Shaft diameter | 75mm |

| 9 | Roller station | 15 rows, depend on your panel profile drawing |

| 10 | Roller | high grade 45# steel, hard chrome plating |

| 11 | Working time | 24 hours |

| 12 | workers | 1-2 only |

| 13 | Cutting head material | Cr 12 mould steel with quenched treatment |

| 14 | Voltage | 380V 3Phase 50Hz or as your required |

| 15 | Weight | 3.5T |

| 16 | The machine size | 7000mm*1500mm*1500mm |

Product Pictures

Hot Searches