- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

as customized

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V

-

Product name:

-

banana chips making machines

-

Material:

-

304 stainless steel

-

Function:

-

banana chips production line

-

Usage:

-

potato chip machine

-

Shape:

-

chips production line

-

Motor:

-

air, electric,desile

-

Output:

-

as customized

-

Feature:

-

fruit and vegetable processing machines

-

Final Products:

-

plantain processing machines

-

Key words:

-

banana chips making mahcine

Quick Details

-

Machinery Capacity:

-

Customized

-

Brand Name:

-

HDF

-

Year:

-

2021

-

Dimension(L*W*H):

-

as customized

-

Weight:

-

2000 KG

-

Place of Origin:

-

Henan, China

-

Voltage:

-

220V

-

Product name:

-

banana chips making machines

-

Material:

-

304 stainless steel

-

Function:

-

banana chips production line

-

Usage:

-

potato chip machine

-

Shape:

-

chips production line

-

Motor:

-

air, electric,desile

-

Output:

-

as customized

-

Feature:

-

fruit and vegetable processing machines

-

Final Products:

-

plantain processing machines

-

Key words:

-

banana chips making mahcine

Banana Chips Making Production Line Cheaper Plantain Processing Machine

Product Description

1.Product Description

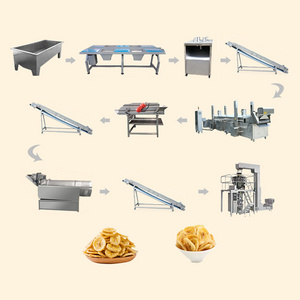

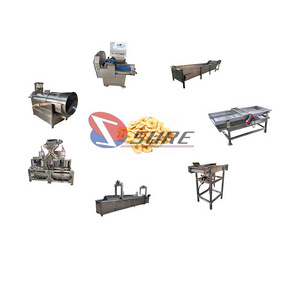

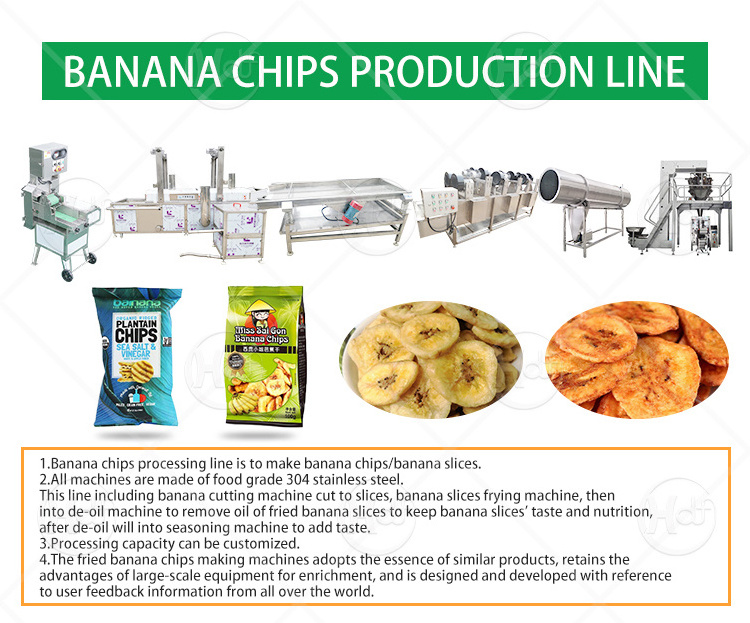

1.Banana

ch

ips processing line is to make banana chips/banana slices.

2.All machines are made of food grade 304 stainless steel,

This line including banana cutting machine cut to slices, banana slices frying machine, then into de -oil machine to remove oil of fried banana slices to keep banana slices' taste and nutrition,after de-oil will into

seasoning machine to add taste.

3.Processing capacity can be customized.

4.The fried banana chips making machines adopts the essence of similar products, retains the advantages of large -scale equipment for enrichment, and is designed and developed with referenceto user feedback information from all over the world.

2.All machines are made of food grade 304 stainless steel,

This line including banana cutting machine cut to slices, banana slices frying machine, then into de -oil machine to remove oil of fried banana slices to keep banana slices' taste and nutrition,after de-oil will into

seasoning machine to add taste.

3.Processing capacity can be customized.

4.The fried banana chips making machines adopts the essence of similar products, retains the advantages of large -scale equipment for enrichment, and is designed and developed with referenceto user feedback information from all over the world.

Final Product Show

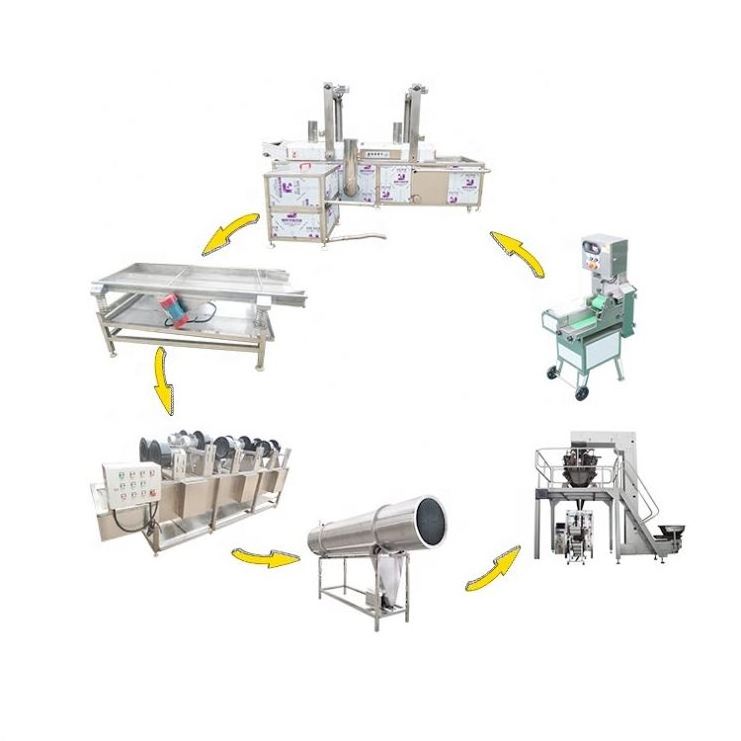

Process of banana chips production line:

Banana Chip Production Line Introduction Deep-fried banana chips are snacks that are washed, peeled, sliced, fried and seasoned with fresh banana chips. It not only retains the special taste of roasted bananas, but also has rich nutritional value, delicious and convenient.

hoisting→cleaning and peeling→picking→hoisting→cutting→washing→blanching→air cooling&dewater→frying→deoiling→air

cooling→seasoning→conveyor→packaging

Banana Chip Production Line Introduction Deep-fried banana chips are snacks that are washed, peeled, sliced, fried and seasoned with fresh banana chips. It not only retains the special taste of roasted bananas, but also has rich nutritional value, delicious and convenient.

hoisting→cleaning and peeling→picking→hoisting→cutting→washing→blanching→air cooling&dewater→frying→deoiling→air

cooling→seasoning→conveyor→packaging

Recommend Products

Why Choose Us

1.WHO IS HUAFOOD?

Henan Huafood Machinery Technology Co., Ltd. is a food machinery factory integrating production, Qualification of the company manufacturing and sales for 18 years. The company has passed the ISO9001 international certification, the main products have passed the CE certification, the products have reached more than 50 patents, with the right of self import and export. Our technique has been widely applied to produce the following products: Frying machine, vegetables and fruits cleaning machine,vegetable cutting machine, french fries/potato chips production line, seasoning and coating machine, drying equipment,pasteurization line, chicken feet production line, conveyor, hoist, vibrating screen, food packing machine and so on.

2.

Our factory has Strictly control the source of raw materials, stable and reliable raw material supplier.

There are 201, 304 and 316 stainless steel materials on the market, we can provide all three.

All metal materials included in our standard offer are

304 stainless steel

(

strong corrosion resistance (can contact acid, alkaline materials such as salt, kelp, tomatoes), not easy to rust.

)

3.

Our products have passed

Multiple

international certifications.

Packing & Delivery

1.Our workers will strictly implement our packing system to ensure that the products are not damaged during transportation.

2.

There are many modes of transportation to ensure that products reach customers on time.

|

Delivery Way

|

Delivery Time

|

|

By air

|

About10-20 days days after leaving the port

|

|

By sea

|

About20-30 days days after leaving the port

|

Our Service

1.

Convenient method of payment

2.I

ndividual service

①

Video that teaches customers how to operate the machines will be upload on Youtube.

②

. OEM/ODM Available.

③

.Any inquiries will be replied within 12 hours.

④

.Fastest delivery: Sample order in stock and 3-7 days for mass production.

Cooperating Clients

WHO CHOOSE US?

Hot Searches