- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Stainless steel, carbon steel or other metal

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Dimensions:

-

Customer's drawings or samples

-

Machining Process:

-

CNC Precision Machining

-

Quality control:

-

100% inspected, third party inspection available

-

Certification:

-

Both material and dimension report

-

Service:

-

OEM\ODM

-

Application:

-

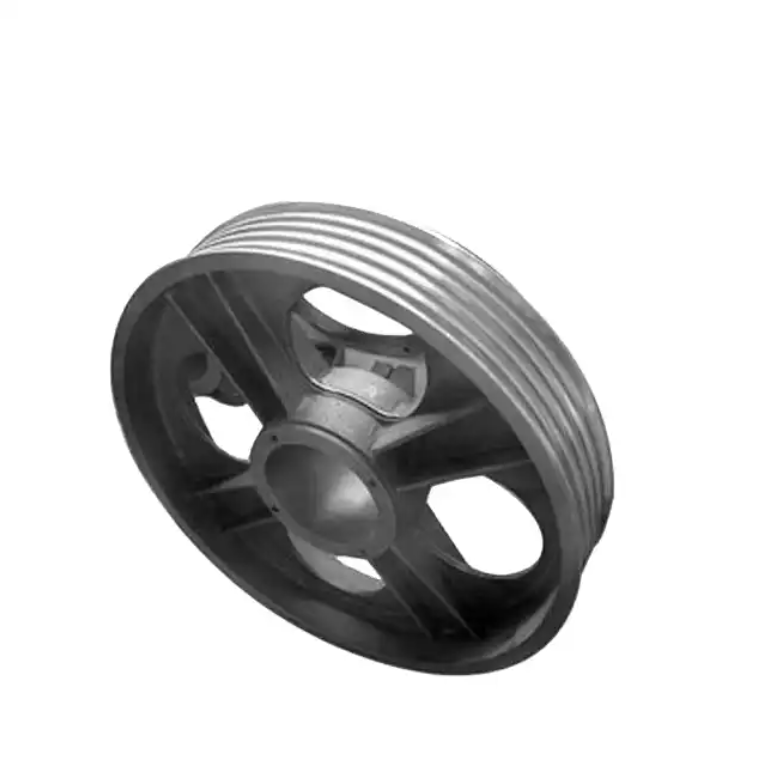

Car

-

MOQ:

-

300PCS

-

Packing:

-

Poly Bag + Inner Box +Wooden box

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

OEM

-

Model Number:

-

Flywheel

-

Material:

-

Stainless steel, carbon steel or other metal

-

Drawing format:

-

2D/(PDF/CAD)3D(IGES/STEP)

-

Dimensions:

-

Customer's drawings or samples

-

Machining Process:

-

CNC Precision Machining

-

Quality control:

-

100% inspected, third party inspection available

-

Certification:

-

Both material and dimension report

-

Service:

-

OEM\ODM

-

Application:

-

Car

-

MOQ:

-

300PCS

-

Packing:

-

Poly Bag + Inner Box +Wooden box

Details Images

Products Description

|

Material Type

|

Standard Specification

|

|

|

|

|

|||

|

Alloy Types

|

DIN (W-Nr)

|

AISI

|

ASTM

|

BS3100

|

JIS

|

|||

|

|

|

|

ACI

|

BS3146

|

|

|||

|

Stainless Steel

|

1.4305

|

303

|

|

303S21

|

SUS303

|

|||

|

|

1.4308

|

304

|

CF-8

|

ANC3A

|

SCS13

|

|||

|

|

1.4306

|

304I ,

|

CF-8

|

304C12

|

SCS19A

|

|||

|

|

1.4408

|

316

|

CF-8M

|

ANC4B

|

SCS14A

|

|||

|

|

1.4404

|

316L

|

CF-3M

|

316C12

|

SCS16A

|

|||

|

|

G-X10Cr13

|

410

|

CA-15

|

410C12

|

SCS1

|

|||

|

|

1.4507

|

431

|

|

ANC2

|

SUS431

|

|||

|

|

1.4581

|

318

|

CF-8C

|

ABC4C

|

SCS21

|

|||

|

|

|

17-4PH

|

CB7Cu-1

|

|

SCS24

|

|||

|

Carbon steel&low alloy steel

|

1.0416GS-38

|

1020

|

415-205

|

CLAIA

|

SC410

|

|||

|

|

1.0446GS-45

|

1025

|

WCB

|

CLAIB

|

SC450

|

|||

|

|

GS-34CrMo4

|

4135

|

|

|

SCM435

|

|||

|

|

GS-42CrMo4

|

4140

|

|

CLA3

|

SCM440

|

|||

|

|

|

8620

|

|

805A20

|

SNCM220

|

|||

|

Heat-resistant steel

|

GX40CrNiSi2512

|

|

HH

|

|

SCH13

|

|||

|

|

|

|

HU

|

309C35

|

|

|||

|

|

G-X15CrNiSi2520

|

|

HK30

|

331C40

|

SCH21

|

|||

|

|

G-X40CrNiSi2521

|

|

HK40

|

310C40

|

SCH22

|

|||

|

|

G-X40CrNiSi3525

|

|

HP

|

|

SCH24

|

|||

|

High Manganese

|

G-X120Mn13

|

|

B-3

|

BW-10

|

|

|||

|

|

|

|

B-1

|

SCMnH2

|

|

|||

|

Tool Steel

|

100MnCrW4

|

|

01

|

B01

|

SKS3

|

|||

|

|

4Cr5MoSiV1

|

|

H13

|

BH13

|

SKD61

|

|||

|

|

W6Mo5Cr4V2

|

|

M2

|

BM2

|

SKH9

|

|||

|

Copper Alloys

|

C85400

|

|

|

|

|

|||

|

|

C86200

|

|

|

|

|

|||

|

|

C90500

|

|

|

|

|

|||

|

|

C83600

|

|

|

|

|

|||

|

|

C95800

|

|

|

|

|

|||

|

Tolerance

|

ISO8062 CT6-CT8

|

|

Surface Treatment

|

Electroplating, Chrome plating, Zinc plating, Nickel plating, Electrophoresis, Polishing, Sandblasting, Passivation, Powder coating, Spray painting, hot dip zinc coating, Etc.

|

|

Quality Assurance

|

ISO9001, TS16949

|

|

Inspection

|

1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance

|

|

|

2.Third Party inspection available upon requirement

|

|

Main Testing Facility

|

Three-dimensional measuring instrument(CMM),Salt spray test box, Dynamic balance detector, Pneumatic detection, Mechanical properties test machines, Nondestructive test equipments

|

|

Features & Advantage

|

1.High strength and not easy to deform, has good electrical and thermal conductivity

|

|

|

2.High finish appearance,smooth surface roughness is Ra1.6 after machining

|

|

|

3.No granules, no spots and no surface coating peel off in appearance

|

|

|

4.Good corrosion resistance

|

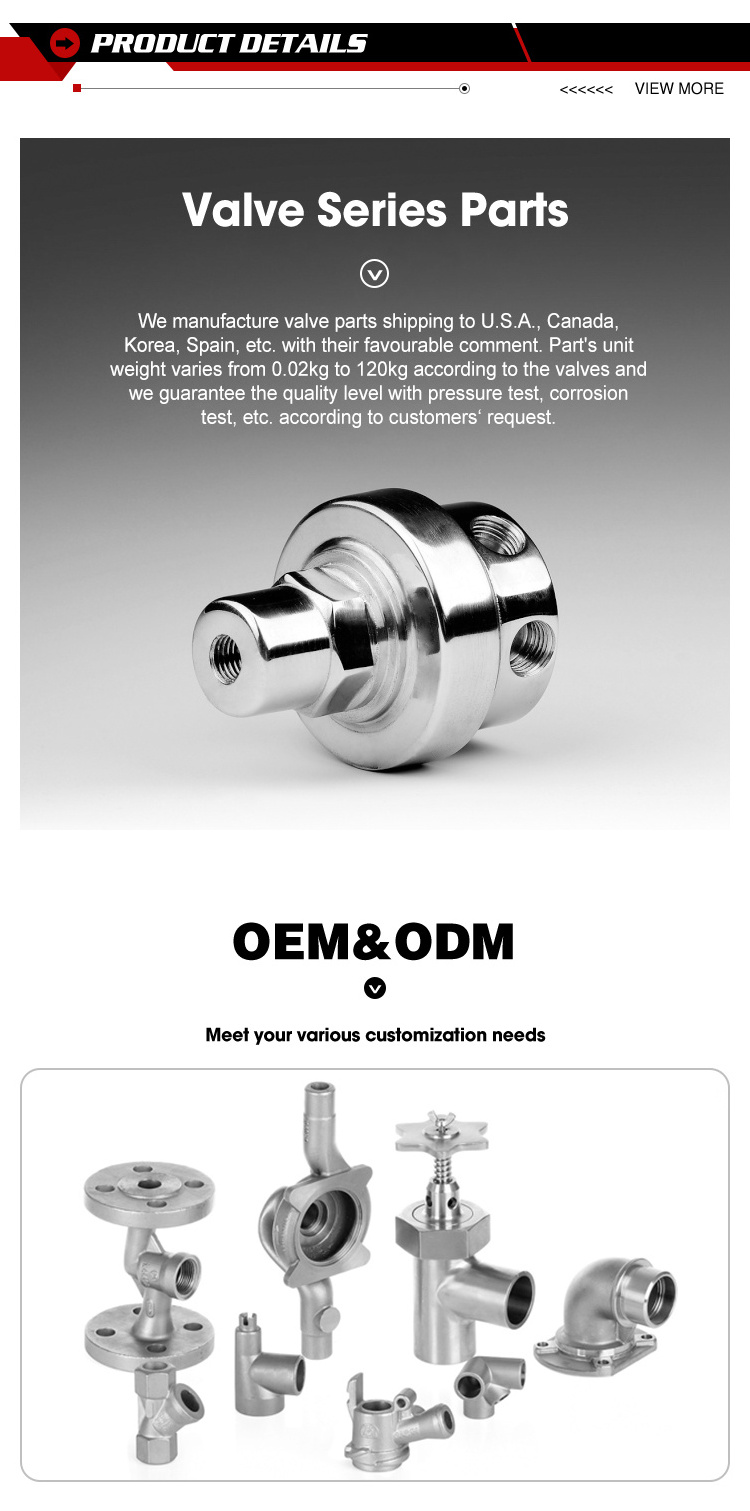

Two types of investment cast processes: Silica Sol process and the water glass process.

The Silica Sol process is used to cast complex high quality parts with requirements of a very good surface finish and close

dimensional tolerances.

This process can range from a weight of just a few grams to approximately 50 kilograms . If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations.

The water glass process is typical of the process in the early stages of investment castings. It generally is capable of much larger castings than the Silica Sol process, but does not have as good of surface finish or tolerances. The water glass process provides parts that have better surface finish and dimensional tolerances than sand castings.

This process may range in weight from several grams to approximately 120 kilograms .

First article layouts and spectrometer material certifications are provided with all first article samples.

Custom service: A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

dimensional tolerances.

This process can range from a weight of just a few grams to approximately 50 kilograms . If you are concerned with precision in very small parts, we are especially proficient at very fine detail work including teeth and serrations.

The water glass process is typical of the process in the early stages of investment castings. It generally is capable of much larger castings than the Silica Sol process, but does not have as good of surface finish or tolerances. The water glass process provides parts that have better surface finish and dimensional tolerances than sand castings.

This process may range in weight from several grams to approximately 120 kilograms .

First article layouts and spectrometer material certifications are provided with all first article samples.

Custom service: A variety of secondary operations can be performed on both types of investment castings. They include heat treatment, machining, plating, painting, polishing and buffing, assembly services and even custom packaging.

Recommend Products

Hot Searches