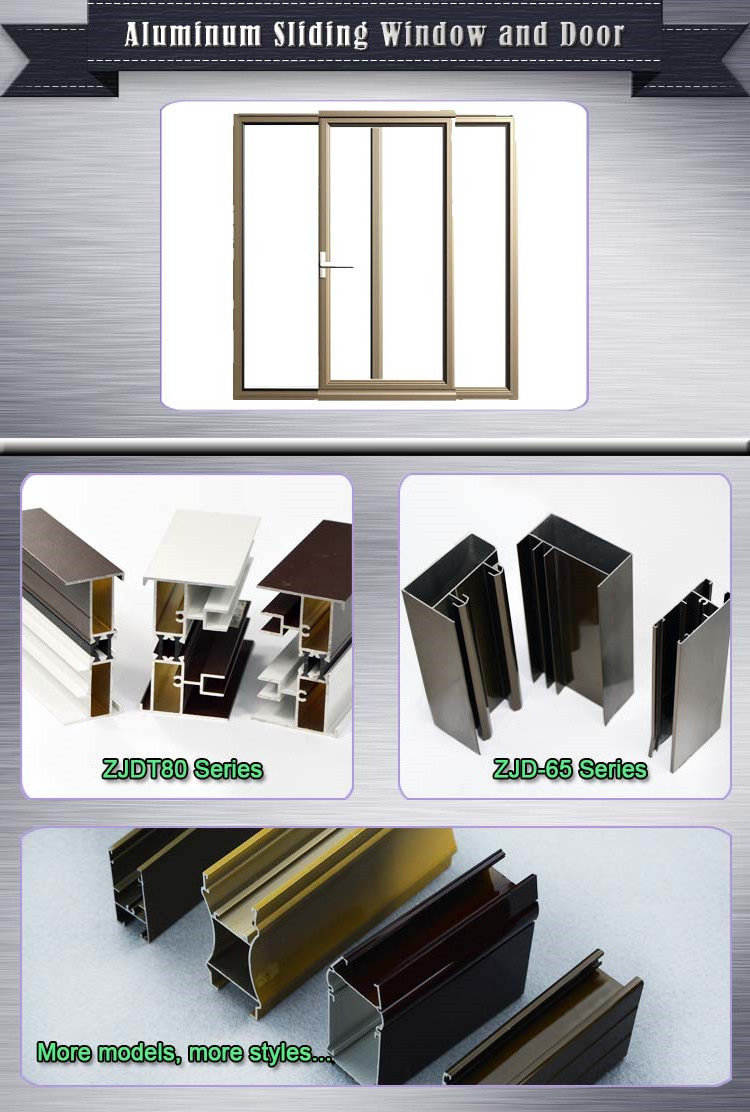

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

ZJD

-

Brand Name:

-

Zhongjda

-

Product name:

-

perfiles de aluminio para puertas y manparas

-

Certification:

-

ISO9001:2008;ISO14001:2004

-

Length:

-

Max 6.0m or customized

-

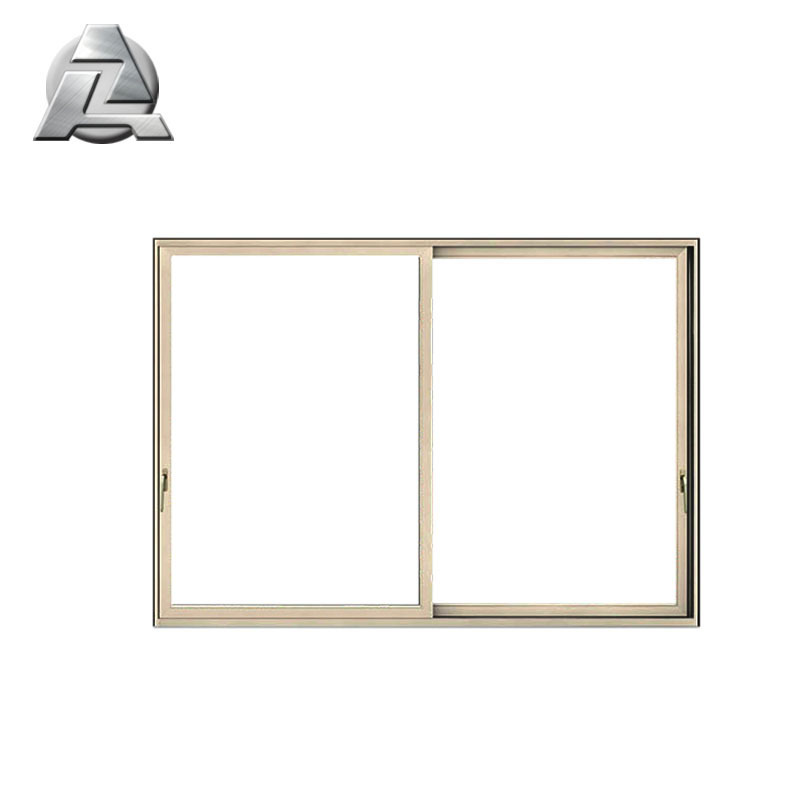

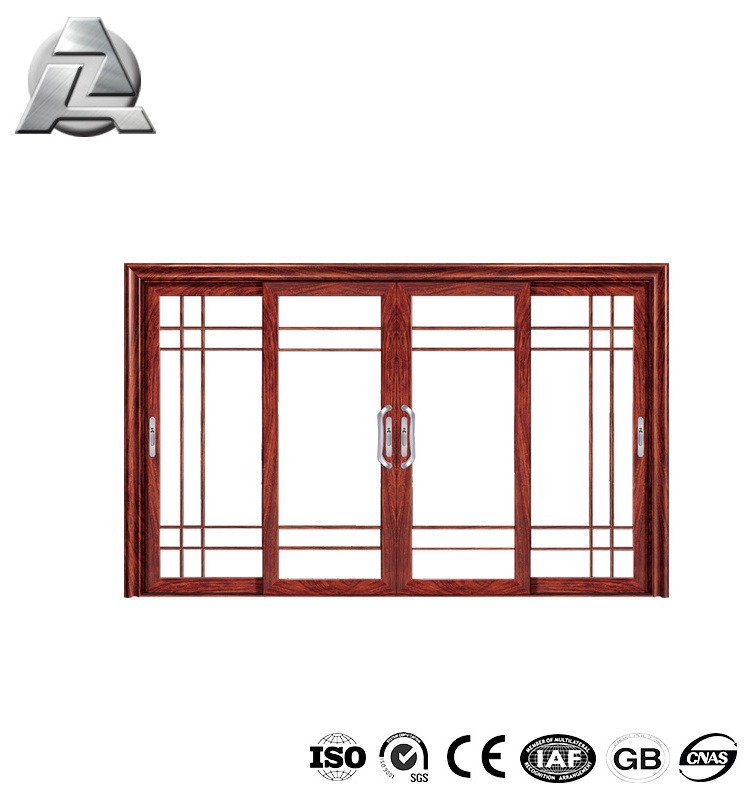

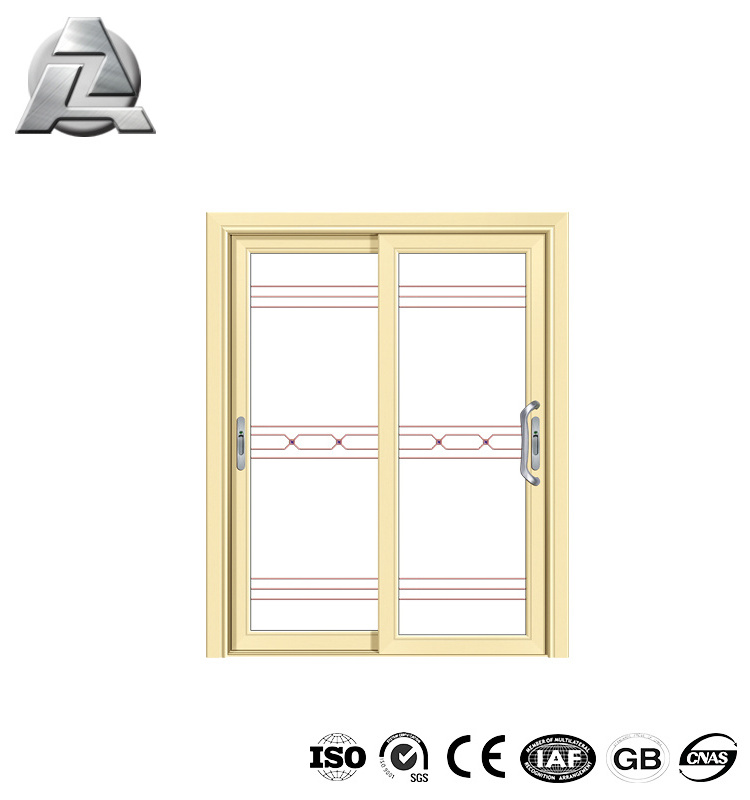

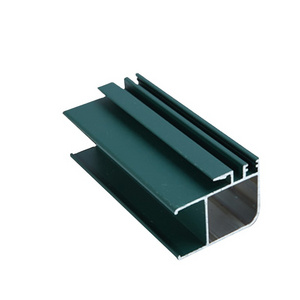

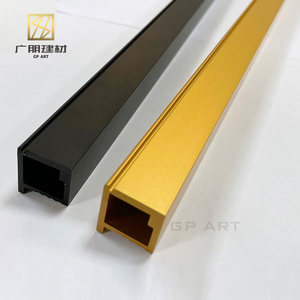

Color:

-

white,brown,gray,wood grain finish,custom colors

-

Range of styles:

-

available to suit every application

-

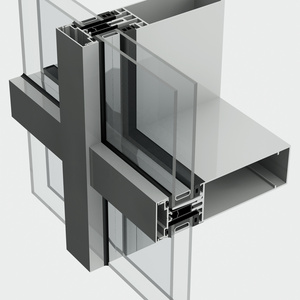

Thermal break:

-

Polyamide or PVC

-

Wall thickness:

-

1.4mm for windows 2.0mm for doors

-

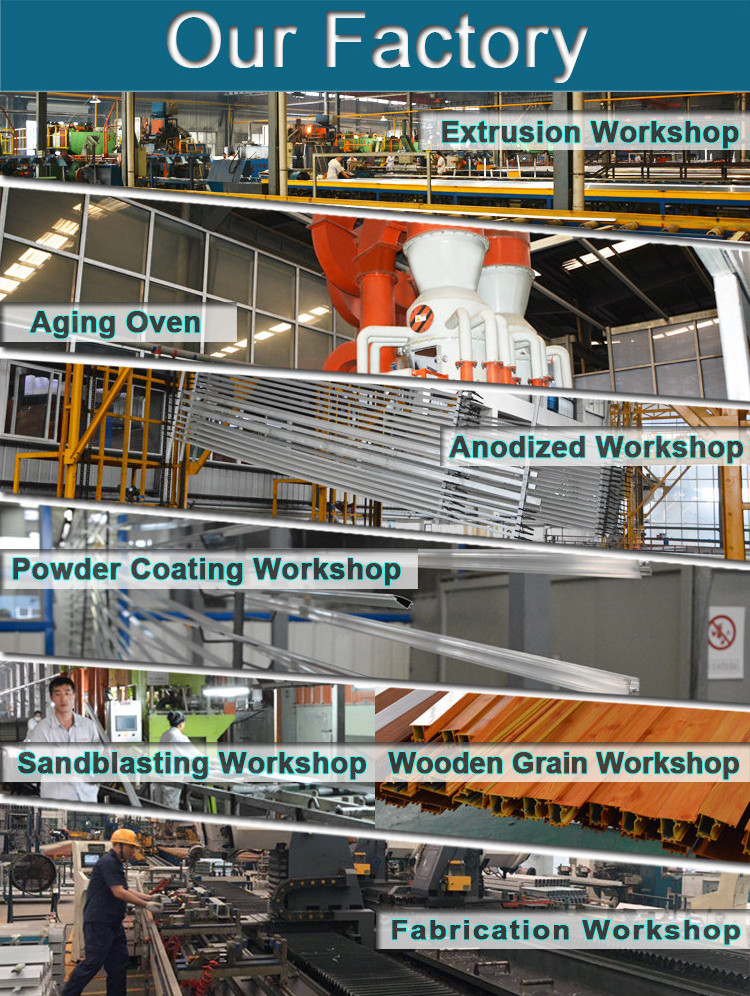

Finish:

-

Mill,Anodizing,Powder coating,Wooden color

-

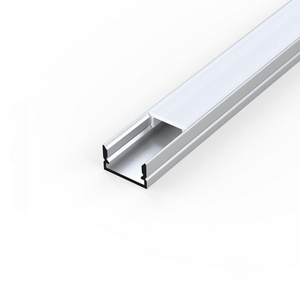

Name:

-

aluminum window frame parts extrusion manufacturers

Quick Details

-

Grade:

-

6000 Series

-

Tolerance:

-

±5%

-

Place of Origin:

-

Liaoning, China

-

Model Number:

-

ZJD

-

Brand Name:

-

Zhongjda

-

Product name:

-

perfiles de aluminio para puertas y manparas

-

Certification:

-

ISO9001:2008;ISO14001:2004

-

Length:

-

Max 6.0m or customized

-

Color:

-

white,brown,gray,wood grain finish,custom colors

-

Range of styles:

-

available to suit every application

-

Thermal break:

-

Polyamide or PVC

-

Wall thickness:

-

1.4mm for windows 2.0mm for doors

-

Finish:

-

Mill,Anodizing,Powder coating,Wooden color

-

Name:

-

aluminum window frame parts extrusion manufacturers

aluminum window frame parts extrusion manufacturers

SUPPLYING YOU WITH SOLUTIONS

Phone support

: speak to a friendly voice you trust to get the job done

Industry leading practises:

take the stress out of material control

On the case:

we make sure every order is chased

In the know:

one step ahead, recording the progress of your order

Comprehensive technology:

we use the latest technology to stay ahead

Mail us any time:

fast and reliable responses to inbound email

| Q1: What are the advantages of using the 6000 series of alloys in aluminum extrusions ? |

|

A: The 6000 series , which incorporates magnesium and silicon, provide good extrudability, strength, corrosion resistance, formability and machinability -- which explains why it’s also ZJD’s alloy of choice for all our aluminum extrusions . |

| Q2: If I wish to send an electronic drawing to you, what types of files can you accept? |

|

A: We accept many file formats such as DXF, DWG and IGES. |

|

Q3: Why do extrusion companies always ask me to sign off on a drawing before they can order tooling if I’ve already provided a drawing? |

|

A: Oftentimes, we find a few key dimensions that are missing from the original drawing that need to be clearly identified. Other times, we have taken exception to a tolerance, dimension, alloy, note, surface condition, etc. It’s just our way of documenting exactly what we have agreed upon. |

| Q4: What is the difference between anodized and mill finished ? |

|

A: Mill is the raw state of aluminum as extruded - no surface treatment. Anodized (also known as Satin Clear or Clear Anodized ) is an electrolytic process. This process increases

corrosion resistance and weather resistance.

|

| Q5: What About Anodizer Rack Marks? |

|

A: Electrical contact must be made to each part to be anodized . The more electrical current required, the greater the electrical contact. The size of the contact therefore

depends on the

anodizing

process and the size of the part being

anodized

.

|

|

Q6: What is your closest sea-port ?

|

|

A: Dalian City SeaPort .

|