- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V/380V/or customized

-

Dimension(L*W*H):

-

6110*2110*1570mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

7000 KG

-

name:

-

polyurethane foam die cutting machine manufacturer

-

column:

-

4

-

Cutting area:

-

1200mm*810mm

-

Cutting force:

-

100 tons

-

computer control:

-

yes

-

double-cylinder:

-

simple,fast,accurate operation

-

Stroke:

-

50-220mm

-

Application:

-

epe foam,sponge,pe foam,soundproof products

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

DAPENG

-

Machine Type:

-

Hydraulic cutting

-

Voltage:

-

220V/380V/or customized

-

Dimension(L*W*H):

-

6110*2110*1570mm

-

Power (kW):

-

7.5

-

Weight (KG):

-

7000 KG

-

name:

-

polyurethane foam die cutting machine manufacturer

-

column:

-

4

-

Cutting area:

-

1200mm*810mm

-

Cutting force:

-

100 tons

-

computer control:

-

yes

-

double-cylinder:

-

simple,fast,accurate operation

-

Stroke:

-

50-220mm

-

Application:

-

epe foam,sponge,pe foam,soundproof products

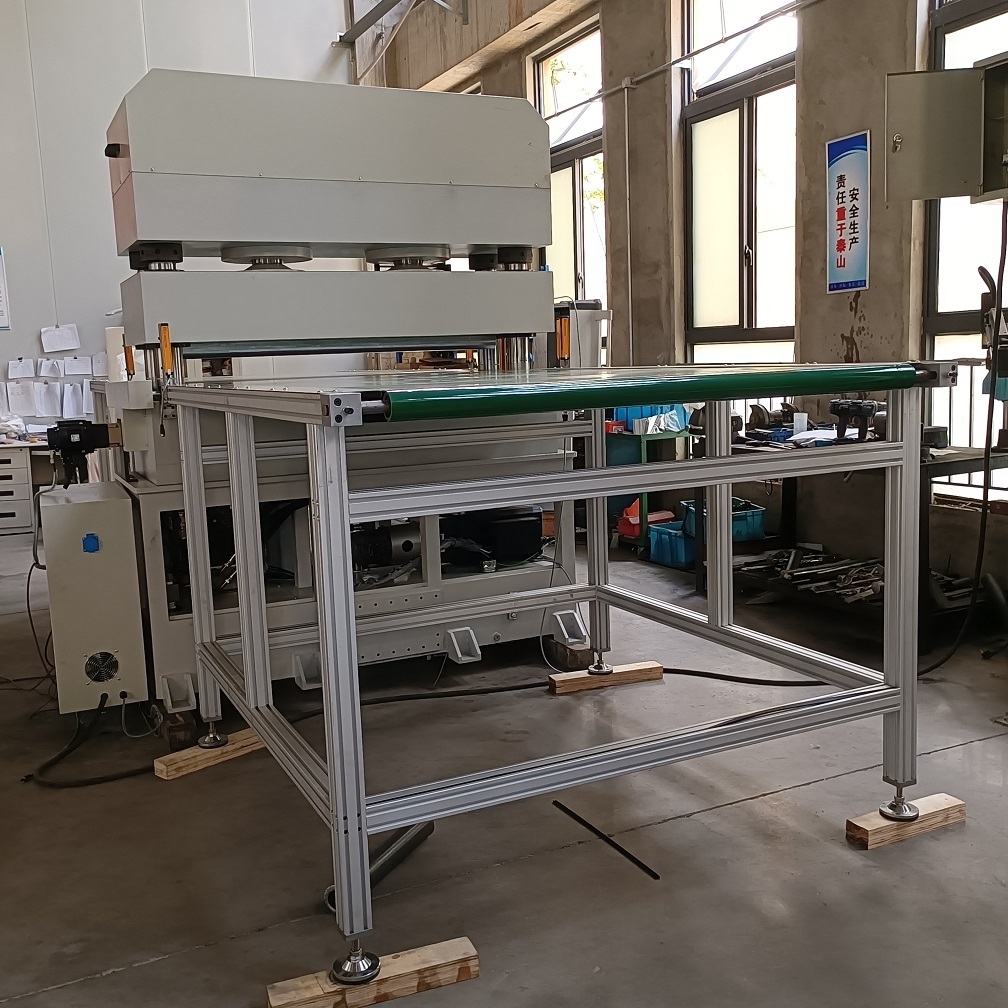

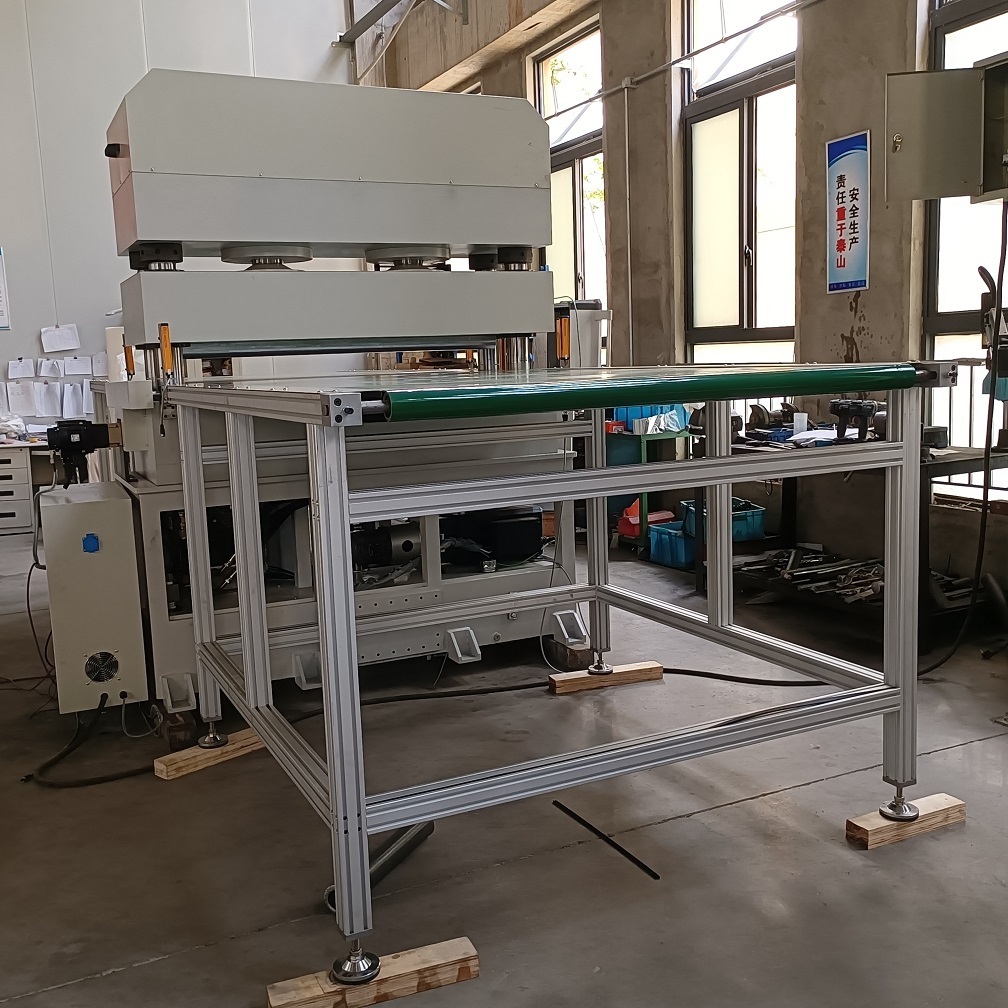

hydraulic die cutting machine

This

hydraulic die cutting machine

is mainly suitable for die cutting single or multiple layers of nonmetal rolled materials by die cutter. It is widly used in many industries, such as:

- Automotive interior

-

Sheet material industry supplies

-

Floor mats

- Abrasives, abrasive paper

-

L

eather and leathergoods – shoe uppers, wallets, purses, belts

- Lampshades – fabric or plastic, with or without cut outs

- Clothing – components for hats, ties, collars, shoulder pads

- Cork gaskets and mats

- F ilters for machinery, breathing apparatus and the printing and packaging industry

- F oam and sponge – gaskets, packaging, consumer products

- Footwear components – shoes, insoles, insole socks, uppers, straps

- P lastics – PVC binders, lampshades, stationery products, gifts, novelties, gaskets

-

R

ubber – gaskets, seals, washers

Product Description

Usage & Features

1. Automatic Cutting Machine

is applicable to continuous and large-batch cutting of nonmetal materials such as fabric leather, carpet, rubber, film, foam and cloth etc. in large-scale factories by die cutter.

2. Use PLC computer touch screen to control procedures, servo motor driver conveying system, insure feeding accurate range, with stable running speed.

3.

C

an work in

fully automatic, semi-automatic, manual mode

;

4.

The main machine is controlled by four-column guiding, double-crank balancing, four-column blocking fine adjustment mechanism and hydraulic control system, which can guarantee the speed and accuracy of die cutting machine.

5.

T

he central automatic lubrication system can guarantee the machine precision and enhance machine durability

6.

The input and output of materials are conveyed on the conveying belt, and the die cutting of materials is also automatically completed on the conveying belt.

7.

The unwinding system can be designed based on customer's requirement.

Automatic feeding flat bed table supports materials in sheet, and roll unwinding system supports materials in roll

;

8.

The device with cutting board and fixed mold to make the operation more convenient.

9. Products of special specifications can be customized.

How to choose a cutting machine:

- Material: Nonmetal material such as leather, fabric, foam, EVA, rubber gasket, etc.

- Cutting area: it depends on the material size.

- Cutting force: it depends on the blade perimeter of the die cutter.

- Feeding system: it depends on the material.

Main Technical Data(Customizable)

|

Model

|

DPMQ

|

|

|

Maximum cutting force

|

60T

|

100T

|

|

Cutting area

|

1250*800mm | 1250/1600*1200mm |

|

Motor power

|

5.5KW

|

11KW

|

| Tension Distance | 25-135mm | 25-135mm |

|

Machine weight

|

7500kg

|

10500kg

|

Hot Searches