- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Nanjing Dete

-

After After-sales Service:

-

Video technical support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE

-

Place of Origin:

-

Nanjing,Jiangsu province

-

Keywords:

-

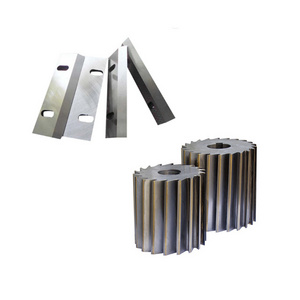

Pelletizer Hob Blade

-

Material:

-

Metal

-

Feature:

-

High Efficiency Safety Long Life

-

Application:

-

Film or other cutting

-

Package:

-

Carton Box

Quick Details

-

Marketing Type:

-

New Product

-

Core Components:

-

other

-

Type:

-

Factory direct sale

-

Brand Name:

-

Nanjing Dete

-

After After-sales Service:

-

Video technical support

-

After Warranty Service:

-

Online support

-

Certification:

-

CE

-

Place of Origin:

-

Nanjing,Jiangsu province

-

Keywords:

-

Pelletizer Hob Blade

-

Material:

-

Metal

-

Feature:

-

High Efficiency Safety Long Life

-

Application:

-

Film or other cutting

-

Package:

-

Carton Box

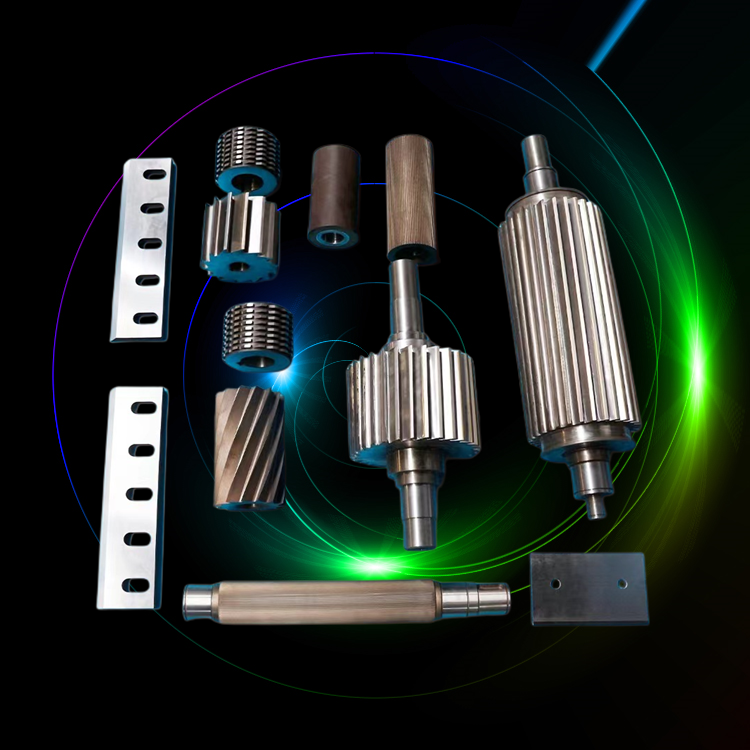

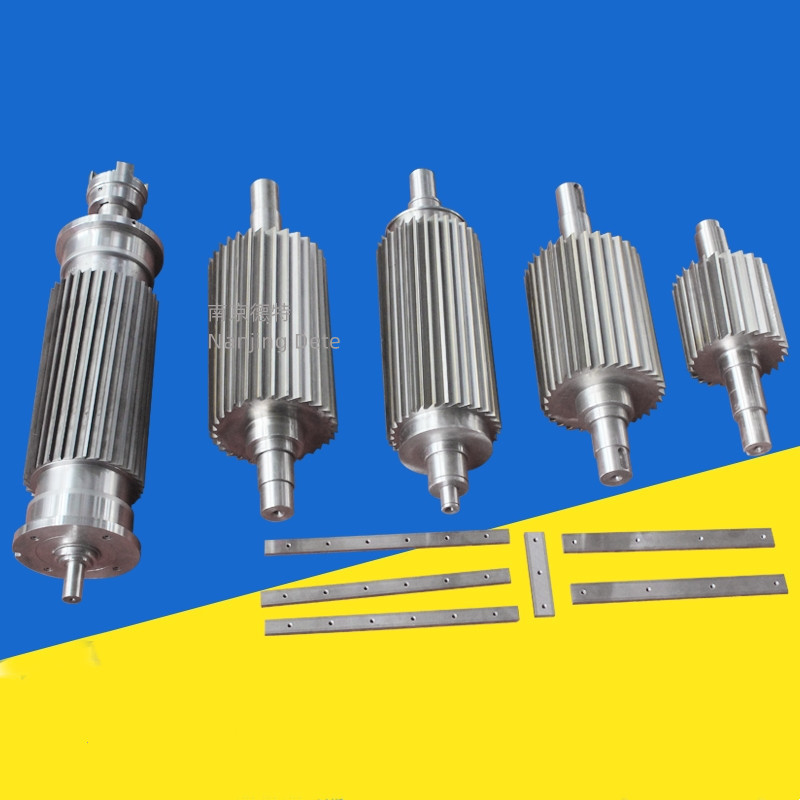

Products Description

I

ntroduction:

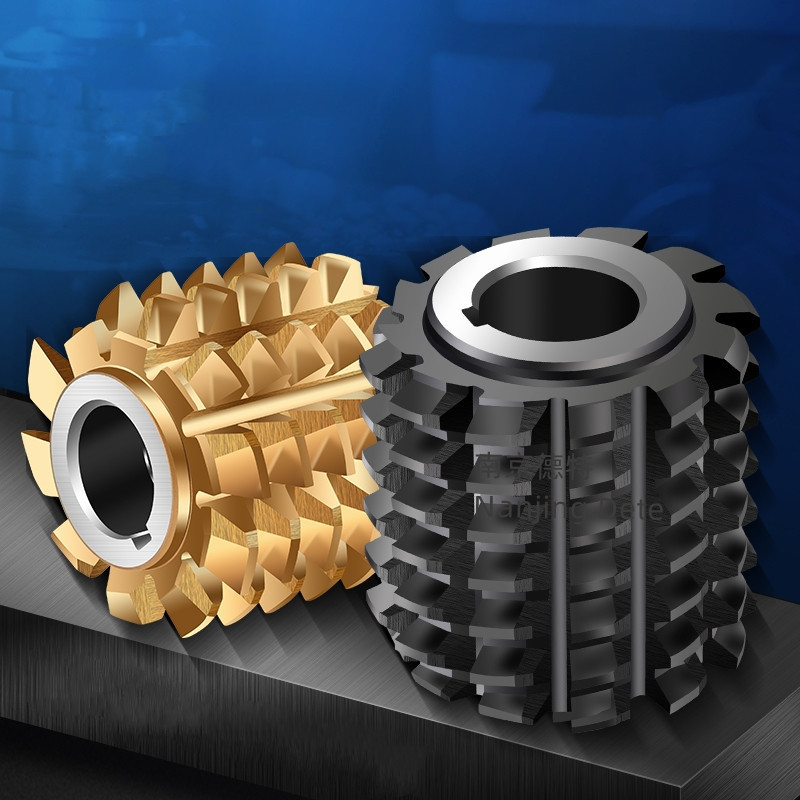

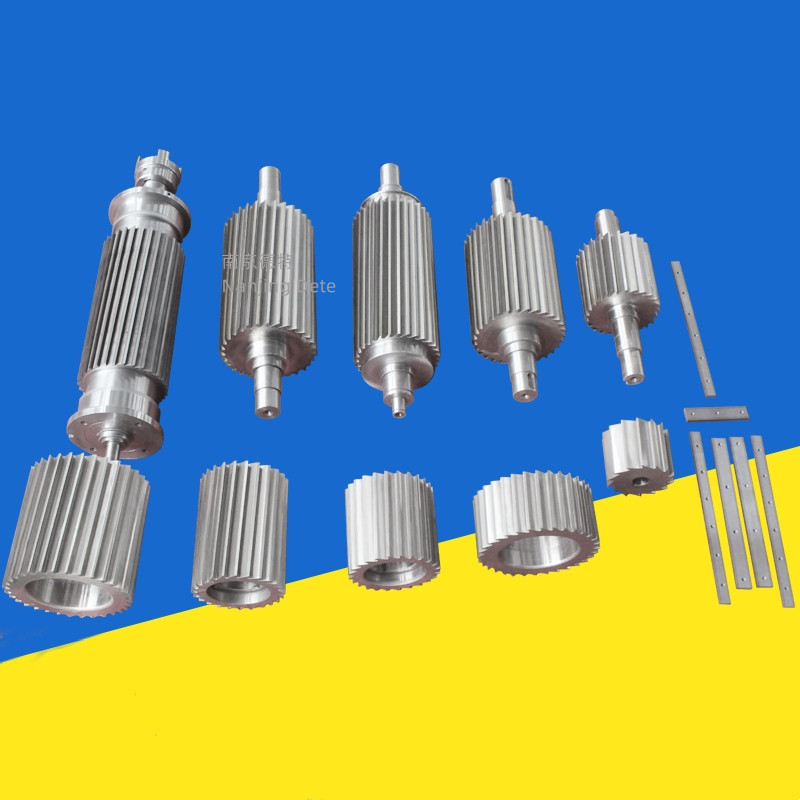

Gear machining tool with teeth arranged in helical line along cylinder or cone

Material:

The chemical composition of blade material should be selected for different needs of users and cutting different objects

Category:

Divided into gear hob, worm gear hob, non-involute spread hob and fixed hob, etc

Features:

Sharp, high hardness, good toughness

Advantages:

Good heat treatment process to achieve the blade suitable hardness and small internal stress, in the process of use without deformation

Purpose:

Used for machining cylindrical gear, worm gear and other cylindrical gear with teeth according to the spreading method

Product details

Category:

Divided into gear hob, worm gear hob, non-involute spread hob and fixed hob, etc Features: Sharp, high hardness, good toughness

Advantages:

Good heat treatment process to achieve the blade suitable hardness and small internal stress, in the process

of use without deformation Purpose: Used for machining cylindrical gear, worm gear and other cylindrical gear with teeth according to the spreading method

of use without deformation Purpose: Used for machining cylindrical gear, worm gear and other cylindrical gear with teeth according to the spreading method

Manufacturing Technique

Customized requirements

: Standard blades only need to provide dimensions, and non-standard blades can be customized for production only by providing the length, width, thickness, hole size and eye distance of the blade if drawings and samples cannot be provided. From the beginning of cutting, we select the required materials in strict accordance with customer requirements. Every link from forging, roughing, heat treatment, finishing to delivery, etc., will be produced in strict accordance with technical requirements to ensure that customers can use qualified and quality-assured blades. The company has rich experience in the control of blade heat treatment hardness. Customers only need to inform the material of the product to be crushed, and we can recommend the most suitable blade hardness to ensure that the blade achieves the best state in terms of toughness and wear resistance at the same time.

Production Process

Production Process

◆1. Blanking---choose materials according to customer requirements.

◆2. Forging--Forging is mainly to increase the density of the material.

◆3. Annealing-to lower the temperature for processing.

◆4. Finishing-mainly processing the material into shape.

◆5.Inspection---inspect whether the product is consistent with the drawing sample.

◆6. Quenching-improve the corresponding hardness of the molded product and material.

◆7. Annealing--In order to increase the wear resistance of the product, it must be annealed for a long time.

◆8. Quenching and tempering-mainly the parallelism of quenched and tempered products to facilitate processing.

◆9. Coarse grinding-rough grinding of each surface of the product.

◆10. Precision grinding-super precision grinding, mirror grinding, improve the accuracy and parallelism of the product.

◆11. Inspection-Let unqualified products refuse to flow into the market.

◆12. Packing--different packing according to different products.

Hot Searches