- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Tungsten plated sucker rod

-

Advantage:

-

Anti-Corrosion & Anti-Abrasion

-

Grade:

-

C,K,D,KD,HL,HY

-

Size:

-

5/8",3/4",7/8",1",1 1/8"

-

Joint type:

-

T type joint

-

Length:

-

25-30ft

-

Standard:

-

API 11B,

-

Color:

-

Black

-

MOQ:

-

1

-

Usage:

-

Oilfield

Quick Details

-

Weight (KG):

-

100

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SJ

-

Product name:

-

Tungsten plated sucker rod

-

Advantage:

-

Anti-Corrosion & Anti-Abrasion

-

Grade:

-

C,K,D,KD,HL,HY

-

Size:

-

5/8",3/4",7/8",1",1 1/8"

-

Joint type:

-

T type joint

-

Length:

-

25-30ft

-

Standard:

-

API 11B,

-

Color:

-

Black

-

MOQ:

-

1

-

Usage:

-

Oilfield

Shengji Anti-Corrosion & Anti-Abrasion API 11B Oil Well Coated Sucker Rod

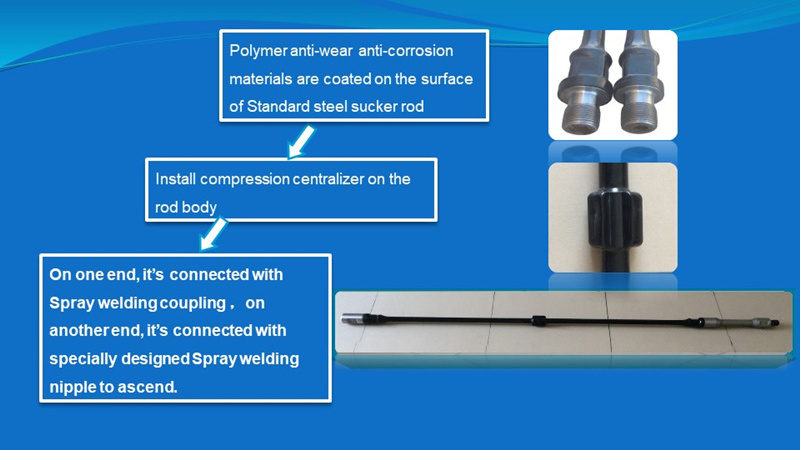

Shengji is the leading manufacturer of coated sucker rod in China,In order to improve the anti-corrosion and wear resistant performance of sucker rod, on the basis of Canada advanced liner tubing technology, Shengji Company developed the anti-corrosion and wear-resistant sucker rod production line. This product is mainly used in oil well with serious corrosion and eccentric wear problem. It is the ideal matching products of liner tubing. To the oil well that use the ordinary tubing, we add the centralizer on the rod body to improve the service life of sucker rod and tubing. The cladding layer is on the surface of the rod. New and used rod all avaibable. Overall coated polymer materials is the most effective anticorrosion and wear-resistant technology. Smooth surface, low friction coefficient with steel, it helps to reduce load of pumping unit and it has energy saving effect. Shengji coated sucker rod already applied for a patent.

1. Base on the technology of weatherford.

2. New and used rod all avaibable.

3. Anti-scaling.

4. Anti-corrosion.

1.Sucker rod size

| SN | Normal size in(mm) | Dia. of coated rod (mm) | Wrench section width (mm) | Wrench section Length (mm) | OD of Male thread step (mm) | Nipple neck length of ascension(mm) |

| 1 | 5/8(16) | 19 | 27 | 28 | 37 | 127 |

| 2 | 3/4(19) | 22 | 29 | 28 | 43 | 127 |

| 3 | 7/8(22) | 25 | 29 | 28 | 45 | 127 |

| 4 | 1(25) | 28 | 39 | 28 | 55 | 127 |

| 5 | 1 1/8(29) | 32 | 43 | 37 | 60 | 127 |

2.Coated Layer Performance

| SN | Item | Performance index | Execution Standard |

| 1 | Density/ g/cm 3 | 1.1 | GB/T1033 |

| 2 | Vicat Softening Temperature / ℃ | ≥180 | GB/T1633 |

| 3 | Tensile Yield Strength/ MPa | ≥28 | GB/T8804.3 |

| 4 | Elongation at Break Rate/ % | ≥150 | GB/T8804.3 |

| 5 | Shore Hardness/ HD | ≥80 | GB/T2411 |

|

6 |

Mortar wear rate/ mg/h | ≤3.5 | Appendix |

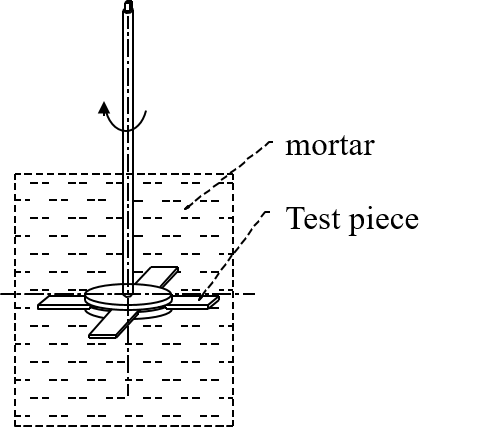

Wear resistant performance test

1. Test method

|

Use no.12 brown fused alumina sand and make mortar of sand and water with ratio of 3:1. Test-piece should be buried in mortar and it rotates with the speed of 1000r/min. After 24 hours, take out the test-piece, clean it and weigh it . Make comparison of the losses of weight. |

|

2. Wear resistant test

A. Mortar wear rate test

according to test method that specified in SINOPEC standard Q/SH1020-2011. the period of wear test is 24 hours. The data of wear in the table below:

| Item | Lined material | Coated material 1# | Coated material 2# | Coated material 3# |

| Weight before wear(g1) | 1.209 | 1.216 | 1.465 | 1.358 |

| Weight after wear(g2) | 0.7628 | 0.9477 | 1.1945 | 1.0894 |

| actual weight(g3) | 0.7626 | 0.9362 | 1.18 | 1.0761 |

| wear rate(g3-g1)/g1*100% | 37% | 23% | 19.80% | 20.80% |

Conclusion: the Mortar wear rate is higher about 15% than Ultra high molecular weight material.

B. Wear with tubing test

The test result is in the table below:

| SN | Name | Dimension before wear(mm) | Dimension after wear(mm) | abrasion loss (mm) | abrasion loss (mm/h) | coefficient of friction | |

| Group 1 | 1 | J55 tubing (Wall thickness) | 5.2 | 4.79 | 0.41 | 0.101 | 0.123 |

| Phosphating coupling(Dia.) | 41.2 | 40.45 | 0.75 | 0.1875 | |||

| 2 | J55 tubing (Wall thickness) | 4.83 | 4.73 | 0.1 | 0.025 | 0.229 | |

| Coated coupling(Dia) | 49.1 | 48.9 | 0.2 | 0.05 | |||

| Group 2 | 1 | Liner plastic tube (Wall thickness) | 4.7 | 4.45 | 0.25 | 0.056 | 0.18 |

| Phosphating coupling(Dia.) | 41.23 | 41.19 | 0.04 | 0.009 | |||

| 2 | Liner plastic tube (Wall thickness) | 4.5 | 4.28 | 0.22 | 0.049 | 0.26 | |

| Coated coupling(Dia) | 49.02 | 49 | 0 | 0 | |||

conclusion:Wear with J55 tubing, the abrasion loss of coated coupling is 1/3 of phosphating coupling. The abrasion loss of relevant tubing is 1/6. Wear with liner tubing, the abrasion loss is very small, the coated coupling is nearly zero.

C.Binding Force Test

|

Method: take length of 20mm coated rod and put on test fixture to take experiment on pressure-testing machine. |

|

|

Test result: average out-pressure is 0.24KN and the binding force bigger than0.20Mpa. |

D. Anti-corrosion T est

|

Soak coating material separately in liquor of hydrochloric acid, sulfuric acid, nitric acid and sodium hydroxide at the temperature of 60 ℃ for five hours, then take out to inspect the degree of corrosion. The result following by 18.53 , 17.61 , 23.23 , 14.11g/m 2 . |

E.Low Temperature Experiment

|

Method Take out and observe the cladding layer if there is fracture after freezing coated rod at the temperature of -30 ℃ in low temperature freezer. |

|

|

Test result: no fracture |