- Product Details

- {{item.text}}

Quick Details

-

Ejector Force(kN):

-

20 kN

-

Theoretical Shot Volume(cm³):

-

85 cm³

-

Injection Rate (g/s):

-

72 g/s

-

Injection Weight (g):

-

75 g

-

Screw diameter (mm):

-

30 mm

-

Weight (KG):

-

26000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

265 mm

-

Model Number:

-

BJ50-S6/V6

-

Brand Name:

-

powerjet

-

Power (kW):

-

3.5 kW

-

Opening Stroke:

-

265 MM

-

Injection Rate:

-

94 G/SEC

-

Power(W):

-

11KW

-

Injection Weight:

-

80 G

-

Product name:

-

Small Plastic Injection Molding Machine

-

Keyword:

-

Plastic Machinery Equipment

-

Automatic:

-

Powerjet

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE, ISO

Quick Details

-

Distance between Tie Bars(Width)(mm):

-

575mm

-

Distance between Tie Bars(Height)(mm):

-

575mm

-

Ejector Stroke(mm):

-

70 mm

-

Ejector Force(kN):

-

20 kN

-

Theoretical Shot Volume(cm³):

-

85 cm³

-

Injection Rate (g/s):

-

72 g/s

-

Injection Weight (g):

-

75 g

-

Screw diameter (mm):

-

30 mm

-

Weight (KG):

-

26000 kg

-

Place of Origin:

-

Guangdong, China

-

Open Stroke(mm):

-

265 mm

-

Model Number:

-

BJ50-S6/V6

-

Brand Name:

-

powerjet

-

Power (kW):

-

3.5 kW

-

Opening Stroke:

-

265 MM

-

Injection Rate:

-

94 G/SEC

-

Power(W):

-

11KW

-

Injection Weight:

-

80 G

-

Product name:

-

Small Plastic Injection Molding Machine

-

Keyword:

-

Plastic Machinery Equipment

-

Automatic:

-

Powerjet

-

After-sales Service Provided:

-

Video technical support

-

Certification:

-

CE, ISO

Products Description

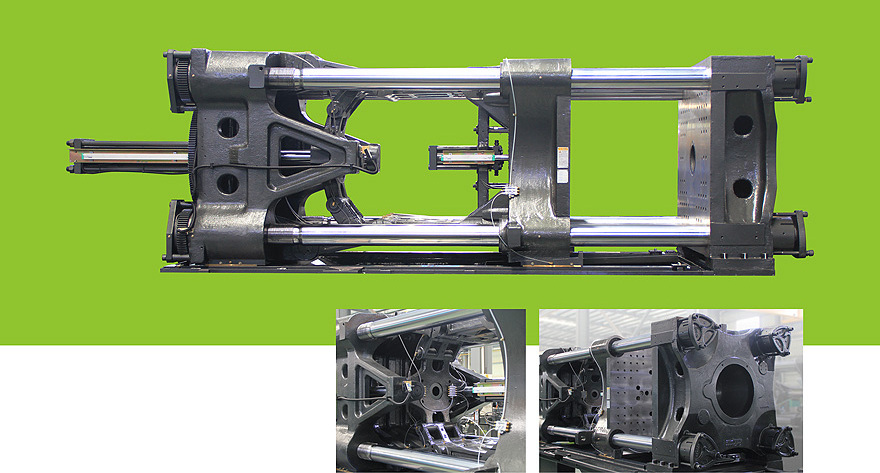

CLAMPING UNIT

Center-pressing toggle structure design, high clamping force, high rigidity, low deformation, production fast and stable.T-slot platen, convenient and fast mould change.

S6 Servo motor

With the adoption of servo control system, the injection pressure & speed 15 under closed loop controlled, and the stability and repeatability can be achieved.

V6 Variable Pump

Perfect combination between computer and high efficient proportional plunger variable pump saves electricity by 25%-50%. The economic efficiency is high.

Comparing with the hydraulic machine, S6 series can save more 50% of the power. Comparing with full electrical machine, energy saving is more obviously seen during pressure hold & cooling stage.

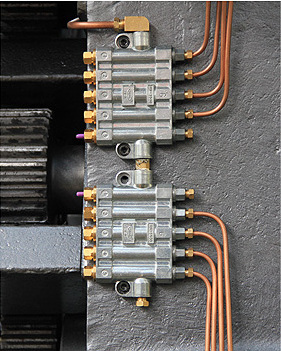

Imported top grade hydraulic components

High precision oil filter and full flow bypass oil

filter

Screw is

driven by low speed & big torque hydraulic motor

Finite element analysis is used on the structure of

mould plates So that the structure of mould plate

is more logical,stronger and higher fatigue resistance.

Automatic dosing lubrication system guarantees mould clamping mechanism to be more stable and reliable.

High precision electric meter is used to

control position. The control precision is

+0.1mm.

Mechanical and double electric interlock

protection devices guarantee the safety

of the operators. (Machine above BJ400 is equipped with hydraulic safety device. )

Wear resistant hard chromium plated tie

bar is featured

with high-tensile and high

strength.

Hydraulic motor with centering gear mould

adjusting system makes mould adjusting

system to be better.

Product Paramenters

|

DESCRIPTION

|

|

UNIT

|

BJ50-S6

|

|

|

CLAMPING UNIT

|

Clamping force

|

KN

|

500

|

|

|

|

Opening stroke

|

mm

|

265

|

|

|

|

Max.datlight

|

mm

|

575

|

|

|

|

Platen size

|

mm

|

480*480

|

|

|

|

Space between bars

|

mm

|

340*315

|

|

|

|

Max.mold height

|

mm

|

310

|

|

|

|

Min.mold height

|

mm

|

110

|

|

|

|

Ejector stroke

|

mm

|

70

|

|

|

|

Ejector force

|

KN

|

20

|

|

|

INJECTION UNIT

|

Screw diameter

|

mm

|

30

|

|

|

|

Screw L/D Ratio

|

L/D

|

18.3

|

|

|

|

Injection Pressure

|

MPa

|

193

|

|

|

|

Shot volume

|

cm3

|

85

|

|

|

|

Screw stroke

|

mm

|

120

|

|

|

|

Screw speed

|

rpm

|

206

|

|

|

POWER UNIT

|

Hydraulic system Pressure

|

MPa

|

17.5

|

|

|

|

Pump motor power

|

KW

|

7.5/11

|

|

|

|

Heater power

|

kW

|

3.5

|

|

Hot Searches