- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Power (kW):

-

6.5

-

Weight (KG):

-

1500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Edge banding machine name:

-

GoodCut fully automatic edge banding machine for door

-

Application:

-

Kitchen cabinet, wardrobe, office table

-

Application material:

-

woodworking plywood mdf board making

-

Material:

-

PVC, Acrylic, Veneer

-

Model:

-

Full automatic, Semi automatic

-

Standard Functions:

-

Gluing, End cutting, Fine trimming, Scraping, Buffing

-

Optional Functions:

-

Premilling,Grooving,Rough trimming

-

Feed speed:

-

12-20m/min

-

Workpiece:

-

10-60mm

-

Working methods:

-

Automatic Hot Press

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

GoodCut

-

Voltage:

-

220V/380V/customized

-

Dimension(L*W*H):

-

4000*900*1600mm

-

Power (kW):

-

6.5

-

Weight (KG):

-

1500 kg

-

Panel Feed Speed(m/min):

-

20m/min

-

Edge banding machine name:

-

GoodCut fully automatic edge banding machine for door

-

Application:

-

Kitchen cabinet, wardrobe, office table

-

Application material:

-

woodworking plywood mdf board making

-

Material:

-

PVC, Acrylic, Veneer

-

Model:

-

Full automatic, Semi automatic

-

Standard Functions:

-

Gluing, End cutting, Fine trimming, Scraping, Buffing

-

Optional Functions:

-

Premilling,Grooving,Rough trimming

-

Feed speed:

-

12-20m/min

-

Workpiece:

-

10-60mm

-

Working methods:

-

Automatic Hot Press

GoodCut fully automatic edge banding machine for door

This machine is suitable for straight edge banding of solid wood board, fiberboard, particle board and other plate workpieces. The edge banding materials can be solid wood skin, melamine, PVC, veneer, etc. The machine adopts high-quality motors, imported electrical components, serialized products, diversified customer choices, and features high accuracy and high efficiency.

Parameter:

|

Model

|

Parameters

|

|

Keywords

|

Fully Automatic Edge Banding Machine/Premilling Edge Banding Machine

|

|

Panel Length

|

Min.120mm(pvc)

|

|

Panel Width

|

Min.80mm

|

|

Panel Thickness

|

12-55mm

|

|

Edge Thickness

|

0.4-3mm

|

|

Feeding Speed

|

13m/min

|

|

Working Pressure

|

0.6mpa

|

|

Net Weight

|

1500kg

|

|

Total Power

|

5.49kw

|

|

Overall size

|

3155x1110x1300mm

|

|

Packing Size

|

2720x760x1300mm

|

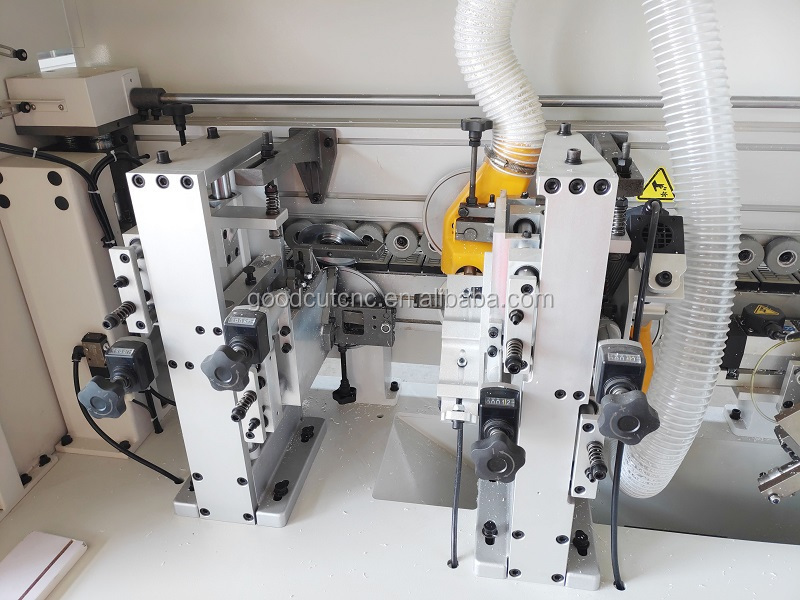

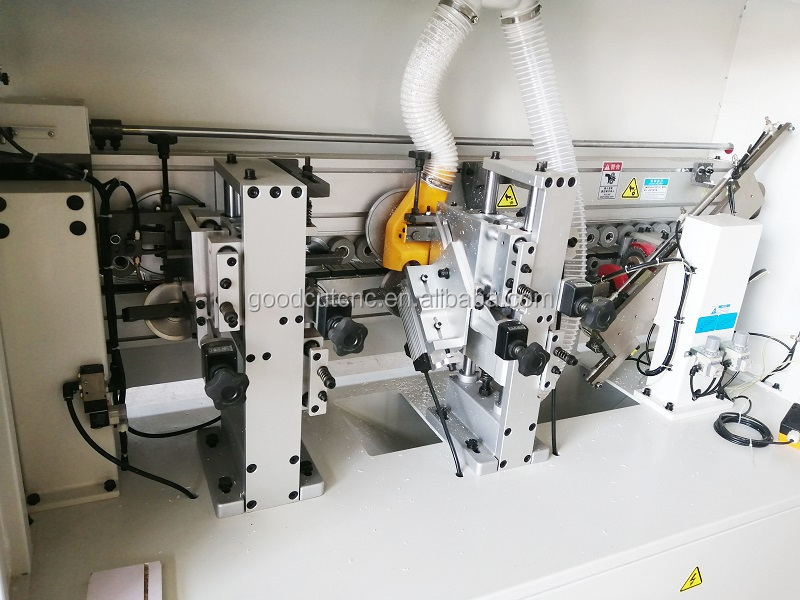

1.Gluing system:

Special gluing system, heating fast, gluing wheels processing precisely, uniformly and perfectly .

2. Pressure system:

Processing work is done by two sets of wheels. Coincident working of high precision large pressure wheel and gluing wheel ensure pressure effect. Small pressure wheel contains up and down cone wheel and a straight wheel. Up and down conewheel ensure joint of edgeband and workpiece.

3. Edgeband cutting system:

Strong cutting cylinder with a independent voltage regulating system which guarantee cutting speed and cooperating with high hardness cutter ensure the powerful cutting.

4.End cutting system:

Precision linear guide movement, automatic profiling tracking and high frequency high speed motor structure ensure the smooth cut surface .

5. Rough trimming system

Flat blades are installed in the up and down two independent high frequency motor , flat blades cutting reduce the tool marks caused by the following circular arc trimming.

6. Fine trimming system:

Up and down fine trimming tool is installed on two high frequency motor with circular arc cutters, very convenient and accurate to operate.

7.Scraping system:

It is used for less than or equal to 3mm PVC or ABS edgeband,unpowdered scraping system is based on high stiffness structure. Two precise profile wheels each group ensure the accuracy of cutting point.

8. Buffing components:

Two independent motor with buffing wheels is used for cleaning and buffing after edging.

Simple design, very easy to operate.

Features :

1.This edge bander is ideal for building an automatic production line. Stability and controlled ability are the most important factors for an equipment to be part of production line.

2.Pre-milling equipment with double trim-blades works on the waved effect that is caused by precise saw.

3.The glue mechanism adopts a special structure to gelatinize the plates and coating materials uniformly, ensure a more solid conglutination.

4.End-trimming mechanism through a precise guide track movement, adopt automatic tracking and high-frequency motor fast cutting structure to ensure the cutting surface smoothly.

5.Rough &Fine Trimming unit, with two individual high frequency motors, trim the exceeding edge on the top and bottom side of the panel, ensure the top and bottom side of the edge smooth and even.

6.Scraping unit for a perfect finishing of the applied edge.

7.The buffing device adopt the board processed by cotton polishing wheel, by end-polishing to make a more smooth surface.

8.Grooving is a optional function for edge banding machine. It's used to slot out one groove on panel to install glass, back panel etc.

Samples&Application:

1.The machine is suitable for linear sealing side of plank artifacts of solid board,fiberboard,particleboard,ect...Edge banding material artical available solid wood,PVC,melamin,thin veneer and so on.

2. Adopt imported motor and high quality electrical compents.

3. Product serialization.diversification of the customer to choose.

4.High precision and high efficiency.

About US:

Jinan GoodCut CNC Machinery Co., Ltd.

The meaning of “GoodCut” brand: Good Quality, Good Price, Good Service

Good Quality

1. 15 engineers with more than 10 years rich working experience, manufacture high precision machines;

2.Three-day 72-hour testing machine inspection, after confirming that the machine has no quality problems, then it will be shipped;

3. 4 QC staffs do strict evaluations on in-coming inspections, in-process inspections and final inspections.

Good Price

1. GoodCut manufactures about 50 sets of machines per month, with a large sales volume. We have long-term cooperation with parts suppliers, can get advantageous prices of parts, so that the price of machine is very competitive;

2. GoodCut aims to develop long-term cooperation with new and regular customers, and to give customers the best prices with the most sincere attitude.

Good Service

1. English manual and video f or machine using and maintaining , explaining the operation steps in detail;

2. Professional after-sales service staffs, providing 24-hour online service;

3. Provide free technical training and factory field operation teaching.

Jinan GoodCut CNC Machinery Co.,Ltd

Website:www.goodcutcnc.com

www.goodcutcnc.com

Linna Du

Mobile/WhatsApp/WeChat:008617615806860