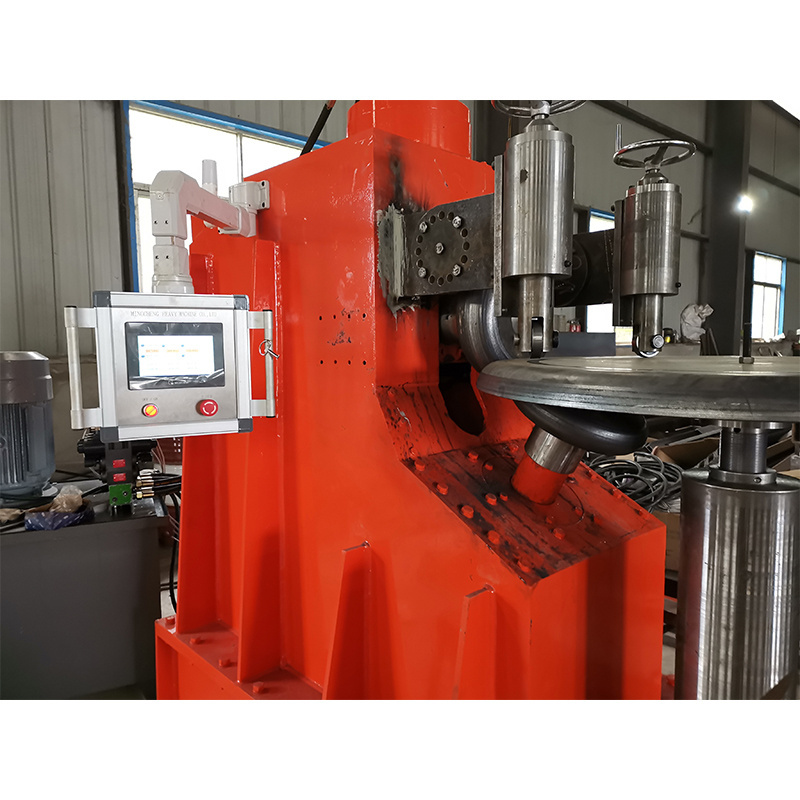

The structure of the machine is symmetric between the main drive wheel and the passive wheel. Then the workpiece welding or fixed

on the turntable, the wheel up and down the central symmetry position through the oil cylinder lifting movement, balance and get

the rotation rotation, through the output of the speed reducer and the roller mesh, 360 ° rotating implementation artifacts. When

the roller pressure exceeds the yield limit of the material, then make the deformation of the rolled material, so as to achieve rolling diameter size.

- Product Details

- {{item.text}}

Quick Details

-

Product name::

-

dished end flanging machine

-

Power::

-

hydraulic

-

Max diameters::

-

≤41000 mm

-

Max thickness::

-

4mm

-

Dish ends kinds::

-

ellipse, dish, sphericity, etc

-

Speed::

-

5m/min

-

Application:

-

food ,Beer can,oil tank,beverage can ect.

-

Voltage:

-

380V/50HZ/3phase 220V/60HZ/3phase

-

Yield limit::

-

245 MPa

-

Main motor power::

-

3.7 KW

Quick Details

-

Place of Origin:

-

Liaoning, China

-

Brand Name:

-

MC

-

Weight (KG):

-

300

-

Product name::

-

dished end flanging machine

-

Power::

-

hydraulic

-

Max diameters::

-

≤41000 mm

-

Max thickness::

-

4mm

-

Dish ends kinds::

-

ellipse, dish, sphericity, etc

-

Speed::

-

5m/min

-

Application:

-

food ,Beer can,oil tank,beverage can ect.

-

Voltage:

-

380V/50HZ/3phase 220V/60HZ/3phase

-

Yield limit::

-

245 MPa

-

Main motor power::

-

3.7 KW

Contacts: Mark Liu

Tel: +86-411-82766928

Fax: +86-411-39015062

Email: Liu@mingchenggroup.com

Mob/Whatsapp: +86 133 9411 0095

Products Description

Other cutting machine recommendations

Product details

Conical head forming machine (edge grinding machine) is divided into manual head forming machine (edge grinding machine) and automatic head forming machine (edge grinding machine). The edge shape is beautiful, the quality is reliable, the production efficiency is high, the operation is convenient, and the equipment characteristics are easy to master. It not only improves production efficiency and ensures high-quality production, but also improves the operating environment.

Flanging principle

Product Paramenters

|

Modle

|

Max. thickness(mm)

|

Max.length(mm)

|

Advantages

|

Voltage(V)

|

|

MC0520

|

5

|

200

|

the dished end have smoothly surface, less wheel marks, good roundness, Less thinning and ,high productivity

|

380V/50HZ

220V/60HZ |

|

MC0540

|

5

|

400

|

|

|

|

MC0560

|

5

|

600

|

|

|

|

MC0640

|

6

|

400

|

|

|

|

MC0660

|

6

|

600

|

|

|

|

MC0680

|

6

|

800

|

|

|

|

MC07200

|

7

|

2000

|

|

|

|

MC07400

|

7

|

4000

|

|

|

|

MC08400

|

8

|

4000

|

|

|

|

MC08600

|

8

|

6000

|

|

|

The dished end machine model can be customized, if you need, you can contact us at any time

Recommend Products

Hot Searches