- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

changyi

-

Dimension(L*W*H):

-

custom

-

Description:

-

Agitation Barrel

-

Effective Volume ::

-

0.26-30m3

-

Power Range ::

-

1.1-22kw

-

Processed Materials ::

-

Various metal and nonmetal materials

-

Application ::

-

materials mixing in ore processing plant, building materials, road

-

Certificate:

-

CE,ISO9001:2008

-

Gurantee time:

-

1 year excluding wearing parts

-

Voltage:

-

customized Agitator tank

-

Another description:

-

Mining Stirriing barrel

-

Usage:

-

Leaching Equipment

Quick Details

-

Weight (KG):

-

500

-

Application:

-

mining

-

Production Capacity:

-

1000set/mouth

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

changyi

-

Dimension(L*W*H):

-

custom

-

Description:

-

Agitation Barrel

-

Effective Volume ::

-

0.26-30m3

-

Power Range ::

-

1.1-22kw

-

Processed Materials ::

-

Various metal and nonmetal materials

-

Application ::

-

materials mixing in ore processing plant, building materials, road

-

Certificate:

-

CE,ISO9001:2008

-

Gurantee time:

-

1 year excluding wearing parts

-

Voltage:

-

customized Agitator tank

-

Another description:

-

Mining Stirriing barrel

-

Usage:

-

Leaching Equipment

Product Description

Mineral Agitation Barrel

The mineral agitation barrel is driven by the electric motor to rotate the impeller, and the upper and lower circulation stirring

is carried out in the tank body, so that the medicine and the slurry are well mixed uniformly, and the necessary reaction

equipment for increasing the reaction time of the medicine is enhanced. It is mainly used for better beneficiation operation

before flotation.

is carried out in the tank body, so that the medicine and the slurry are well mixed uniformly, and the necessary reaction

equipment for increasing the reaction time of the medicine is enhanced. It is mainly used for better beneficiation operation

before flotation.

Agitation Tank Introduction

Agitation tank is the necessary equipment to extend the medicament reaction time and strengthen the drug reaction quality. It is mainly used to mix pulp before flotation in beneficiation processing and make potions and pulp fully mixed. Also it can be used for roiling mixing or dilution mixing in chemical industry. It is installed before the flotation machine and makes the reagent and the ore pulp to be fully mixed. This machine is suitable for mixing the ore pulp whose density is lower than 3.5 and the flotation reagents whose density is lower than 30%.

Agitation Tank Working Principle

Agitation tank for chemical reagent for chemical reagent adopts barrel shaped radiation circular spiral impeller for mixing operation by mechanical stirring method. The motor drives V- belt transmission device which drives the impeller. Reagents mix evenly under the rotation of impeller preparing for next step that mix the ore slurry and reagents. Agitation tank for chemical reagent is used for reagents preparation before floatation.

Widely Application

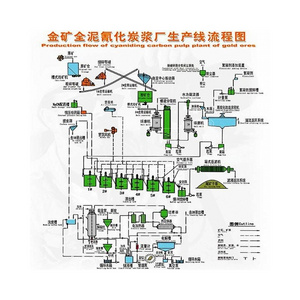

Agitation tank is mainly applied in slurry stirring before floatation, chemical and construction industry, cyanide chemical plant, sewage treatment plant, and coal plant etc.

Gold CIL Plant---Process Description

1. After the crushing and grinding stage, add 9 step-arranged high-efficiency cyanidation leaching tanks into the pulp. Gold pulp cyanidation is carried on the first two leaching tanks, countercurrent adsorption operation is carried on the last six or seven leaching tanks. Compared with gold CIP process and other traditional gold extraction processes, gold CIL process greatly shortens the cyaniding time, reduces the capital backlog in the gold retention stage. Taking the gold cyanidation plant with processing capacity of 100000 tons and gold grade of 7.5 g/t as an example, gold CIL process can save the investment cost of $486000 than the CIP process, reduce the capital backlog of $201700, save and recycle capital of $675100 in advance excluding the cost of activated carbon.

2. In the adding activated carbon step, add the coconut shell activated carbon (small hole, high activity, wear-resisting and renewable) specially selected by gaoxuan mineral processing design institute into the pulp, which can dissolve and adsorb the gold and silver ions then form the gold loaded carbon according to the characteristics of gold and silver adsorption.

3. Vibrating screen and dewatering screen are the key equipment for the reverse movement of pulp and carbon. Filter press and high frequency dewatering screen developed by gaoxuan can effectively reduce the carbon wear on the surface of vibrating screen and in the process of continuous slurry pumping, and reduce the cost, facilitate the maintenance and operation.

4. gaoxuan desorption electrolysis system implements high-temperature desorption electrolysis on gold in the gold-loaded carbon through the mixed liquor of sodium cyanide and sodium hydroxide. After wood chips and other sundries are removed by washing machine, and the gold desorption is carried out by Xinhai high-temperature and high-pressure desorption method (150 degrees and 0.5Mpa), which can resolve 99% of gold within 2-6 hours.

Specification

|

Model

|

Effective volume

(m³) |

Impeller revolution

(r/min) |

Impeller dia.

(mm) |

Motor power

(kw) |

Weight

(kg) |

|

XB05

|

0.078

|

690

|

150

|

0.75

|

110

|

|

XB07

|

0.26

|

530

|

240

|

1.5

|

228

|

|

XB10

|

0.58

|

530

|

240

|

1.5

|

350

|

|

XB12

|

1.14

|

320

|

400

|

3

|

765

|

|

XB15

|

2.2

|

320

|

400

|

3

|

1360

|

|

XB20

|

5.5

|

230

|

550

|

5.5

|

1655

|

|

XB25

|

11

|

230

|

625

|

7.5

|

2766

|

|

XB30

|

19.1

|

210

|

900

|

18.5

|

4296

|

|

GBJ-10

|

0.58

|

530

|

240

|

2.2

|

548

|

|

GBJ-12

|

1.15

|

350

|

240

|

3

|

1108

|

|

GBJ-15

|

2.2

|

320

|

420

|

5.5

|

2207

|

|

GBJ-20

|

4.4

|

240

|

560

|

7.5

|

3110

|

|

GBJ-25

|

9.2

|

272

|

560

|

15

|

3939

|

|

GBJ-30

|

19.1

|

211

|

700

|

18.5

|

4613

|

|

GBJ-40

|

45

|

153

|

1000

|

30

|

9560

|

Packing & Delivery

Hot Searches