- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

1230*620*1300

-

Weight:

-

700

-

Power (kW):

-

2400W

-

Applicable Industries:

-

Plastic industry, Rubber industry

-

Product Name:

-

25T Flat vulcanizer

-

Maximum Hydraulic Pressure:

-

16Mpa

-

Working Temperature:

-

0 ℃ to 200 ℃

-

Heating Method:

-

Electric heating

-

Motor:

-

Three-phase motor

-

Display and Control:

-

±1 ℃

Quick Details

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Qunlong

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

1230*620*1300

-

Weight:

-

700

-

Power (kW):

-

2400W

-

Applicable Industries:

-

Plastic industry, Rubber industry

-

Product Name:

-

25T Flat vulcanizer

-

Maximum Hydraulic Pressure:

-

16Mpa

-

Working Temperature:

-

0 ℃ to 200 ℃

-

Heating Method:

-

Electric heating

-

Motor:

-

Three-phase motor

-

Display and Control:

-

±1 ℃

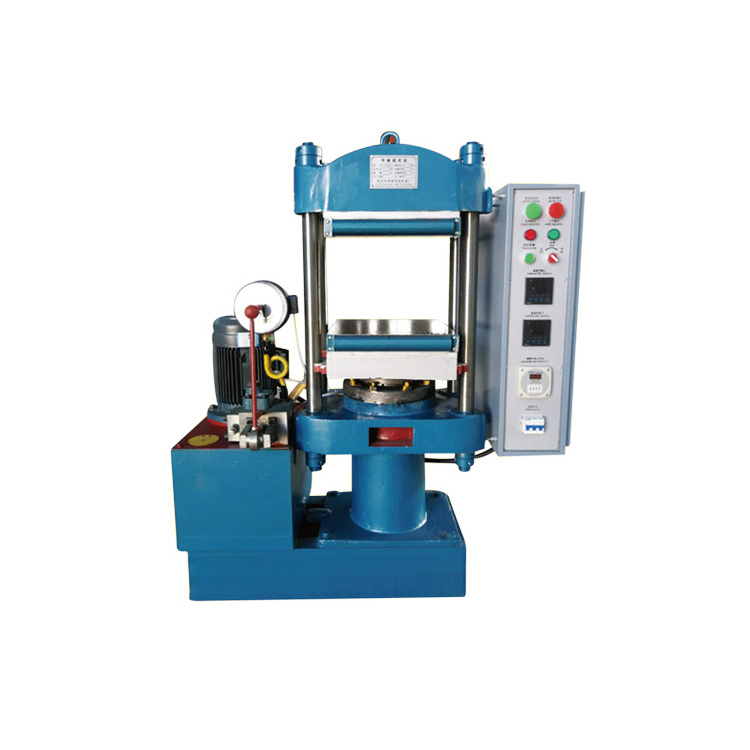

Silicone Mold Flat Vulcanizer O-ring EVA Foam Sheet Yoga Mat Shoe Sole Rubber Tile Vulcanizing Press Machine

Plate vulcanizing machine is a new type of hydraulic plate vulcanizing machine. Compared with the old model of pressure forming machine, it can obviously improve the quality of pressing parts and greatly improve the labor productivity.

This machine is suitable for vulcanization of all kinds of rubber products. It is a necessary equipment for forming and processing plastics, rubber foams, bakelite products and various thermosetting materials.

This model has the following characteristics:

1. This machine is a combination of mechanical, electrical and hydraulic technologies, with semi-automatic performance.

2. the host column and frame type two structures, the main body is bright, clean, rigid, hydraulic cylinder on the beam, mobile platform, using ductile iron, the host performance is stable, durable.

3. the hydraulic part adopts two ways, one is a single pump drive, simple structure, convenient, reliable performance, generally used in small tonnage equipment, one is a combination of double pump, speed, pressure, generally used in large tonnage equipment, hydraulic schematic diagram attached.

4. The electrical parts have the characteristics of reliable quality and accurate temperature control. The heating connection part is connected by high temperature resistant wire, which has good reliability.

5. The electric heating system adopts tubular resistance heater, which is installed in the hot plate and heated by the heating plate (customers without boiler). It is an ideal heating method with low power consumption, no glue forming, even temperature and good insulation.

6. The machine has excellent material selection, wide processing range, and various indicators can meet the standard requirements of HG/ t3034-1999, with a good price performance ratio.

Technical Parameters

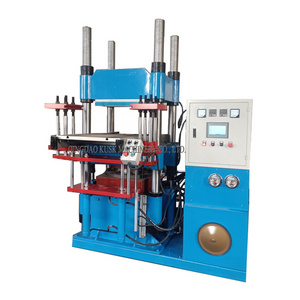

| Model | QLLHY-25T | QLLHY-50T | QLLHY-100T |

| Plate Size | 350×350mm | 400×400mm | 450×450mm |

| Working Layer | 1 layer (can be added by 1) | ||

| Plate Distance | Single layer 75-280mm (optional); Double layer 110mm | ||

| Maximum Hydraulic Pressure | 16Mpa | 16Mpa | 16Mpa |

| Cylinder Diameter | 152mm | 200mm | 285mm or 300mm |

| Maximum Temperature | 200° | ||

| Heating Method | Electric heating | ||

| Motor | Three-phase motor | ||

| Structure | Four-post type | ||

| Power(each layer of hot plate) | 2400W | 2700W | 3000W |

| Weight | About 700kg | ||

| Voltage | 380V | ||

| Size | 1230*620*1300mm | ||

| Special Requirements | Customized according to requirements | ||

| Standard Accessories | host | ||

| Optional | Heating plate 1 layer, rubber sample preparation mold, plastic sample preparation mold, automatic decompression, plastic products plus water cooling | ||

| Prepared by Customer | No. 46 Great Wall hydraulic oil 24kg or 16L/two barrels, 6 square or 8 square 3+2=5 core waterproof wire (with grounding) | ||

Structural features

This machine has two heating types of steam and electricity. It is mainly composed of the main engine, hydraulic system and electric control system. The oil tank is installed on the left side of the main engine, which is not affected by the temperature of the hot plate. The operating valve is installed on the left side of the main engine. The electric cabinet shall be separately installed on the right side of the main engine. Thus can guarantee the hot plate temperature uniformity, the hot plate temperature automatic control, the temperature control precision is high, the processing product quality is good.

Features: no pressure drop, no oil leakage, low noise, high temperature control accuracy, flexible operation.

Structure

hydraulic plate vulcanizing machine, the whole machine is divided into: host, hydraulic system, electrical control system is composed of three major parts.

1. Host part

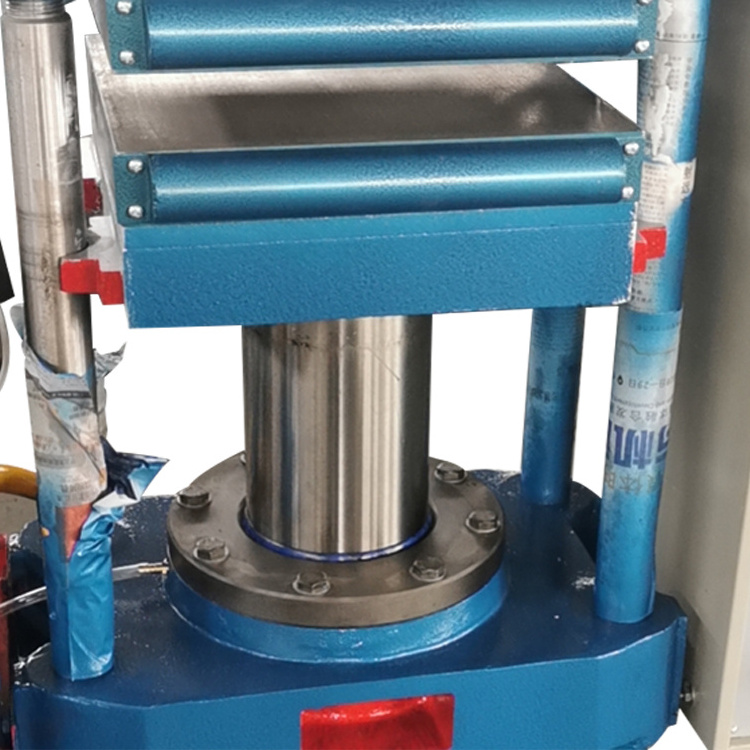

The hydraulic cylinder of the main engine is made of nodular cast iron. The whole machine has compact structure, firm and reliable, high manufacturing accuracy, good sealing performance, no oil leakage, stable working performance, good pressure maintaining performance, high production efficiency, safe operation, convenient and sensitive.

At the same time, the production of steam and heat oil vulcanizing machine.

2. Hydraulic system

Reasonable hydraulic circuit is composed of motor, gear pump or combination pump, one-way valve, overflow valve, combination pressure control valve, oil filter, liquid level meter, etc. It has the advantages of saving power, low noise, stable flow and good pressure maintaining performance.

Add 46# or 32# anti-wear hydraulic oil into the oil tank to the middle level of the liquid level gauge, raise the manual control valve, start the button, and the hydraulic system will automatically drive the plunger to complete the lifting, pressure maintaining and pressure replenishing, etc..

Note:please make sure that the hydraulic oil is clean!!!

3. Electrical control system:

electrical system principle of hydraulic plate vulcanizing machine, see electrical schematic diagram, temperature controller controls the on and off of contactor to adjust the temperature of hot plate. YXC-- 150 electric contact pressure gauge, control the working pressure and the implementation of supplementary pressure, digital time relay accurate timing, set time to, alarm die opening.

Principle

1. Principle of electrical workpiece (attached with electrical schematic diagram)

After connecting the power supply, press the start button QA, contactor KA2, intermediate relay KA1,KA2 to suck and close, the motor runs, drives the oil pump to work, closes the mold or, by YXC150 magnetic aid electric contact pressure gauge, controls the working pressure, after reaching the set pressure, connects KA3, stops working, the time relay starts timing. Due to the pressure drop caused by the flow of the plastic material in the mold after heating and pressing, when it reaches the filling pressure point, it will automatically switch on KA2 for filling pressure.

For the heating part, open the heating knob to control the temperature of the heating plate. The control instrument is in the working state, and automatically adjust and control the temperature after rising to the set temperature.

2. Working principle of hydraulic pressure

After starting the motor, the oil enters the gear pump or vane pump through the oil filter from the oil tank.

A. The gear pump will discharge the low-pressure oil to the one-way valve, and the oil will enter the cylinder through the low-pressure one-way valve to make the plunger rise rapidly. After closing the mold, the low-pressure valve will automatically close and the low-pressure oil will unload through the overflow valve.

B. The vane pump and gear pump double pump flow together, enter the oil cylinder through the high and low overflow valve, and rise rapidly. After closing the mold, the low-pressure oil is discharged through the overflow valve, while the high-pressure oil drives the plunger to reach the set pressure and stop working.