- Product Details

- {{item.text}}

Quick Details

-

Power (kW):

-

45

-

Weight (KG):

-

9000 KG

-

Name:

-

used tire retreading equipment

-

After-sales Service Provided:

-

Overseas service center available

-

Power:

-

45 KW

-

Certification:

-

CE ISO

-

Type:

-

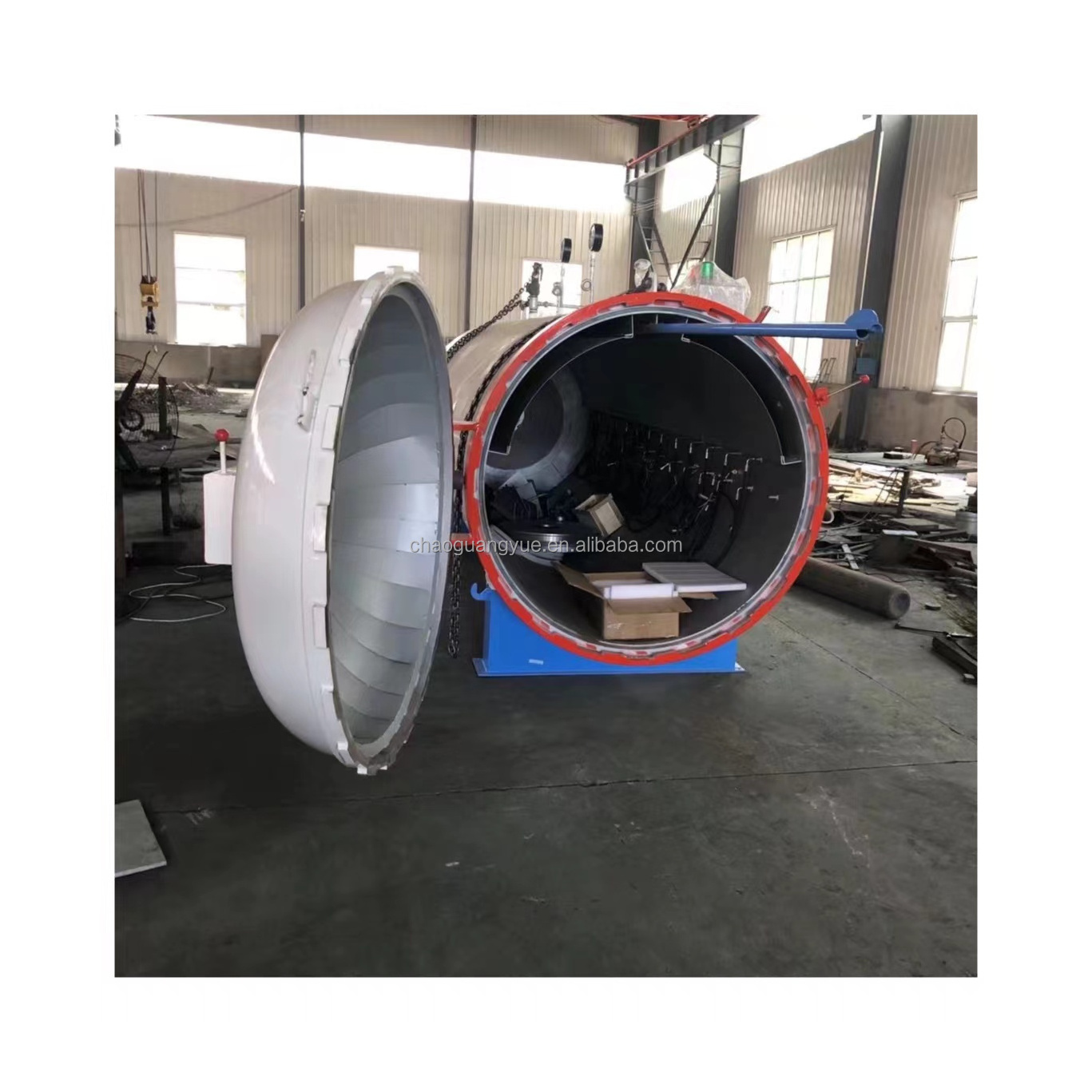

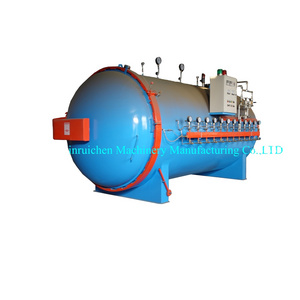

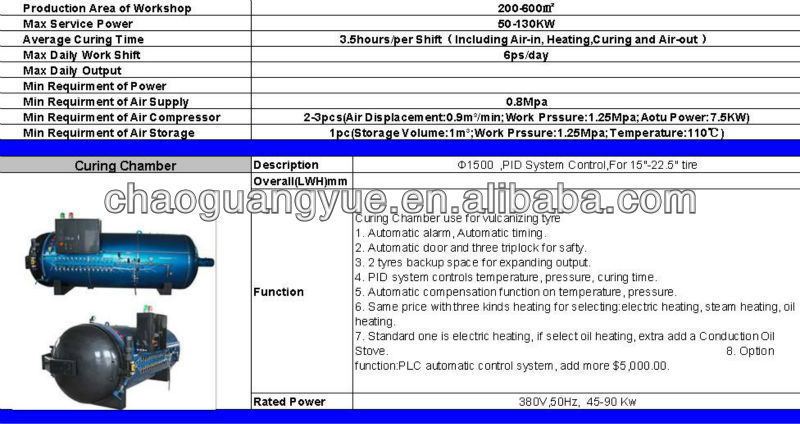

Cold Tire Retreading Machine Autoclave

-

Control system:

-

PLC

-

COLOR:

-

Custom Made

-

Advantage 1:

-

High Efficient

-

Advantage 2:

-

Enviramental

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

cgy

-

Voltage:

-

380

-

Power (kW):

-

45

-

Weight (KG):

-

9000 KG

-

Name:

-

used tire retreading equipment

-

After-sales Service Provided:

-

Overseas service center available

-

Power:

-

45 KW

-

Certification:

-

CE ISO

-

Type:

-

Cold Tire Retreading Machine Autoclave

-

Control system:

-

PLC

-

COLOR:

-

Custom Made

-

Advantage 1:

-

High Efficient

-

Advantage 2:

-

Enviramental

Advantages of precure retread

The precure retreading process is kind to the carcass, since vulcanisation temperatures are lower and put less strain on the rubber-metal bonds in the carcass. Heat build-up in the tyre, rolling resistance and other tyre properties are often easier to assess than with hot retreading.

With comparable tread geometries, the running performance of a precured retread is often better than a hot retread and the same

as an equivalent new tyre.

Less investment is required on the part of the retreading plant (no expensive moulds) and lower follow-up costs, since it is the material supplier who updates the range of moulds.

A wide range of tread types are available, allowing the optimum tread to be selected for the tyre application.

The comparatively low investment costs involved mean that decentralised, smaller production units can be operated.

This means lower logistics costs and makes the operator more flexible and closer to his customers.

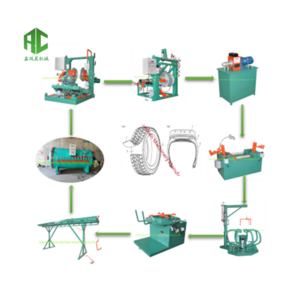

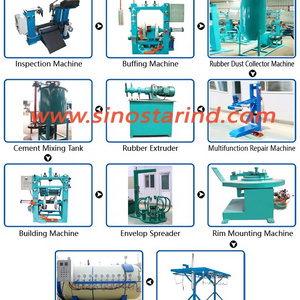

1 complete tyre retreading machine production line including:

Multifunctional vulcanizing tank, tyre polishing machine, vacuum cleaner, tire repair machine, tread pressing machine, Envelope Mounting & Dismounting Machine , Steel Rim Mounting & Dismounting Machine , Envelope Mounting & Dismounting Machine, Extruding Gun and so on.

Tyre retreading use all kinds of accessories. Including vulcanizing tank with 4, 6, 8, 10, 12, 16, 18, 24 tyre and so on.

2 tyre retread process:

3 machine introduction

4 f actory workshop

5 tyre before retread

6 tyre after retread

Exibition & Customers

All the product are CE,ISO,SGS Approved.

Packaging Details: Wood Pallet & Film Wrap

Delivery Detail: 60 Working Days Since Down Payment

1.

pre-sale services

Act as a good adviser and assistant of client enable them to get rich and generous returns on their investments.

1)select equipment model

2)design and manufacture products according to clients' special request

3)train technical personnel for clents.

2.services during the sale

1)Recheck and accept products ahead of delivery

2)Help clients to draft solving plans

3.after-sale services

1)provide considerate services to minimize client's worries.

2)Help client to solve the assembly question

3)take responsibility if any technical problem

Q:Are you factory or trading company?

A: We are a manufacturer with over than 15years of experience in Rubber Machine.

which include: plate vulcanizing press, open rubber mixing mill, banbury intensive kneader, extruder, rubber machinery, textile machinery,shot blast cleaning machine, foundry machinery, woodworking machinery, wheel barrow and tire etc

Factory Add: Huang Shan Economic Zone, Jiaonan, Qingdao, Shandong, China (Mainland)

Welcome your visiting and we can arrange our driver to pick up you.

Q:What advantages do you have?

We have15 years trust of our customers. Guarantee Quality and timely Delivery !

Skilled QC staff and do the best quality control,Fast shipment as per customers requirement.

Q: What are your delivery times?

The delivery time is 20-45 days after order be confirmed. For the exact date,please check with our sales team.

Q:What kind of surface treatment do you provide for your goods?

Galvanized ,chrome coating or powder coating are available. We can also make it according to our customer’s requirement.