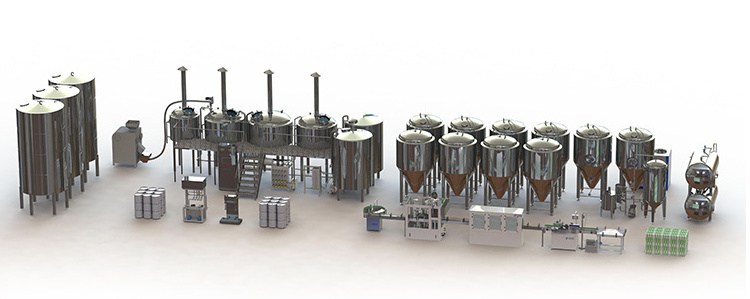

The whole system can be designed to different types, the most types are as following combinations, you can choose the type of brewhouse based on your brewing request.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

adjustable according to volume

-

Dimension(L*W*H):

-

customized

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product 2021

-

Product Name:

-

Tonsen Micro Brewery 500l Craft Beer Brewery Equipment For Sale

-

Application:

-

Brewing Plant

-

Function:

-

Brewing Wine Brewing Equipment

-

Heating method:

-

Electric Heating Steam Heating

-

Cooling way:

-

Dimple Plate Cooling Jacket

-

Control system:

-

Pressure Auto Control

-

Cleaning way:

-

Rotary Spray Cleaning Ball

-

Surface:

-

Brushed Stainless Steel

-

Keywords:

-

Microbrewery System

-

Plants Type:

-

Turkey Brewery

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

110v,220v, 380v, adjustable

-

Power:

-

adjustable according to volume

-

Dimension(L*W*H):

-

customized

-

Weight:

-

500 KG

-

Marketing Type:

-

New Product 2021

-

Product Name:

-

Tonsen Micro Brewery 500l Craft Beer Brewery Equipment For Sale

-

Application:

-

Brewing Plant

-

Function:

-

Brewing Wine Brewing Equipment

-

Heating method:

-

Electric Heating Steam Heating

-

Cooling way:

-

Dimple Plate Cooling Jacket

-

Control system:

-

Pressure Auto Control

-

Cleaning way:

-

Rotary Spray Cleaning Ball

-

Surface:

-

Brushed Stainless Steel

-

Keywords:

-

Microbrewery System

-

Plants Type:

-

Turkey Brewery

BREWING PRODUCT LIST

SHANDONG TONSEN EQUIPMENT CO., LTD.

|

CRAFT BEER BREWING EQUIPMENT / MICRO BREWERY EQUIPMENT STAND SETUP LIST:

|

|

|

|

|||

|

|

Components

|

Specification

|

|

|||

|

Milling system

|

Flex Auger

|

Stainless steel

|

|

|||

|

|

Grist case

|

SUS304

|

|

|||

|

|

Miller

|

Double Roller,Noise<60db

|

|

|||

|

Heating System

|

Boiler (steam heating)

|

Electric or steam or direct fire

|

|

|||

|

Brewhouse System |

Mash / Lauter tun

|

Heating jacket

Material: SUS 304/316 or Red copper 1 Thermometer / tank |

|

|||

|

|

Boiling / Whirlpool Tank

|

|

|

|||

|

|

Heat-exchanger

|

Plate type

|

|

|||

|

Fermentation System |

Fermentation Tank

|

Top manway/Side manway , Glycol cooling jacket

|

|

|||

|

|

Yeast Adding Tank

|

SUS304 Stainless Steel

|

|

|||

|

Refrigerator System |

Refrigerator machine

|

With control system

|

|

|||

|

|

Pump / valve

|

|

|

|||

|

|

Ice water tank

|

Fluorine filling

|

|

|||

|

CIP Cleaning System |

Acid Tank

|

SUS304 full welded |

|

|||

|

|

Alkali Tank

|

|

|

|||

|

|

Pump

|

|

|

|||

|

Control System

|

Control Cabinet

|

Semi-automatic

|

|

|||

|

Filtering System

|

Candle type diatomite filter/Membrane filter/Bag filter

|

|

|

|||

|

|

Bright beer tank

|

Double-layer with insulation;

|

|

|||

|

Filling System

|

Glass bottle line

|

Manual/semi-auto/full auto type

|

|

|||

|

|

Canning line

|

Manual/semi-auto/full auto type

|

|

|||

|

|

Keg system

|

Manual/semi-auto/full auto type

|

|

|||

BREWING PRODUCT DETAILS

SHANDONG TONSEN EQUIPMENT CO., LTD.

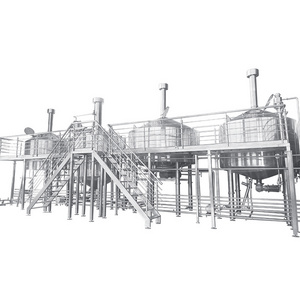

Mash system

We can provide 2 vessel, 3 vessel or combination system brewhouse according to your requirement and brewing process.

Good abrasion resistance material

Inner-Jacket(SUS304)thickness: 3.0mm

External-Jacket thickness: 2.0mm

High quality insulation effect

Beautiful weld and polish technology

All argon gas protection welding. Polishing precision up to Ra<0.6µm.

Powerful technology supporting

Providing drawing of every tank and drawing the layout of the whole project according with customer's workshop

High quality insulation effect

Beautiful weld and polish technology

All argon gas protection welding. Polishing precision up to Ra<0.6µm.

Powerful technology supporting

Providing drawing of every tank and drawing the layout of the whole project according with customer's workshop

Fermenting system

All AISI-304 Stainless Steel Construction

Jacketed & Insulated

Dual Zone Dimple Cooling Jacket

Dish Top & 60° Conical Bottom

4 Stainless Steel Legs with Leveling Ports

Jacketed & Insulated

Dual Zone Dimple Cooling Jacket

Dish Top & 60° Conical Bottom

4 Stainless Steel Legs with Leveling Ports

Fermenter Includes:

Top Manway or Side Shadow less Manway

Racking Port with Tri-Clover Butterfly Valve

Discharge Port with Tri-Clover Butterfly Valve

2 Tri-Clover Outlets with Butterfly Valves

CIP Arm and Spray Ball

Sample Valve

Racking Port with Tri-Clover Butterfly Valve

Discharge Port with Tri-Clover Butterfly Valve

2 Tri-Clover Outlets with Butterfly Valves

CIP Arm and Spray Ball

Sample Valve

Spunding valve

Pressure Gauge

Safety Valve

Thermowell

Pressure Gauge

Safety Valve

Thermowell

Hops adding port

Glycol inlet/outlet

Adjustable bolts

CO2 port with carbonation stone (option)

Ladder

hangers

Working pressure:2-3bars

Vertical Bright Beer Tank

BBT, Bright Beer Tanks, cylindrical pressure tanks, serving tanks, beer final conditioning tanks, beer storage tanks – these are

the most common terms, including the same class of special pressure vessels designed to preparation of carbonated beer before its

bottling, filling into kegs or other containers. Purified carbonated beer is pushed from lager beer tanks or cylindrically-conical tanks into pressure storage beer tank under pressure up to 3.0 bar.

This tank type also serves as a target tank when beer filtering or beer pasteurisation.

the most common terms, including the same class of special pressure vessels designed to preparation of carbonated beer before its

bottling, filling into kegs or other containers. Purified carbonated beer is pushed from lager beer tanks or cylindrically-conical tanks into pressure storage beer tank under pressure up to 3.0 bar.

This tank type also serves as a target tank when beer filtering or beer pasteurisation.

Malt Milling Unit

Particle adjustable rolling crusher

Flexible or steel auger to directly lift the milled grain to mash tun

Flexible or steel auger to directly lift the milled grain to mash tun

Cooling Unit

-Insulated glycol water tank with or without copper coil for glycol liquid holding and mixing

-Efficiency chillers or refrigerators with fryon to supply cooling energy

-Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

-All pipes, fitting, insulation materials are included

-Efficiency chillers or refrigerators with fryon to supply cooling energy

-Sanitary centrifugal pump for glycol water recycle among tanks and heat exchanger

-All pipes, fitting, insulation materials are included

CIP system

-Material SS304, Thickness for tank: 2mm

-Heating power for Alkali Tank 2-10KW

-Tank amount 2 or 3pcs: Sterilization tank, Alkali liquor tank and cleaning water tank.

-Separate control for CIP unit.

-Heating power for Alkali Tank 2-10KW

-Tank amount 2 or 3pcs: Sterilization tank, Alkali liquor tank and cleaning water tank.

-Separate control for CIP unit.

Control system

-Electrical controlling cabinet with temperature, on-off controlling for brewhouse

-Electrical controlling cabinet with temperature, on-off controlling for fermenter automatic.

-Temperature controller, thermocouple, solenoid valves etc are included

-PLC with touch screen panel for special request

-Electrical controlling cabinet with temperature, on-off controlling for fermenter automatic.

-Temperature controller, thermocouple, solenoid valves etc are included

-PLC with touch screen panel for special request

Hop gun system

“Dry hopping”, also referred to as “cold-hopping” in the business, is a procedure with which precious essential oils are released from the lupulin contained in the hops in beer. Dry hopping is performed after the brewing process in the cold area. At this point in time, the beer is finished but has yet to fully mature.

Our dry hopping system is flexible to use, with the hop quantity, the hop dosing time and duration being freely selectable. Cleaning can be performed manually or with an external CIP system.

Our dry hopping system is flexible to use, with the hop quantity, the hop dosing time and duration being freely selectable. Cleaning can be performed manually or with an external CIP system.

DISTILLATION EQUIPMENT

Equipment is multifunction style, you can change the direction of tee joint to decide the spirit you want. This style can make

Vodka, Whisky, Brandy, Rum,GIN

and so on.

Glass bottle filling and capping machine 200-500BPH

We can provide you beer filling machine from 100-500bottles per hour, also you can choose manual and semi-automatic system.

The Filling Systems provide a wide range of automatic & manual isobaric (counter-pressure) beer bottling and canning machines including efficient semi-automatic rinser, filler & capper/ seamer monoblocks.

These beer filling lines can also be used for bottling a wide range of sparkling and still drinks such as water, wine, cider, kombucha, soft drinks and carbonated drinks.

The filling line we can provide 1000BPH Line, 2000BPH Line, 3000BPH Line, 5000BPH Line, 6000BPH Line, 8000BPH Line according toyour brewery capacity.

The Filling Systems provide a wide range of automatic & manual isobaric (counter-pressure) beer bottling and canning machines including efficient semi-automatic rinser, filler & capper/ seamer monoblocks.

These beer filling lines can also be used for bottling a wide range of sparkling and still drinks such as water, wine, cider, kombucha, soft drinks and carbonated drinks.

The filling line we can provide 1000BPH Line, 2000BPH Line, 3000BPH Line, 5000BPH Line, 6000BPH Line, 8000BPH Line according toyour brewery capacity.

Keg washer

Main function and feature

1.Automatic control by PLC, all parameters can be adjusted through touch screen.

2.Cleaning and filling process can be finished in this machine at one time.

3.All use pneumatic double acting Angle seat valve which could ensure the action sensitivity and reliability

4.With unique pressure maintaining system,performance stable and reliable, beer loss minimum.

5.With CIP automatic cleaning system

We can also provide you keg filler, All in one keg filler and washer machine, let us your request, and we will give you a solution.

BEER KEGS

A beer tap is a valve, specifically a tap, for controlling the release of beer. While other kinds of tap may be called faucet,valve or spigot, the use of tap for beer is almost universal.

FOR OTHER BREWERY RELATED PRODUCTS,CONTACT US DIRECTLY!

ABOUT TONSEN

SHANDONG TONSEN EQUIPMENT CO., LTD.

Shandong Tonsen Equipment Co., Ltd.

, located in Jinan, China, covers an area of about

20,000 square meters

, More than 100 employees , the project managers and technical engineers are all experienced with more than 20 years of work experience in the beer equipment industry. Keep learning and promoting advanced German and US beer technology. Nowadays we have many Exclusive advanced technology.

Tonsen obtained national high-tech enterprise. It has a number of invention patents and utility model patents. It has passed ISO9001 quality system certification, D-level pressure vessel production license (including design), EU CE certification, SGS certification, etc. A series of international and domestic system certifications.

SALES SERVICE

SHANDONG TONSEN EQUIPMENT CO., LTD.

The most honest partner of global breweries, We provide you with guaranteed quality service!

WHY CHOOSE TONSEN

SHANDONG TONSEN EQUIPMENT CO., LTD.

***The material is

Food-grade SUS304 stainless steel

, all of which are from

ZHANGJIAGANG POSCO

or

SHANXI TISCO.

***The chief designer has more than 20years of experience in beer equipment design , with advance technology design concept.

***Plasma cutting, professional polishing equipment, 100% argon arc welding,and argon gas protection.

***Short delviery cycle, round the clock after-sales service.

*** Use ABB motor for all brewing pumps, with small noise, high efficiency; The small vart of home brew equipment uses wheel, move

freely.

****Provice on-site fuidance and installation services, and provide free beer trainning and formulation.

Three years warranty on main equipment, One year warranty on spare partsand auxilloary equipment.

Where to buy beer brewing equipment with high quality and good price ?

Please leave messsage in below to get our latest quote and equipment list for beer filter or turnkey brewery.

***The chief designer has more than 20years of experience in beer equipment design , with advance technology design concept.

***Plasma cutting, professional polishing equipment, 100% argon arc welding,and argon gas protection.

***Short delviery cycle, round the clock after-sales service.

*** Use ABB motor for all brewing pumps, with small noise, high efficiency; The small vart of home brew equipment uses wheel, move

freely.

****Provice on-site fuidance and installation services, and provide free beer trainning and formulation.

Three years warranty on main equipment, One year warranty on spare partsand auxilloary equipment.

Where to buy beer brewing equipment with high quality and good price ?

Please leave messsage in below to get our latest quote and equipment list for beer filter or turnkey brewery.

Hot Searches