- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Power:

-

34.7Kw/h

-

Weight (KG):

-

35000

-

Product name:

-

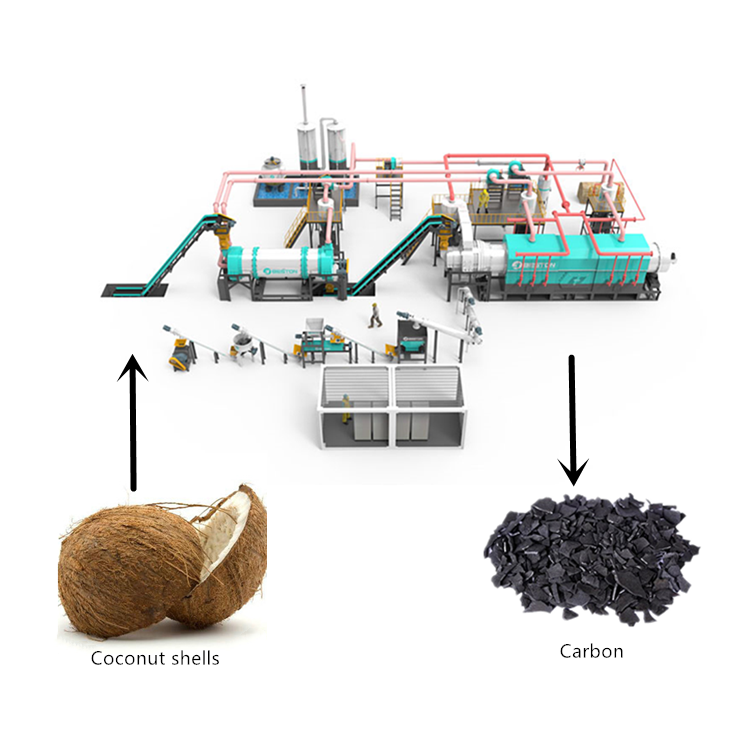

Coconut Shell Charcoal Making Machine

-

Keywords:

-

Charcoal Making Machine

-

Application:

-

Making Charocal

-

Raw material:

-

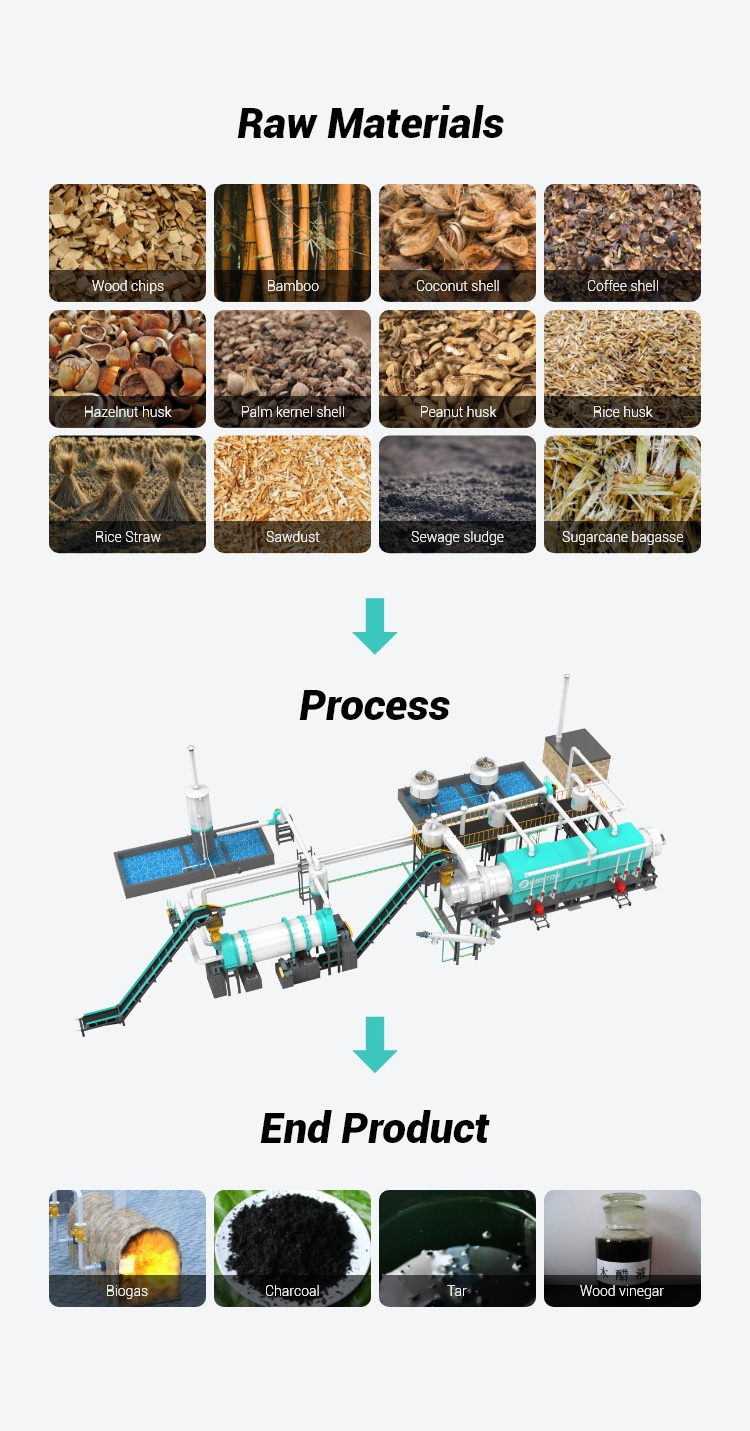

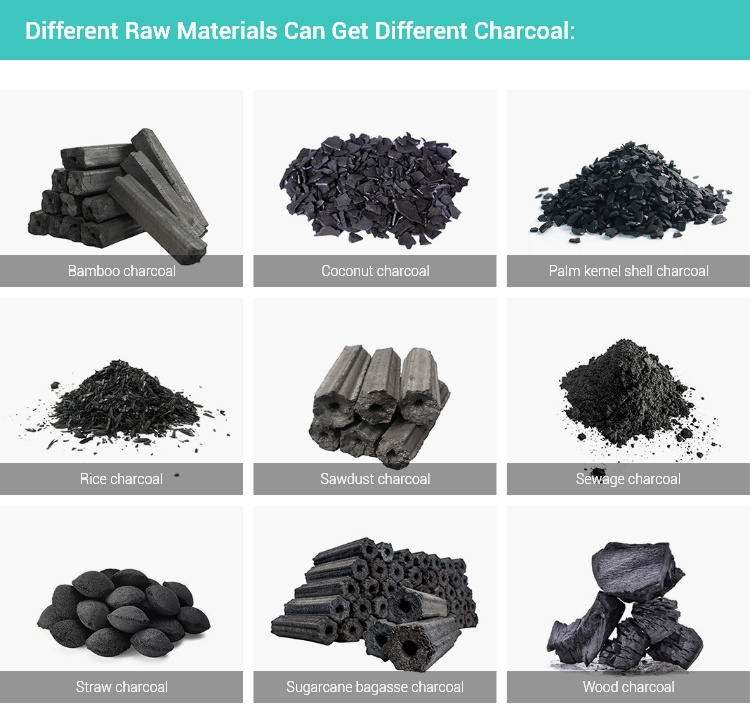

Coconut shell, Rice husk, straw, bits of wood, Palm Shell

-

Color:

-

Customer's Request

-

Final product:

-

Charcoal

-

Installation:

-

Engineer Guide

-

Advantage:

-

Continuous Working Environment Friendly

-

Service:

-

24hrs

-

Function:

-

Carbonization

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Beston Group

-

Dimension(L*W*H):

-

29m*15m*5m

-

Voltage:

-

380V

-

Power:

-

34.7Kw/h

-

Weight (KG):

-

35000

-

Product name:

-

Coconut Shell Charcoal Making Machine

-

Keywords:

-

Charcoal Making Machine

-

Application:

-

Making Charocal

-

Raw material:

-

Coconut shell, Rice husk, straw, bits of wood, Palm Shell

-

Color:

-

Customer's Request

-

Final product:

-

Charcoal

-

Installation:

-

Engineer Guide

-

Advantage:

-

Continuous Working Environment Friendly

-

Service:

-

24hrs

-

Function:

-

Carbonization

Product Description

What is continuous charcoal making machine?

Beston Group continuous charcoal machine

can continuously produce coconut shells, peanut shells, rice husks, wood, wood chips, sewage sludge, etc. into various charcoal through the carbonization process, which can realize automatic feeding and automatic unloading, and environmental protection and energy saving.

Successful Cases

BST-50 Charcoal Making Machine in Turkey

BST-10 Sawdust Charcoal Making Machine in Finland

BST-05 Palm Kernel Shell Charcoal Machine in UAE

BST-05 Sawdust Charcoal Making Machine in Ghana

BST-10 Sludge Carbonization Machine to Serbia

BST-10 Sawdust Charcoal Making Machine to Nigeria

Product Models

|

Model

|

BST-J12

|

BST-J18

|

BST-J40

|

BST-05 Pro (skid-mounted)

|

BST-10

|

BST-30

|

BST-50

|

|||||

|

Input Capacity

|

12m³/h/batch

|

18m³/h/batch

|

40m³/h/batch

|

0.3-0.5m³/h (300kg/h)

|

2-4m³/h (1000kg/h)

|

7-9m³/h (3000kg/h)

|

10-15m³/h (5000kg/h)

|

|||||

|

Reactor Size

|

φ1900mm*L4500mm

|

φ1900mm*L6600mm

|

φ2800mm*L7100mm

|

φ830mm*L5500mm

|

φ1300mm*L14051mm

|

φ1700mm*L14180mm

|

φ2000mm*L14260mm

|

|||||

|

Land for Equipment (L*W*H)

|

9m*6m*6m

|

12m*6m*7m

|

15m*18m*7m

|

10m*8m*3.9m

|

29m*15m*5m

|

30m*15m*8m

|

35m*18m*9m

|

|||||

|

Weight

|

18T

|

22T

|

34T

|

15T

|

35T

|

35T

|

49T

|

|||||

|

Energy Consumption

|

11kw/h

|

13.5kw/h

|

25kw/h

|

31kw/h

|

34.7kw/h

|

61.5kw/h

|

116kw/h

|

|||||

|

Working Method

|

Batch

|

|

|

Fully continuous

|

|

|

|

|||||

Main Parts

Product Advantages

Packing & Delivery

Hot Searches