- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DESG

-

Voltage:

-

380v OR custom madeC

-

Dimension(L*W*H):

-

1925*1560*1490mm

-

Weight (KG):

-

1950

-

Name:

-

Cnc Busbar Cutting Punching Bending Machine

-

Certification:

-

CE ISO

-

Machine Type:

-

CNC Control

-

Color:

-

Photos

-

Power:

-

3*5.5KW

-

Punching Force:

-

500KN

-

MOQ:

-

1set

-

Bending Force:

-

800KN

-

Cutting Force:

-

500KN

-

Funtion:

-

CNC Control

Quick Details

-

Max. Thickness (mm):

-

16 mm

-

Max. Width (mm):

-

260 mm

-

Warranty of core components:

-

3 Year

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DESG

-

Voltage:

-

380v OR custom madeC

-

Dimension(L*W*H):

-

1925*1560*1490mm

-

Weight (KG):

-

1950

-

Name:

-

Cnc Busbar Cutting Punching Bending Machine

-

Certification:

-

CE ISO

-

Machine Type:

-

CNC Control

-

Color:

-

Photos

-

Power:

-

3*5.5KW

-

Punching Force:

-

500KN

-

MOQ:

-

1set

-

Bending Force:

-

800KN

-

Cutting Force:

-

500KN

-

Funtion:

-

CNC Control

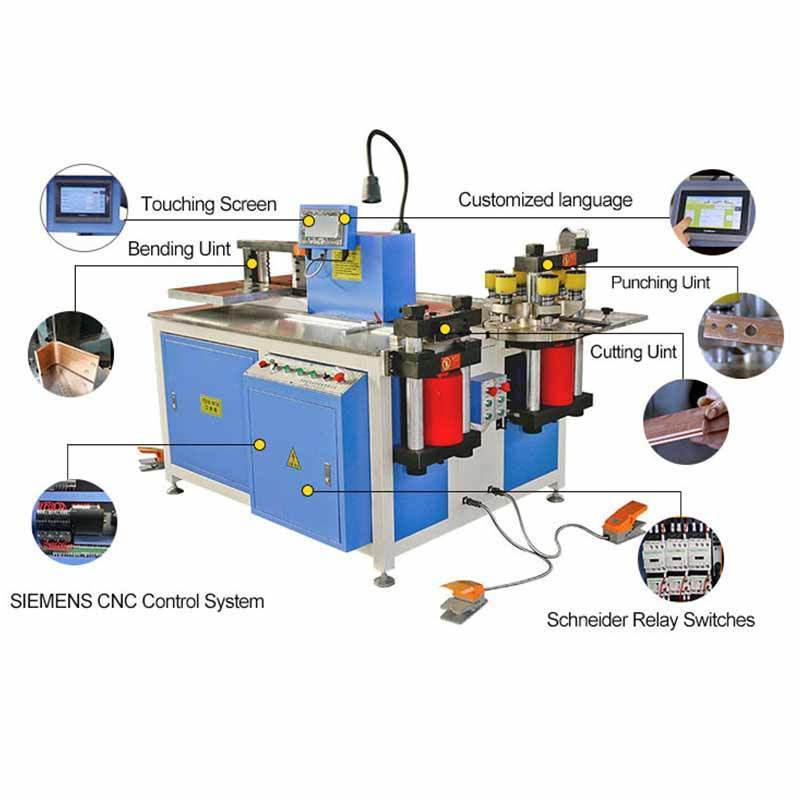

Product Description

The advantage of the DSMX-503esk-b CNC busbar machining machine is that the three machining positions work simultaneously without

affecting each other. The unit adopts Siemens PLC from Germany

affecting each other. The unit adopts Siemens PLC from Germany

The main Function

Punching、Cutting、Flat Bend、Bending、Embossing、U-Bend、Back FlatChamfer、Twist Bend、Compression Cable End

Technical parameters

|

Busbar Machine Model

|

|

DSMX-503ESK-B

|

|

|

Punching

|

Max.Puncing Force (KN)

|

500

|

|

|

|

Punching Diameter Range (MM)

|

Ø4.3-Ø36

|

|

|

|

Max. Thickness (MM)

|

16

|

|

|

|

Max. Width (MM)

|

260

|

|

|

Shearing/

Cutting |

Max.Shearing Thickness(KN)

|

16

|

|

|

|

Max. Shearing Width (MM)

|

260

|

|

|

|

Max. Bending Force (KN)

|

800

|

|

|

Vertical Bending

|

Max. Thickness (MM)

|

10

|

|

|

|

Max. Width (MM)

|

100

|

|

|

Horizontal Bending

|

Max. Width (MM)

|

16

|

|

|

|

Max. Width (MM)

|

260

|

|

|

Twisting Bending

|

Max. Thickness (MM)

|

16

|

|

|

|

Max. Width (MM)

|

260

|

|

|

Out Dimension

|

Out Dimension

|

1925*1560*1490

|

|

|

Power

|

Power

|

3 x 5.5kw

|

|

|

CNC Precision

|

Bending Precision

|

±1°

|

|

|

|

Repeat Bending Precision

|

±0.3°

|

|

Product Details

Cutting Uint:Double-column cut structure

The cutting station adopts a double-column structure , the cutting mouthis flat no waste , no buns , no collapseangles.

Bending Unit:Convenient and easy to operate

The bending unit adopts anindependentworkbench , and thethree processing unitswork at thesame time without affectingeachother The processing of flat bendingand verticalbending can be completedby changing the die.

Punching Unit:Nodular cast iron material

The punching unit adopts atoothedsix-position integral turntablewhichhas a good line of sight, highstrengthaccurate positioning, andprecise punchingwithout offsetthere is no need to change themoldfrequently, improve work efficiencyanduse more convenient and faster.

Product Samples

Multifunctional Combined Busbar Machine Complete : punching cutting bending functions Small size/convenient and fast/punchingwithout burrs/cutting without waste

Product Hot Sales

|

Model

|

DSMX-70

|

|

Functions

|

Cut/ Punch /Bend

|

|

voltage

|

220V/380V

|

|

oil pressure

|

700kgf/cm²

|

|

Output of cutting machine

|

35T

|

|

Bus bar cuttting capability

|

200mm×12mm

|

|

Output of bus bar cutter

|

35T

|

|

Depth of throat

|

110mm

|

|

Standard setting

|

Ø 7, Ø 9, Ø 10.5, Ø 13.8, Ø 17.5, Ø 20.5mm

|

|

Punching capacity

|

Ø 6 - Ø 20.5mm

|

|

Output of bending machine

|

15T

|

|

Bending capacity

|

200mm x12mm

|

|

Weight

|

230kg

|

|

Size

|

840 x900 x1200mm

|

|

Model

|

CH-60

|

CH-70

|

|

|

Output

|

31T

|

35T

|

|

|

Depth of throat

|

95mm

|

110mm

|

|

|

Angle steel

|

4-8#

|

5-10#

|

|

|

Channel steel

|

6-10#

|

6-12#

|

|

|

Copper and aluminum row

|

3-10mm

|

3-12mm

|

|

|

iron plate

|

3-8mm

|

3-10mm

|

|

|

Standard setting

|

Ø10.5,Ø 13.8,Ø 17.5,Ø 20.5

|

Ø10.5,Ø 13.8,Ø 17.5,Ø 20.5

|

|

|

Weight

|

20kg

|

35kg

|

|

|

Volume

|

350x220x75mm

|

350x265x115mm

|

|

|

Product features

|

Portable hydraulic punching machines are suitable for L, H flat steel, copper and aluminum punching machines. The bottom is

designed with a flat seat, which is stable and not easy to sway. Single hole oil return, the mold is made of high carbon tungsten alloy steel, which is not easily damaged. |

|

|

|

Model

|

Output

|

Thickness of sheet

|

Width of sheet

|

Size

|

Weight

|

||||

|

CWC-150

|

25T

|

2-10mm

|

≤150mm

|

270x150x410mm

|

30kg

|

||||

|

CWC-200

|

35T

|

2-12mm

|

≤200mm

|

325x150x435mm

|

38kg

|

||||

|

Product features

|

Suitable for wiring engineering of switch boxes and automatic control panels of distribution boards, adopting a separate type for easy portability. Single hole oil return, especially suitable for outdoor construction operations in industries such as power and construction.

|

|

|

|

|

||||

|

Model

|

Output

|

Thickness of sheet

|

Width of sheet

|

Size

|

Weight

|

||||

|

CB-150D

|

20T

|

≤10mm

|

≤150mm

|

360x130x260mm

|

21kg

|

||||

|

CB-200A

|

25T

|

≤12mm

|

≤200mm

|

215x180x350mm

|

29kg

|

||||

|

Product features

|

Suitable for wiring engineering of switch boxes and automatic control panels of distribution boards, adopting a separate type for easy portability. The minimum bending angle of copper or aluminum bars can reach 90 degrees. Single hole oil return, especially for outdoor construction operations in industries such as powerand construction

|

|

|

|

|

||||

|

Model

|

Electric pump

|

|

|

|

Extra work pressure

|

63MPA

|

70MPA

|

|

|

Flow

|

1L/min

|

1L/min

|

|

|

Power of motor

|

750W

|

750W

|

|

|

Voltage

|

220V

|

220V

|

|

|

Oil storage capacity

|

5L

|

5L

|

|

|

Overall dimensions

|

350x270x490

|

350x270x490

|

|

|

Control mode

|

Electromagnetic valve foot switch

|

Electromagnetic valve foot switch

|

|

Product Application

Mainly used for processing various types of copper and aluminum bars such as high and low voltage switchgear, substations, transformers, electrical switches, chassis cabinets, large bus ducts, etc.

Mainly used for processing various types of copper and aluminum bars such as high and low voltage switchgear, substations, transformers, electrical switches, chassis cabinets, large bus ducts, etc.

Product packaging

Packed in standard import and export wooden boxes, free from fumigation and treated with rust prevention.

FAQ

1.What is your payment terms?

40% T/T deposit, 60% balance be paid before loading after good ready.

2. What is your delivery time?

Within 15 working days after your deposit.

3. What is your power supply?

We could customized it according to your countries power supply.

4. What is your Min order quantity?

One set.

5. Are all the labels and instuctions of the machine in English?

Yes. The labels on the machine and the manual books are Write in English .

6. What other busbar processing related machines do we provide?

We provide you with multiple options:

Busbar winding machine, busbar chamfering machine, copper plate leveling machine, portable busbar processing machine,busbar cutting tools, busbar bending tools, busbar punching tools,hydraulic pump, hand pump, etc.

Hot Searches