Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

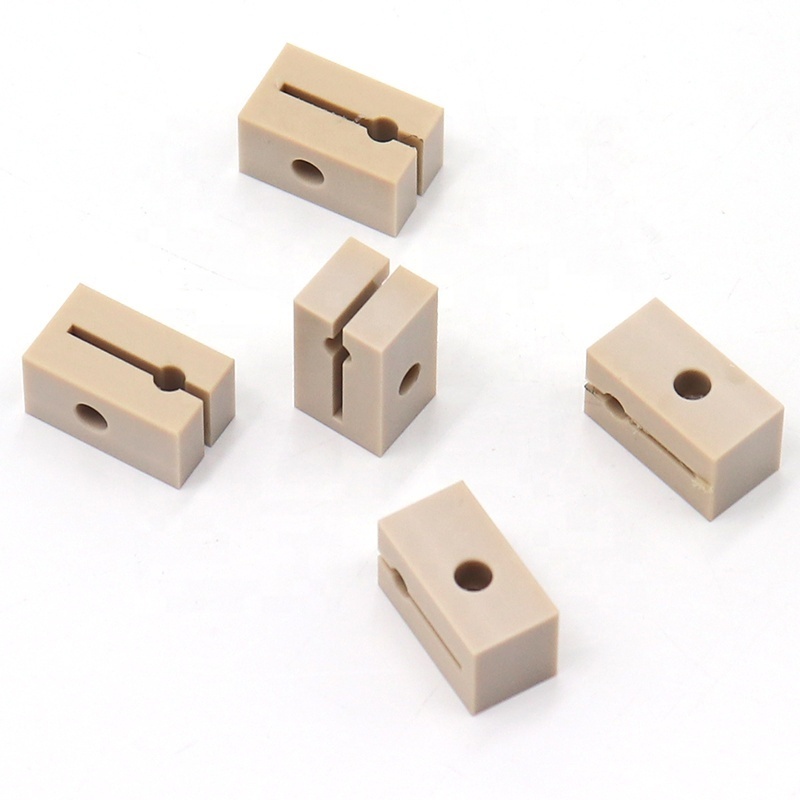

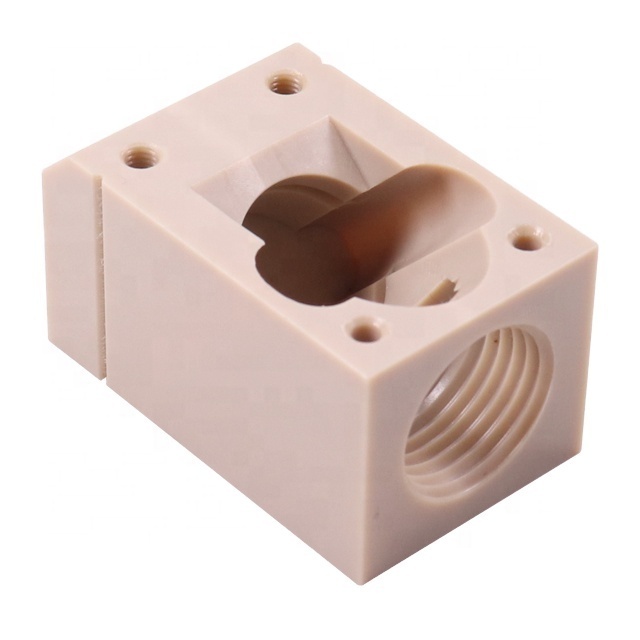

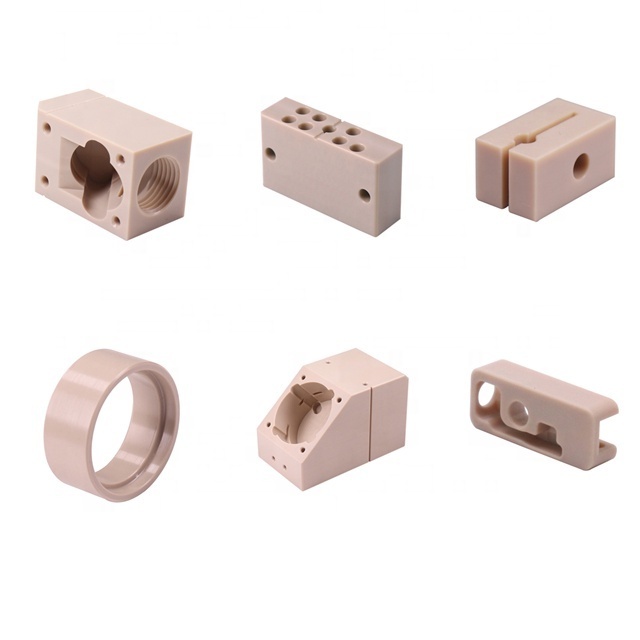

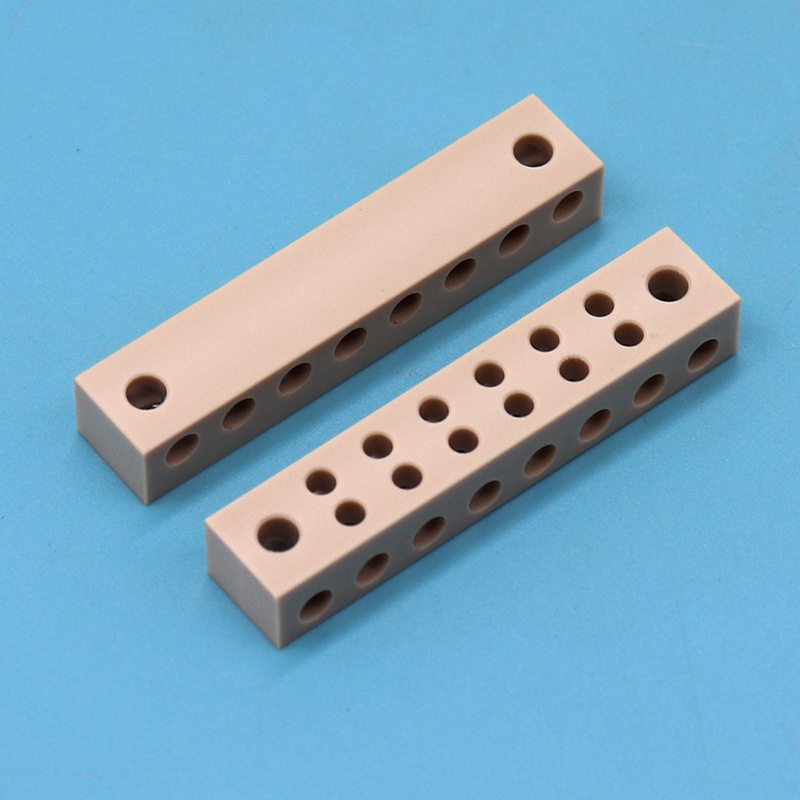

Cnc Machining Peek Plastic Part

-

Brand Name:

-

RuiXing

-

Product name:

-

Machined Peek Plastic Medical Precision OEM CNC Machined Peek Part

-

Size:

-

As per requirement

-

Product Material:

-

Natural PEEK

-

Surface treatment:

-

None

-

Processing Type:

-

CNC Turning Milling Machining

-

Roughness:

-

Ra3.2

-

Service:

-

Customized OEM

-

MOQ:

-

5pcs

-

Sample delivery:

-

Air express

Quick Details

-

CNC Machining or Not:

-

Cnc Machining

-

Material Capabilities:

-

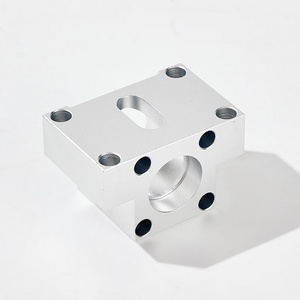

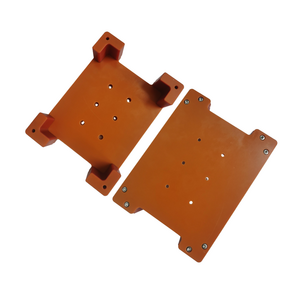

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, Plastic

-

Place of Origin:

-

Shenzhen, China

-

Model Number:

-

Cnc Machining Peek Plastic Part

-

Brand Name:

-

RuiXing

-

Product name:

-

Machined Peek Plastic Medical Precision OEM CNC Machined Peek Part

-

Size:

-

As per requirement

-

Product Material:

-

Natural PEEK

-

Surface treatment:

-

None

-

Processing Type:

-

CNC Turning Milling Machining

-

Roughness:

-

Ra3.2

-

Service:

-

Customized OEM

-

MOQ:

-

5pcs

-

Sample delivery:

-

Air express

Shenzhen Ruixing Precision MFG

Ruixing was founded in 2005 and passed ISO9001-2015. We are specialized in CNC machining parts for 18 years more. We are your

professional partner of machining parts manufacturing. We can provide you with professional services to ensure the smooth progress of your project.

Our service focus on supply the professional machining service for Industry Automation, Aerospace parts , Knitting Machine Parts, Instruments & Meters, Sensor, Medical Equipment, Beauty & Personal Care , Consumer electronics and hardware, etc.

We are well-experienced at all kinds of metal & plastic material. and provide surface treatment including anodizing, electroplating, PVD, powder coating, painting, polishing, heat treatment, laser engraving, laser welding, etc.

Our service focus on supply the professional machining service for Industry Automation, Aerospace parts , Knitting Machine Parts, Instruments & Meters, Sensor, Medical Equipment, Beauty & Personal Care , Consumer electronics and hardware, etc.

We are well-experienced at all kinds of metal & plastic material. and provide surface treatment including anodizing, electroplating, PVD, powder coating, painting, polishing, heat treatment, laser engraving, laser welding, etc.

One-stop service, saving you procurement time and costs, and achieving maximum

benefits.

benefits.

|

Materials

|

Natural PEEK

|

|

Surface Treatment

|

Natural

|

|

Tolerance

|

0.01-0.1mm

|

|

Testing equipment

|

CMM, Keyence Image measurer, Height gauge,Thread gauge, Pin gauge,etc

|

|

Application

|

Auto parts, Sensor , Instruments & Meters, Machinery parts, etc.

|

|

File Formats

|

PDF, Igs, Stp, Step, CAD, JPG, etc

|

|

Service Project

|

OEM ODM Customised

|

|

MOQ

|

5pcs

|

Q1: Are you direct manufacturer ?

A1: Yes, We are CNC parts manufacturer in ShenZhen, GuangDong

Q2: How to enjoy the OEM services?

A2: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q3: Will my drawings be divulged if you benefit?

A3: No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

A1: Yes, We are CNC parts manufacturer in ShenZhen, GuangDong

Q2: How to enjoy the OEM services?

A2: Usually, base on your design drawings or original samples, we give some technical proposals and a quotation to you, after your agreement, we produce for you.

Q3: Will my drawings be divulged if you benefit?

A3: No, we pay much attention to protect our customers’ privacy of drawings, signing NDA is also accepted if need.

Q4: How about the lead time?

Q5:Can we know the production process without visiting the factory?

A4: Generally, 1-2 weeks for samples, 3-4 weeks for mass production.

Q5:Can we know the production process without visiting the factory?

A5: We will offer detailed production schedule and send weekly reports

with digital pictures and videos which show the machining progress.

with digital pictures and videos which show the machining progress.

Hot Searches