- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ/3Phase

-

Power:

-

18KW

-

Dimension(L*W*H):

-

8000*1200*1100mm

-

Weight:

-

kg

-

Roller material:

-

SKD-11

-

Cutting blade material:

-

SKD-11

-

Shaft material:

-

40Cr

-

Design Software:

-

Vertex Software

-

Cutting type:

-

Hydraulic Cutting

-

Usage:

-

Building Projects

-

Decoiler:

-

Electric Decoiler

-

Forming Steps:

-

12 Steps

Quick Details

-

Production Capacity:

-

30m/min

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

XHH

-

Voltage:

-

380V/50HZ/3Phase

-

Power:

-

18KW

-

Dimension(L*W*H):

-

8000*1200*1100mm

-

Weight:

-

kg

-

Roller material:

-

SKD-11

-

Cutting blade material:

-

SKD-11

-

Shaft material:

-

40Cr

-

Design Software:

-

Vertex Software

-

Cutting type:

-

Hydraulic Cutting

-

Usage:

-

Building Projects

-

Decoiler:

-

Electric Decoiler

-

Forming Steps:

-

12 Steps

Focus on roll forming machine for more than

19

years

Factory

Lifetime Service

CE

Certificate

Best

Quality:

select all best material for roller,shaft,cutter,PLC and driving system

Customized

Profile:can design the profile according to customer request

Main Products

Products Description

The Technical Advantages of Using Light Steel Villa Machine:

1.Cost-effective

:

Light steel villa machines can greatly reduce labor costs and enhance production efficiency, making the construction process less time-consuming and more cost-effective.

2.High precision

:

Advanced light steel villa machines can achieve high precision and high-quality production, ensuring the accuracy and durability of the steel frames and components.

3.Sustainable and eco-friendly : Light steel villa machines are eco-friendly and sustainable, as they produce less waste and generate less pollution compared to traditional construction methods.

4.Easy to assemble : Light steel villa machines make the construction process simpler and faster, as the components are prefabricated off-site and then assembled on-site, reducing dependence on skilled labor and saving time.

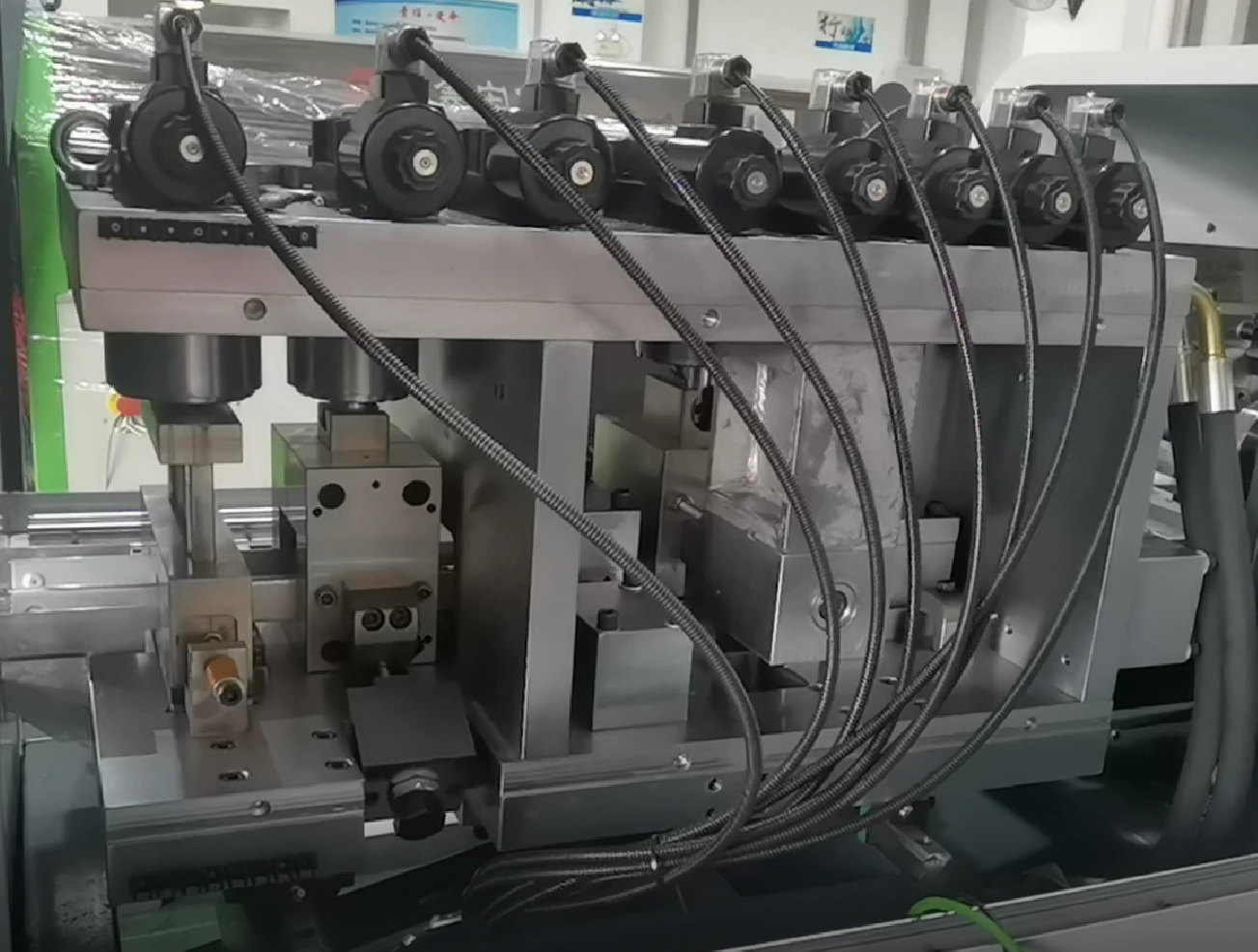

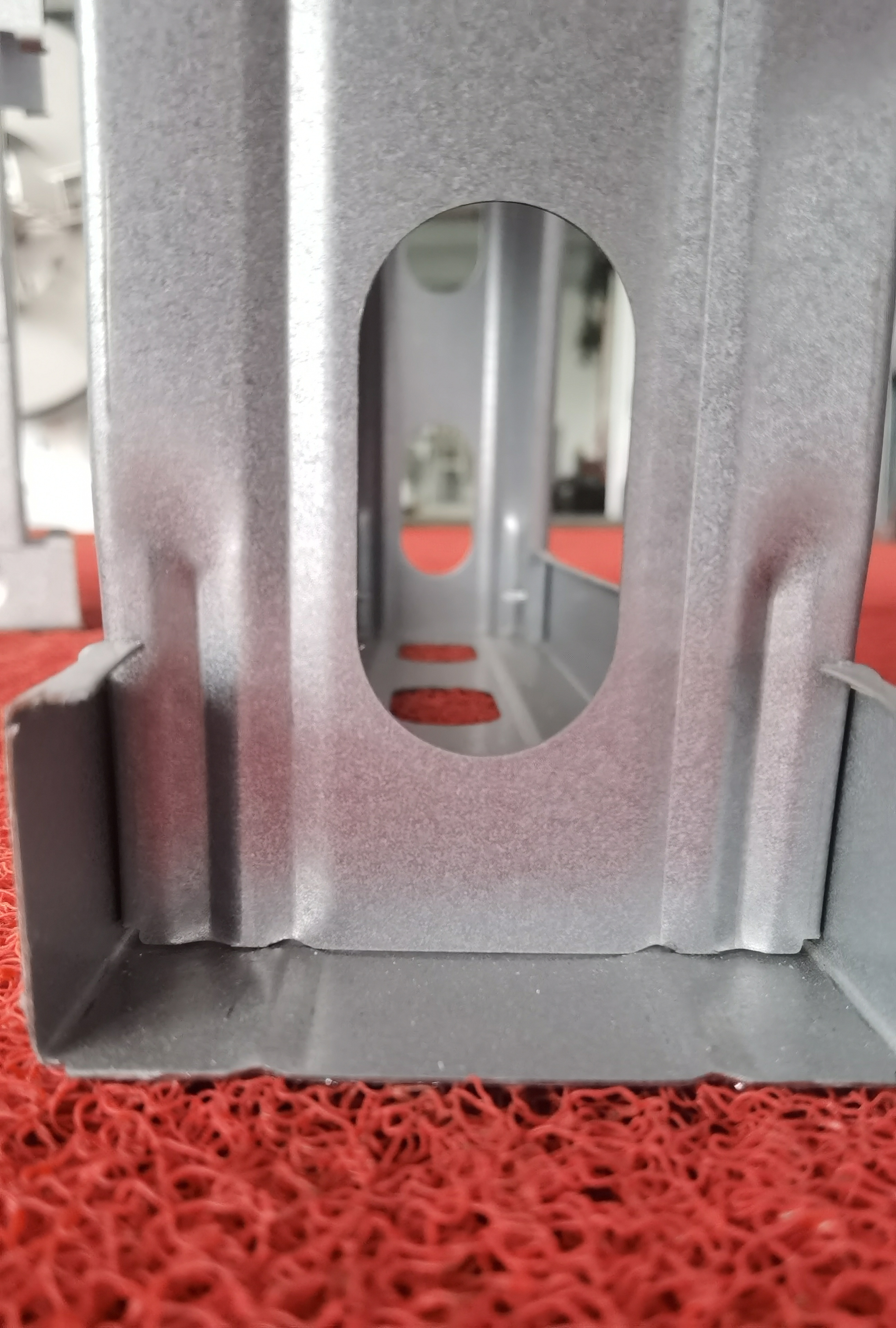

Post Punching Mould

XHH LGS Machine all with post punching and post cutting, which make more high precision performance on position & dimension

Seamless end cut connection

Seamless end-cut connection is a patent design of XHH LGS ROLL FORMER. The two ends of the vertical frame can seamlessly connect to the web of the bottom and top horizontal frames. So the weight of the house can be directly loaded and passed by the vertical

frame, which makes the house safer.

frame, which makes the house safer.

Lower material wasting

Short distance between punching & cutting die able to limit the start-up material waste length at 0.2m, and end material waste

length within 1 meter.

length within 1 meter.

Save cost:

1. The length of each start-up waste of the XHH post-punching & cutting machine is about

1M

; most machines on the market are pre-punching & post-cutting (other supplier), their waste material is about

8M

on each start-up;

|

Start-Up/Change Steel Coil

|

8.11-12.13 Kg

|

|

5 Steel Coils/Day

|

40.55-60.65 Kg

|

|

Material Saved/Year

|

12.17-18.2 T

|

2. XHH Machine steel strip width is: 170-174mm width, 10mm less than the most other machines in the market. For a 200sqm house, the total frame is around 7000m,can

save 439.6-659.4kg material

;

|

Material Thickness

|

0.8mm

|

1.0mm

|

1.2mm

|

|

Material Saved Per House

|

439.6kg

|

549.5kg

|

659.4kg

|

|

Main Accessories:

|

|

1) Main Forming Machine

|

|

2) 5 Tons Hydraulic Uncoiler

|

|

3) Servo Motor System

|

|

4) IPC Computer Controlling System (Lenovo Laptop)

|

|

5) Production Software (1set)

|

|

6) Design Software-Vertex,forever using license

|

|

7) Hydraulic Automatic Punching Device

(Web/Lip Notch,Swage,Service Hole,Chamfer,Dimple,Bolt Hole) |

|

8) Hydraulic Post-cutting Device (Material:SKD-11)

|

|

9) Automatic Printing Device

|

|

10) Run Out Table (4m)

|

|

11) Operation Manual

|

|

Main Technical Data:

|

|

|

Size

|

C63-89-140

|

|

Dimension

|

8000*1200*1100mm

|

|

Main Servo Motor Power

|

18KW

|

|

Hydraulic Motor

|

11kw

|

|

Forming Steps

|

12Steps

|

|

Forming Speed

|

30m/min(without punching and cutting)

|

|

Voltage

|

380V/50HZ/3PH

|

|

Effective Width for C

|

63mm,89mm,140mm

|

|

Flange Height

|

38mm,41mm

|

|

Lip

|

9-15mm

|

|

Material Thickness

|

0.6-1.2mm for 63/89 profile

0.8-1.5mm for 140 profile |

|

Tolerance for cutting and punching

|

±0.5mm

|

|

Tolerance for forming

|

±1mm

|

|

Control System

|

IPC Computer Controlling System

|

|

Design Software

|

Vertex Software

|

|

Material for All Roller

|

SKD-11 steel with heat treatment, plate hard chrome on the surface of rollers

|

|

Material for Shaft

|

SKD-11

|

|

Material for Puncher

|

SKD-11

|

|

Material for Cutter

|

SKD-11

|

Can not find the machine you need?

Why not customize it!

We have engineers with experience more than 17 years!

The configuration is not unique, we will provide you with customized services.

Product Application

Light Gauge Steel Framing Machine Overview

Fasting

Working Speed:4-5T/8Hours

Higher

Precision with 0.5mm

Post

-Punching System

Lower

Material Waste with 20cm

Hot Searches