Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

Packaging

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DMPACK

-

Model Number:

-

DMPACK-06

-

Product name:

-

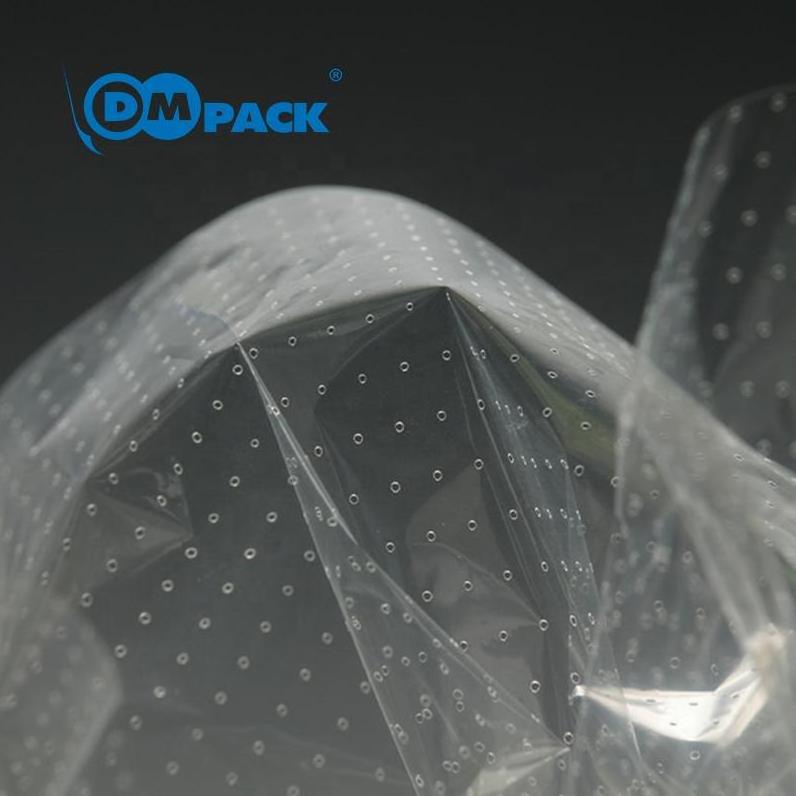

Common Standard Quality Polyolefin POF Shrink Film With Perforation

-

Application:

-

Package

-

Color:

-

Transparent, colored and opaquel

-

Thickness:

-

8.5micron to 50micron

-

Width:

-

100mm-2200mm

-

Certificate:

-

S G S, ISO9001, EU

-

Printing:

-

MAX 8 colors

-

Packing:

-

Wooden Pallet

-

MOQ:

-

1000kg

-

Delivery Time:

-

7-15 Days

Quick Details

-

Material:

-

Pof

-

Type:

-

Shrink Film

-

Use:

-

Packaging Film

-

Feature:

-

Moisture Proof

-

Industrial Use:

-

Packaging

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

DMPACK

-

Model Number:

-

DMPACK-06

-

Product name:

-

Common Standard Quality Polyolefin POF Shrink Film With Perforation

-

Application:

-

Package

-

Color:

-

Transparent, colored and opaquel

-

Thickness:

-

8.5micron to 50micron

-

Width:

-

100mm-2200mm

-

Certificate:

-

S G S, ISO9001, EU

-

Printing:

-

MAX 8 colors

-

Packing:

-

Wooden Pallet

-

MOQ:

-

1000kg

-

Delivery Time:

-

7-15 Days

Polyolefin (POF) shrink film is a biaxial oriented heat shrinkable wrapping film. It's used to bundle items or to protect your products from moisture, dust, theft, etc.

With our production of polyolefin POF shrink film sold and well tested on the largest producer of shrink packaging tunnel machines such as: “Hugo Beck, Smipack, Minipack Torre, Beck & Co., Kallfass, BVM, Ulma, Belca, Italdibipack…

We produce the film for big retailers in the world, in many cases they need a low quality to fight against their competitors with prices, reducing always the quality… THIS IS NOT OUR CASE !!!

We are able to offer high quality films, with the use of the most important raw material brand LLDPE (Dow Chemical) and PP (Basell), the highest quality!

There are many differences in quality, our film as better clarity, better shrink performance at lower temperatures, better welding (without wires or fumes), better machinability, and more softness, to avoid (big ears) on corners.

We have more than 20 years of experience in the production of this film, our machines are fully automatic with five extruders, (a new technology with seven layers), we provide the strongest high performance film at the thickness of 8.5 micron, designated for high speed machines.

Our prices are really competitive, and we can solve all your problems on your package, we can fulfill your requirement.

Our full range of shrink films are available in single wound, folded, cold-perforated, hot-perforated, and can be printed in up to eight colors.

We produce the film for big retailers in the world, in many cases they need a low quality to fight against their competitors with prices, reducing always the quality… THIS IS NOT OUR CASE !!!

We are able to offer high quality films, with the use of the most important raw material brand LLDPE (Dow Chemical) and PP (Basell), the highest quality!

There are many differences in quality, our film as better clarity, better shrink performance at lower temperatures, better welding (without wires or fumes), better machinability, and more softness, to avoid (big ears) on corners.

We have more than 20 years of experience in the production of this film, our machines are fully automatic with five extruders, (a new technology with seven layers), we provide the strongest high performance film at the thickness of 8.5 micron, designated for high speed machines.

Our prices are really competitive, and we can solve all your problems on your package, we can fulfill your requirement.

Our full range of shrink films are available in single wound, folded, cold-perforated, hot-perforated, and can be printed in up to eight colors.

Parameter Data

| Main Parameter Data | |||||||

| Property | Unit | Test Method | Representative Value | ||||

| PHYSICAL PROPERTY | |||||||

| Thickness | Micron | 12.5 | 15 | 19 | 25 | 30 | |

| TENSILE PROPERTY (MD/TD) | |||||||

| Tensile Strength | N/mm2 | ASTM/882 | 110/110 | 110/110 | 110/110 | 100/100 | 100/100 |

| Elongation at Break | % | ASTM/882 | 90/90 | 90/90 | 95/95 | 100/100 | 110/110 |

| Seal Strength | 180°C N/15mm | ASTM F88 | 12.6 | 13.8 | 19.1 | 24.2 | 27.6 |

| Tear | g | ASTM D1922 | 10.1 | 13.5 | 17.1 | 23.2 | 28.7 |

| COF | Adim | ASTM D1894 | 0.22 | 0.2 | 0.19 | 0.21 | 0.19 |

| Free Shrink at 120℃ | % | ASTM D2732 | 55/60 | 52/58 | 51/57 | 50/57 | 50/55 |

| DIMENSION SPECIFCATION | |||||||

| Width | mm | 100--2000 | |||||

| Length/roll | SW (single wound) | 3200m | 2665m | 2135m | 1600m | 1335m | |

| CF (center fold) | 1600m | 1332m | 1067m | 800m | 667m | ||

Product Details

Common Standard Polyolefin (POF) Shrink Film

DMPACK-06 is an economical option with average performance. Generally this film is welcomed by price sensitive markets. It is mainly used for manual L-sealers and semi-automatic shrink wrappers. Its upgrade version is DMPACK-01. All DMPACK's shrink films have been tested by SGS according to REACH, standards etc., and meet the regulations of contacting with foods.

Hot Searches