- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000 kg

-

name:

-

Lithium Ion Battery Recycling Machine

-

Final product:

-

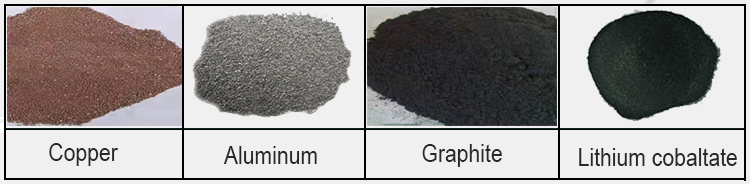

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Pow

-

Application:

-

Lithium Battery Recycle

-

Advantage:

-

High Separator Rate 99.99%

-

Color:

-

Customized Color

-

Certification:

-

CE ISO

Quick Details

-

Production Capacity:

-

300-500 kg/h(According to model)

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

FTL

-

Weight (KG):

-

1000 kg

-

name:

-

Lithium Ion Battery Recycling Machine

-

Final product:

-

Mainly Copper, Aluminum, Lithium Cobalt Oxide, Graphite Pow

-

Application:

-

Lithium Battery Recycle

-

Advantage:

-

High Separator Rate 99.99%

-

Color:

-

Customized Color

-

Certification:

-

CE ISO

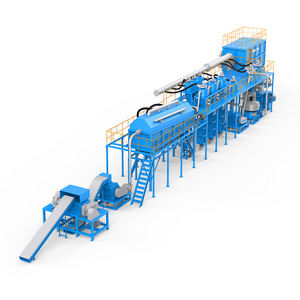

300 KG/H Used Battery Recycling Equipment Plant Lithium Ion Battery Recycling Machine

Waste lithium battery recycling and processing production line lithium battery pole piece crushing separation sorting machine ,positive electrode and negative electrode plate of waste lithium battery have certain value of recycling. Recycling these batteries can not only reduce the pollution of waste batteries to the environment, but also bring significant social and environmental benefits. In addition, the valuable components of waste lithium-ion batteries can be fully recycled and utilized, which brings huge economic benefits.

According to the structure of anode and cathode and the characteristics of component materials (copper, aluminum, cobalt powder,etc.), our company's waste lithium battery recycling plant adopts hammer vibration crushing, screening, air separation . The whole process is carried out in a sealed vacuum environment to ensure maximum recovery and no pollution. With the increase of electric vehicles and digital products, the recycling business of used lithium batteries will get better and better.

How does a lithium battery recycling plant work?

(2) By the sealing conveyor to the second crusher. (2 ~ 5 mm)

(3) The crushed material is transported into the air separator by high pressure air flow and separated into coarse powder, small powder and diaphragm. Small powder into the cyclone unloading device, coarse powder into the vibrating screen. (Air speed and pressure are precisely controlled by transducers)

(4) The material entering the rotary outflow material system is transported to the vibrating screen through the air duct, and the copper particles, aluminum particles, lithium cobalt powder and diaphragm powder separation.

(5) Coarse powder containing more metal, by high pressure air supply system transported to the vibrating screen, lithium cobalt mixed powder and copper/aluminum powder separated.

(6) The final separation system is our air gravity separator, which can completely separate lithium cobalt and copper and aluminum.

(7) The whole plant is operated under vacuum to avoid dust pollution and cobalt and lithium leakage.

final product can get from this plant:

More details about our machine:

Q: What we can recycle from waste lithium batteries?

A: You can recycle metal mixture (tin ,copper,aluminum) ,black powder (carbon, cobalt, graphite powder) and Diaphragm from waste lithium batteries

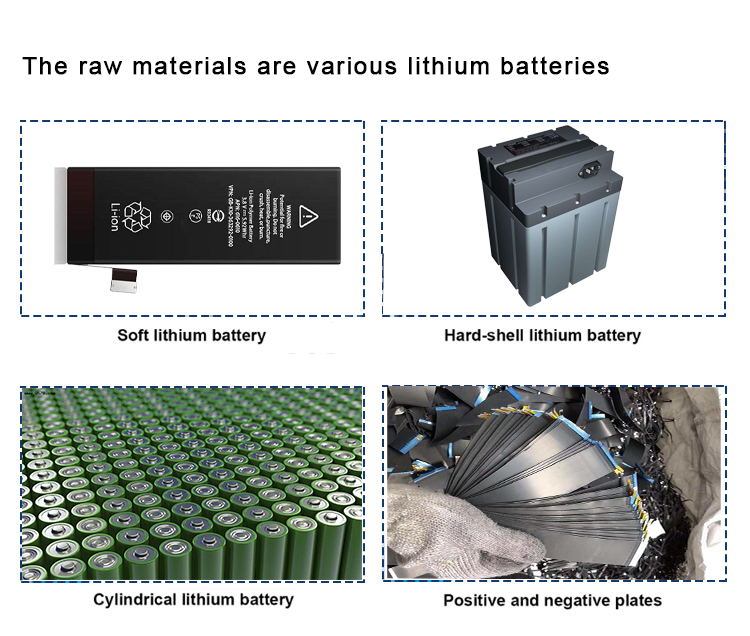

Q: What sorts of lithium batteries we can recycle through your machine?

A: Our lithium battery can recycle all kinds of lithium batteries after electric-discharge such as18650 battery,cell phone

battery, laptop battery, car lithium battery and other NCA, Alkaline battery etc.

Q: Can your company provide equipment for battery discharge?

A: Yes.We can provide not only discharge equipment but also discharge solutions base on your particular requirements

Q: I want to buy a plant of your machine,but I do not know how to install them and how to

run the entire line .could you help me ?

A:Our senior engineer will make a project drawing for your reference first.The drawing will point out the machine size/space cost. even the worker numbers suggestion.Our engineer will help to install the machine personally.

Q: What is your company's guarantee policy ?

A: All our products come with one year warranty.

Q: What can I do if the machine can not work?

A: We appreciate that if you can send us a video to show the machine situation. Our engineer will try to find out the problem and reply you soon. if it can not be solved through our guidance. Our engineer will come to your country and fix the problem personally (If the machine was broken intentionally. Sorry we will not provide the above sevices )

Q: The local environmental law is very strict. Can your machine match it?

A: Sure. All our machine had pass the CE/ISO certification

Q:My employees are not skilled at operating such machine,can you help to train them?

A: Sure.That is no problem.