- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Road, Road Basement

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WDF

-

Model Number:

-

WDF008

-

Product name:

-

Plastic Hdpe Geocell

-

Welding distance:

-

330mm-1000mm

-

Height:

-

50mm-300mm

-

MOQ:

-

500square Meters

-

Peel strength of welding point::

-

1000~1420N/10CM

-

Tensile Strength:

-

20.0Mpa

-

Surface:

-

Textured Perforated Smooth Unperforated

-

Material:

-

HDPE

-

Package:

-

Plastic Packing Belts

Quick Details

-

Warranty:

-

More than 5 years

-

After-sale Service:

-

Online technical support, Onsite Installation, Free spare parts, Other

-

Project Solution Capability:

-

graphic design, total solution for projects, Others

-

Application:

-

Road, Road Basement

-

Design Style:

-

Industrial

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

WDF

-

Model Number:

-

WDF008

-

Product name:

-

Plastic Hdpe Geocell

-

Welding distance:

-

330mm-1000mm

-

Height:

-

50mm-300mm

-

MOQ:

-

500square Meters

-

Peel strength of welding point::

-

1000~1420N/10CM

-

Tensile Strength:

-

20.0Mpa

-

Surface:

-

Textured Perforated Smooth Unperforated

-

Material:

-

HDPE

-

Package:

-

Plastic Packing Belts

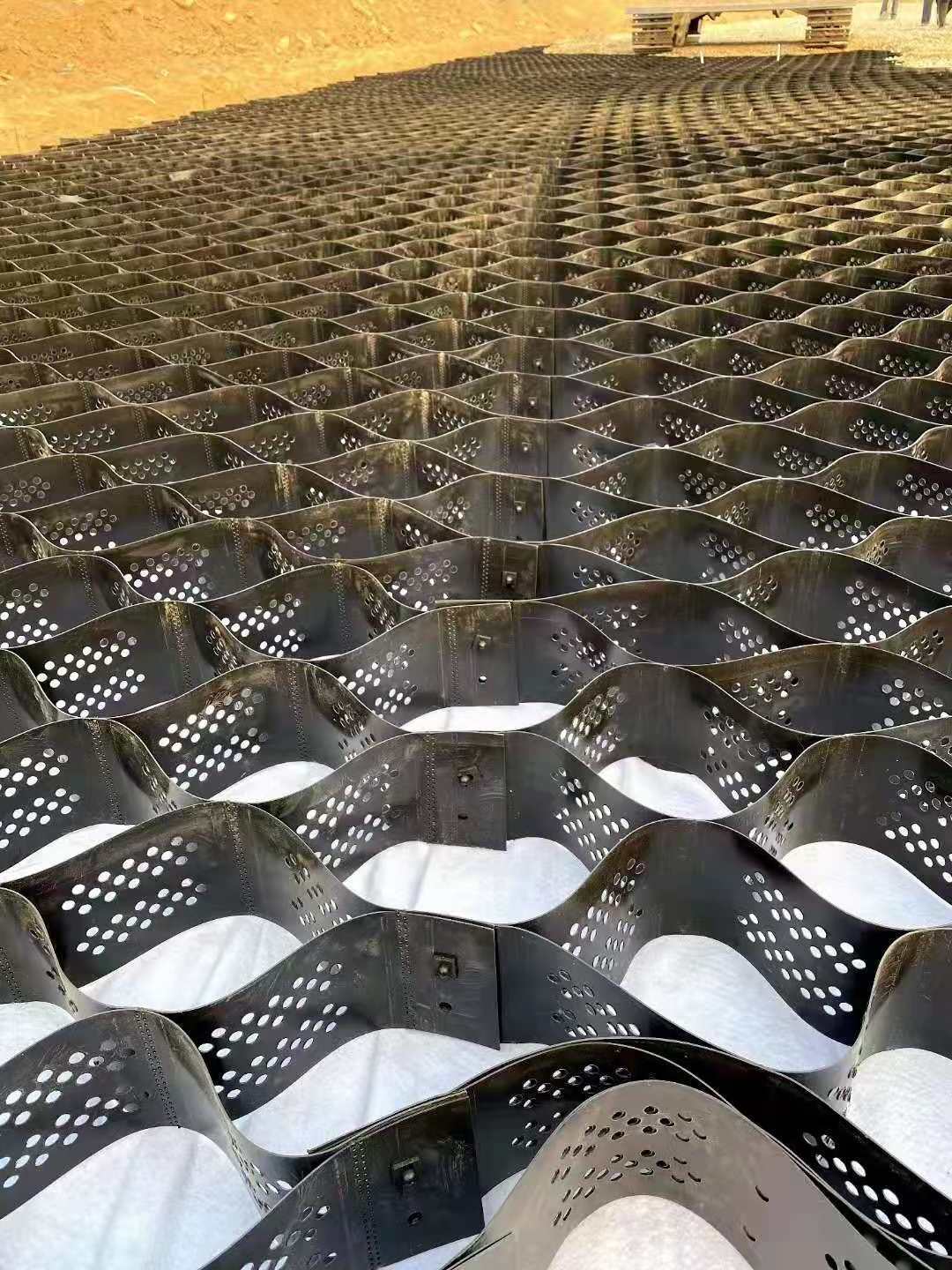

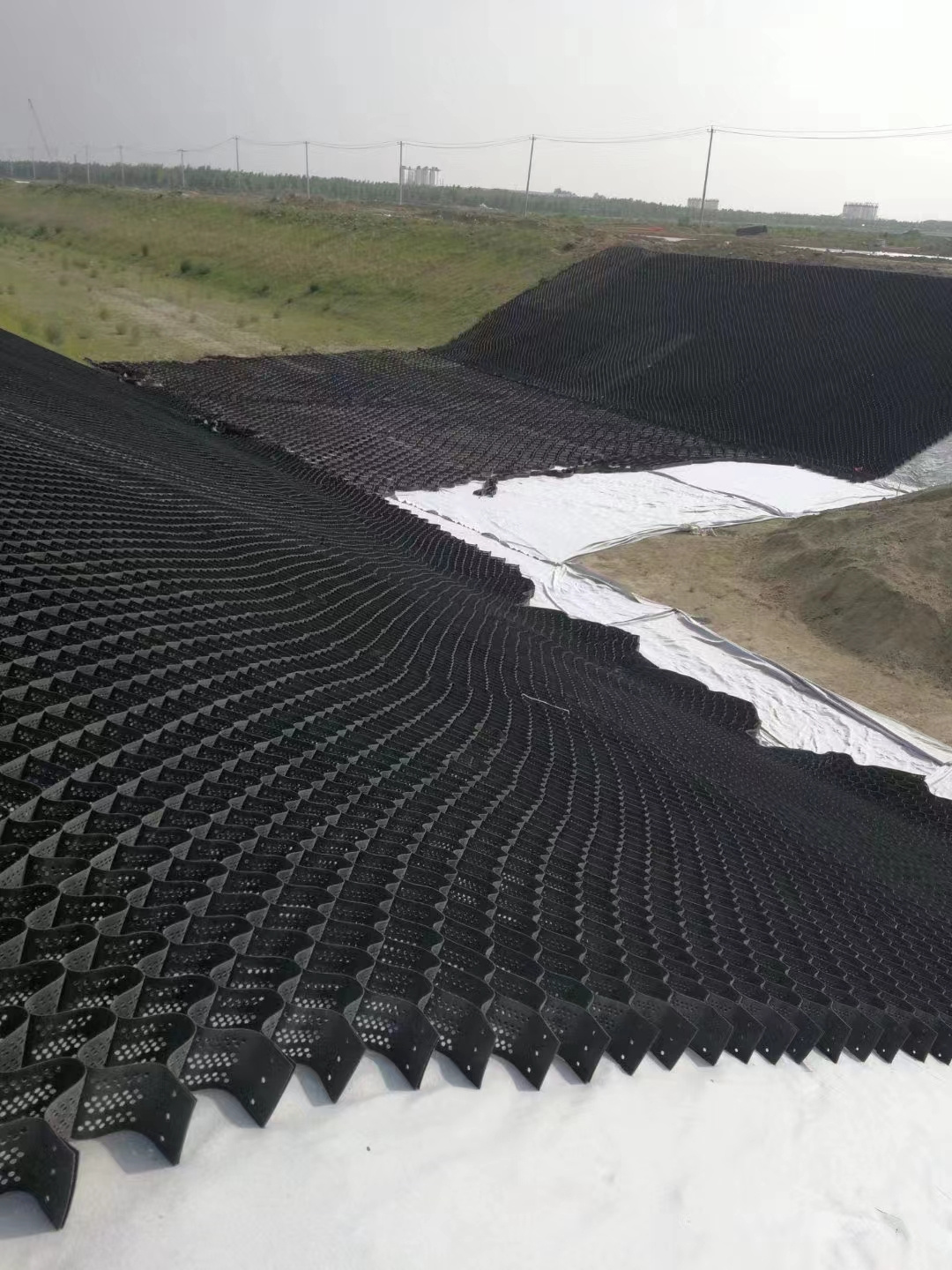

Factory manufacture customized HDPE plastic geocell grid

Product Description

Introduction

Geocell is a new type of high strength geosynthetic material which is popular at home and abroad. It is a three-dimensional

meshcell structure formed by high strength welding of reinforced HDPE sheet material.Due to engineering needs, some need to be

drilled in the diaphragm.During construction, it can be stretched into a network and filled with loose materials such as soil,

gravel,concrete, etc., to form a structure with strong lateral restrictions and large stiffness.

Main Feature:

1.It’s extractile,flexible to fold and convenient for transportation.

2.It can be filled with soil, gravel,earth,macadam and so on when being stretched into network.

3.It has light material, wear resistance, acid and alkali resistance, anti aging.

4.It is anti-skid and anti-deformation and also has a higher lateral limit, which can reduce the thickness of roadbed.

meshcell structure formed by high strength welding of reinforced HDPE sheet material.Due to engineering needs, some need to be

drilled in the diaphragm.During construction, it can be stretched into a network and filled with loose materials such as soil,

gravel,concrete, etc., to form a structure with strong lateral restrictions and large stiffness.

Main Feature:

1.It’s extractile,flexible to fold and convenient for transportation.

2.It can be filled with soil, gravel,earth,macadam and so on when being stretched into network.

3.It has light material, wear resistance, acid and alkali resistance, anti aging.

4.It is anti-skid and anti-deformation and also has a higher lateral limit, which can reduce the thickness of roadbed.

Product disply

Note:

According to different engineering requirements, we can customize sizes and colors.

Specification

|

Product Type

|

Smooth and Not Perforated

|

Smooth and Perforated

|

Textured and Not Perforated

|

Textured and Perforated

|

|

Height (mm)

|

50≤H≤250

|

50≤H≤250

|

50≤H≤250

|

50≤H≤250

|

|

Welding Distance(mm)

|

330≤A≤1000

|

330≤A≤1000

|

330≤A≤1000

|

330≤A≤1000

|

|

Thickness (mm)

|

1.0- 1.2

|

1.0- 1.2

|

1.3- 1.7

|

1.3- 1.7

|

|

Seam Peel Strength of Welding Point (N/cm)

|

≥100

|

≥100

|

≥100

|

≥100

|

|

Tensile Strength of Connection of Cells (N/cm)

|

≥120

|

≥120

|

≥120

|

≥120

|

|

Tensile Strength at Yield of Each Sheet (N/cm)

|

≥200

|

≥200

|

≥200

|

≥200

|

|

Materials Properties

|

Test method ASTM

|

UNIT

|

|

|

Cell Height

|

|

mm

|

75 100 150 200

|

|

Polymer Density

|

D1505

|

g/cm3

|

0.935-0.965

|

|

Environmental Stress Crack Resistance

|

D5397

|

Hours

|

>400

|

|

Environmental Stress Crack Resistance

|

D1693

|

Hours

|

6000

|

|

Carbon Black Content

|

D1603

|

%

|

1.5%-2.0%

|

|

Nominal Sheet Thickness Before Texturing

|

D5199

|

mm

|

1.27-5%,+10%

|

|

Nominal Sheet Thickness After Texturing

|

D5199

|

mm

|

1.52-5%,+10%

|

|

Strip Puncture Resistance

|

D4833

|

N

|

450

|

|

Seam Peel Strength

|

EN ISO 13426-18

|

N

|

1065 1420 2130 2840

|

|

Seam Efficiency

|

GRI-GS13

|

%

|

100

|

|

Nominal ExpandedCell Size (width *length)

|

|

mm

|

475*508, 500*500 etc

|

|

Nominal Expanded Panel Size (width length)

|

|

mm

|

2.56*8, 4.5*5.0, 6.5*4.5, 6.1 *2.44

|

Product Application

It is mainly used for

1.foundation reinforcement(ground stabilization:)

2.soft foundation treatment,

3.steep slope protection,

4.landslide prevention,

5.load-bearing mixed retaining wall.

6.It is especially suitable for weathering forests, sand streams and marshes.

1.foundation reinforcement(ground stabilization:)

2.soft foundation treatment,

3.steep slope protection,

4.landslide prevention,

5.load-bearing mixed retaining wall.

6.It is especially suitable for weathering forests, sand streams and marshes.

Packing & Delivery

1.PackagePacked in pallet or strength belt Or packed according to customers' requirements such as mark the company Logo (Export standard package). Packaging size and container capacity vary according to product specifications.

2.Transportion

we can package and transport the products according to the requirements of the customers. please contact us if you need.

2.Transportion

we can package and transport the products according to the requirements of the customers. please contact us if you need.

Hot Searches