- Product Details

- {{item.text}}

Quick Details

-

Plastic Type:

-

PA, PE, EVOH or PVDC/PE or PA/PE or EVA/PE

-

Place of Origin:

-

China

-

Packing:

-

Standard Package

-

Package:

-

Packaging Box

-

Printing:

-

Printing Method Applicable

-

Packaging:

-

Wound Roll Packed

-

Key words:

-

Vacuum Sealers

-

Keyword:

-

Plastic Wrap

-

Advantage:

-

Anti fog

-

Product name:

-

Shrink Wrap Stretch Film

-

Grade:

-

FOOD GRADE AND GRADE

Quick Details

-

Industrial Use:

-

Food

-

Bag Type:

-

Shrink Bag

-

Feature:

-

Barrier

-

Plastic Type:

-

PA, PE, EVOH or PVDC/PE or PA/PE or EVA/PE

-

Place of Origin:

-

China

-

Packing:

-

Standard Package

-

Package:

-

Packaging Box

-

Printing:

-

Printing Method Applicable

-

Packaging:

-

Wound Roll Packed

-

Key words:

-

Vacuum Sealers

-

Keyword:

-

Plastic Wrap

-

Advantage:

-

Anti fog

-

Product name:

-

Shrink Wrap Stretch Film

-

Grade:

-

FOOD GRADE AND GRADE

Different barrier materials pros and cons:

PVDC:good oxygen barrier and moisture barrier ability, chloride can generate toxic gas.

EVOH:good oxygen blocking property and water vapor barrier property,easy to moisture absorption and poor heat sealability.

PA:good oxygen insulation ability and mechanical attribute,poor water blocking attribute.

PET/PEN:high oxygen and water barrier, high price.

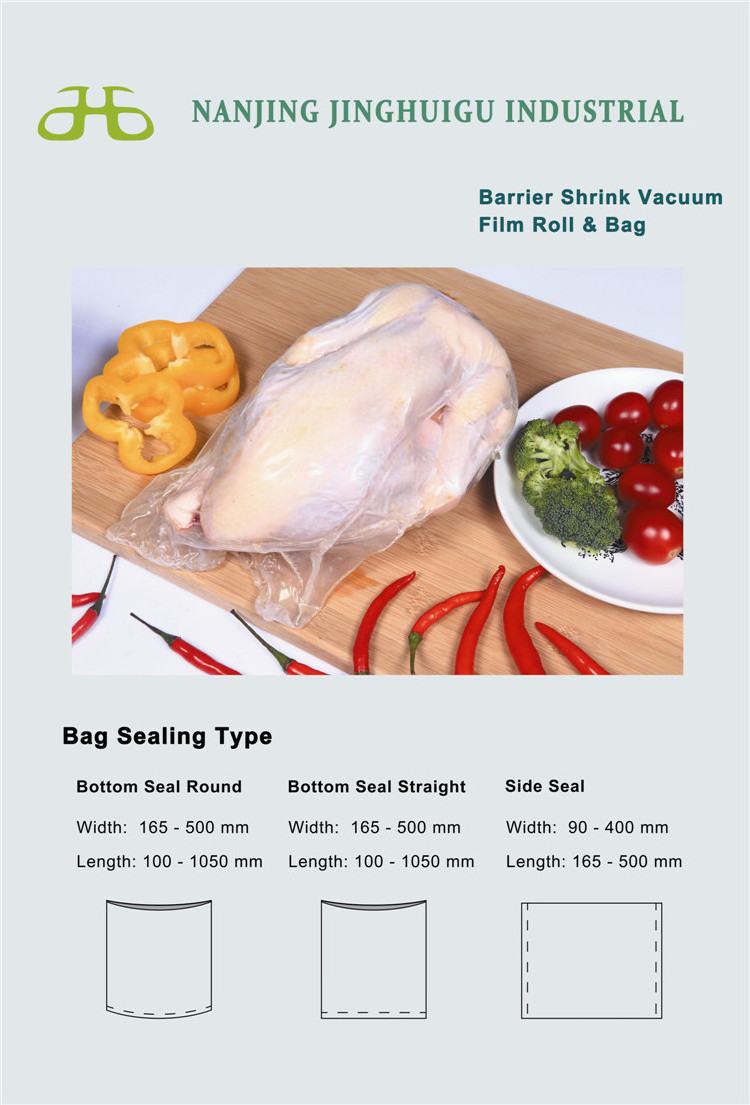

JHG Barrier Shrink bag

JHG's barrier shrink bags are based on PA/PE or EVOH materials. They are available of different sizes for a wide range applications and packaging requirements. All shrink films have been tested by SGS according to REACH standards etc., and meet the regulations of contacting directly with foods.

|

SERIES |

MODE |

BARRIER LAYER |

CHARACTERISTIC |

APPLICATION |

|

A Series heat shrink bag&film |

HRLD01 |

PA RESIN |

Excellent oxygen barrier and water vapor barrier. OTR<38ml/m2,atm;WVTR<10g/m2,atm. High strength and abuse resistance. Shrinkage rate is 26%-30%(90°C,2S). |

High-breath cheese,tuna loin,processed meat,frozen bone-in beef,mutton,pork |

|

HRLX01 |

EVOH,PA RESIN |

Excellent oxygen barrier and water vapor barrier. OTR<10ml/m2.atm;WVTR<10g/m2,atm. High strength and anti resistance, Shrinkage rate is 30%-40%( 90°C,2S). |

Mid-breath cheese,processed meat,ham,sausage. |

|

|

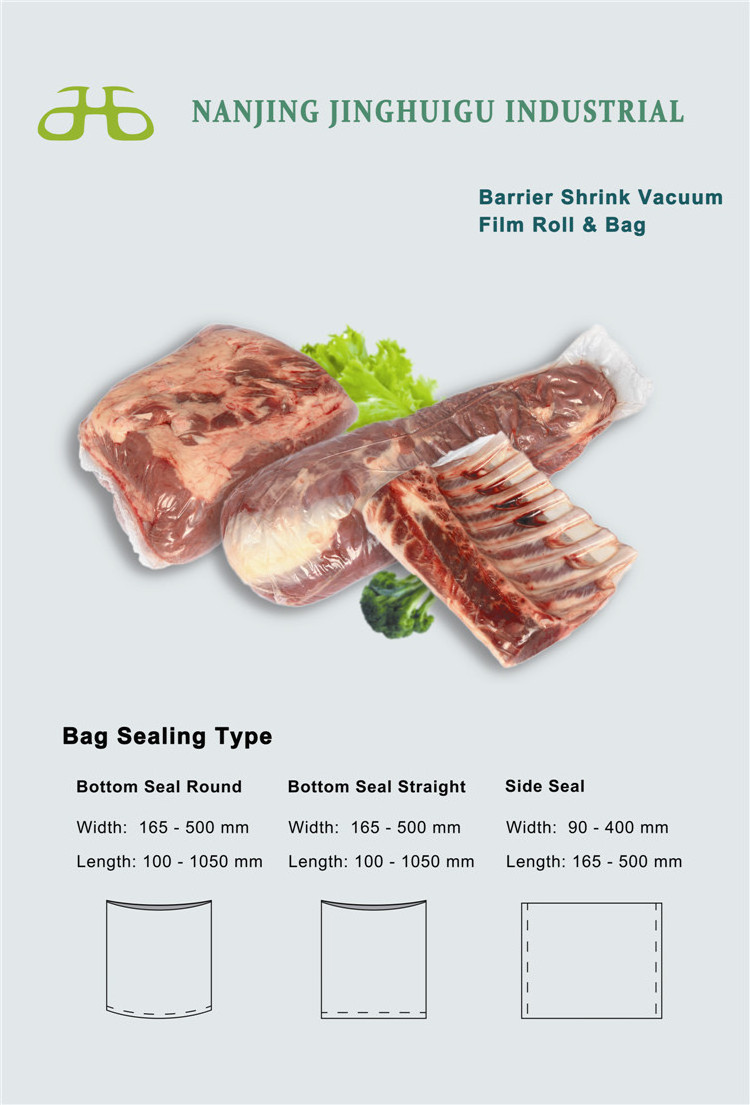

HRLD02 |

PA resin |

Excellent oxygen barrier and water vapor barrier. OTR<10ml/m2,atm;WVTR<10g/m2,atm.High Tensile strength,anti-resistance and tear propagation properties,Shrinkage rate is 30%-40%(90°C,2S). |

Heavy weight fresh bone-in beef,mutton,pork,can bear 50kgs Max. |

|

|

HRLX02 |

PA resin |

Specialized for beef,mutton & sheep & lamb brick type meat, a ideal substitution for traditional vacuum bag and film,77% higher abuse resistance and anti-break rate,more flexible,can bear 38 ℃, Puncture proof,anti-damage under low temperature,more cost effective. |

Specialized for beef,mutton brick type meat,a ideal substitution for traditional vacuum bag. |

|

|

Back seam casing |

HRC |

EVOH,PA Resin |

High oxygen barrier and water vapor barrier,Applied to poly-clip automatic sealing/clipping machine.Improved production efficiency. |

Non meat adhesive,sausage. |

|

HRC |

All kinds of ham,sausage. |

Web Sites: http://www.jhgpacking.com

Application:

1. Iced Meat, Poultry, Processed and Smoked Meat Packaging

Moisture can be maintained to prevent the loss of fresh water and color from becoming darker.

Prevent fat from oxidation, decay and changing it's fresh color.

Vacuum packaging and cold storage can improve the curing process of the meat, making the taste more juicy.

To keep apart from oxygen to maintain the natural color of fresh meat for more long time.

2. Cheese Packaging

The lower shrinkage temperature make it more suitable for products such as cheese which need the less temperature. It looks more attractive for the character of transparency and luster.

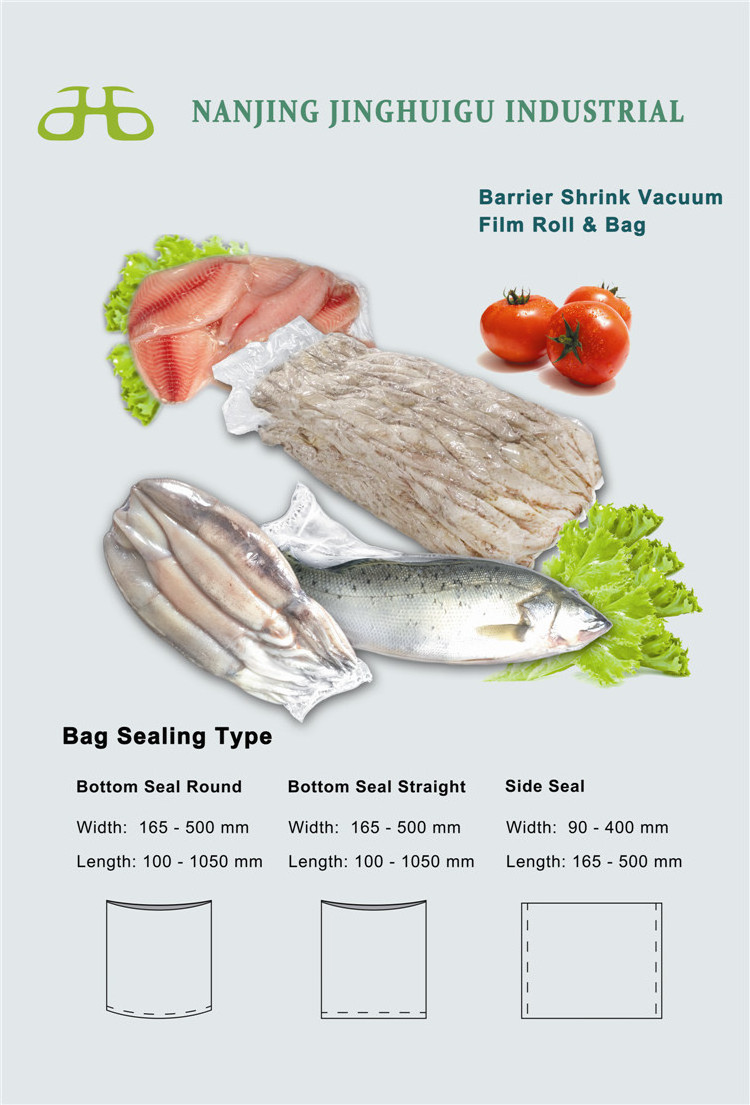

3. Seafood Packaging

Oxygen can be blocked and inhibiting the propagation of aerobic bacteria. Vacuum-packed while storage at a low temperature ( below 4℃ ) can inhibit the reproduction of anaerobic bacteria , which ensure the food healthy.

Q1: Are you trading company or manufacturer ?

A1: We are manufacturer and have the export license.

Q2: Do you provide samples ? is it free or extra ?

A2: Yes, we could offer the sample for free charge but the cost of freight is not on our account.

Q3: How long is your delivery time?

A3: Generally it is 4-7 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q4: How to pay for your goods?

A5: By L/C or by T/T (30% deposit before production, 70% balance before loading into the container).

Q5: Can I print on pof shrink film?

A5: Our company have different colors printing machine. We can print it according to your requirements!

Q6: How can I choose the right shrink film range for my product?

A6: Please tell us your products and other related information,the detailed the better. we will provide the exact packaging solution for you.

Jane Zhu

Nanjing Jinhuigu Industrial

http://www.jhgpacking.com

Tel: 86 25 83171150 Fax: 86 25 86200095

Cell& WeChat & Whatsapp:+86 13043728756