- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Liondi

-

Oil volume:

-

1.8L

-

Gasoline capacity:

-

37L

-

Fuel consumption:

-

3-4L/h

-

Laseremission system:

-

Shuangpo tansmiterJapaneseTopcon

-

Laser receiving system:

-

German Komec receiver

-

Laser control system:

-

Danfoss LaserControl System

-

Vibration palte width:

-

25.25cm/29.55cm

-

Leveling thickness:

-

680 tires 0.50-3.00cm

-

Walking speed:

-

0-55m/min

Quick Details

-

Weight:

-

900 kg, 900kg

-

Engine Brand:

-

HONDA

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Liondi

-

Oil volume:

-

1.8L

-

Gasoline capacity:

-

37L

-

Fuel consumption:

-

3-4L/h

-

Laseremission system:

-

Shuangpo tansmiterJapaneseTopcon

-

Laser receiving system:

-

German Komec receiver

-

Laser control system:

-

Danfoss LaserControl System

-

Vibration palte width:

-

25.25cm/29.55cm

-

Leveling thickness:

-

680 tires 0.50-3.00cm

-

Walking speed:

-

0-55m/min

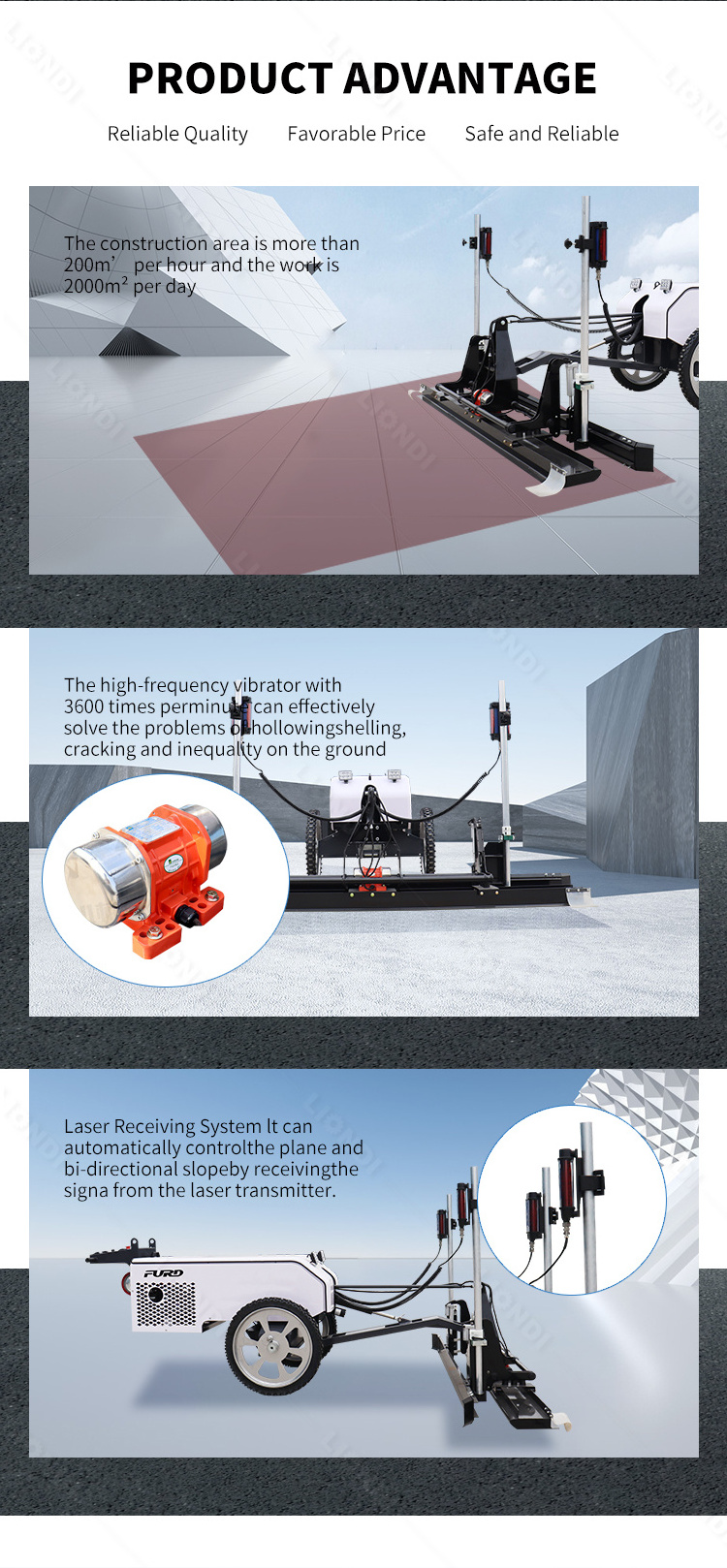

Products Description

Factory Price Concrete Manual Laser Screed Wheel Laser Screed For Sale

Liondi laser guided concrete screed mainly used in large area concrete construction, such as workshop, supermarket, warehouse, airport, playground and so on. This laser screed can satisfy the construction requirement of large area and high planeness and levelness.

laser screed flooring

Main Features concrete screeding machines

1. Used high accuracy laser device, close loop control technology and precision integrated hydraulic system, and microcomputer automatic control.

laser screed flooring

2. Screed assembly is hydraulic controlled. Integrated with laser system and computer control system, the machine will self-level and finish the screeding work with high efficiency.

3. The laser transmitter which measures the elevation is independent located, so there is no worry about the accumulative error. Compared with the traditional way, the construction joints will be greatly reduced, so the maintenance cost and slab use will be down greatly.

laser screed flooring

4. The flat and dual slope can be fully automatic controlled by the transmitter. For the complex floor which has high requirement for drainage, the 3-D floor processing system can be used.

5. The forward-seated operation can widen operator vision, reduce the labor intensity and improve working efficiency.

laser screed flooring

6. Steering, forward and reverse of the machine are all controlled by the integrated handles. Operation buttons and controller which are located on the one side of the seat, is user-friendly.

las

er screed flooring

Product Display

Product Paramenters

Product Details

Hot Searches