- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Shaoxiong Inflatable

-

Model Number:

-

NU-36

-

Size:

-

Customized

-

Packing:

-

strong pvc bags for goods and carton for accessories

-

Color:

-

Customized

-

MOQ:

-

1 Piece

-

Product Name:

-

inflatable bull riding machine,inflatable mechanical bull rodeo

-

Warranty:

-

3 Years

-

Shipping way:

-

By Sea, By Air, By Express

-

Accessories:

-

blower,repairing kits

Quick Details

-

Type:

-

inflatable sport game

-

Material:

-

PVC Tarpaulin

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Shaoxiong Inflatable

-

Model Number:

-

NU-36

-

Size:

-

Customized

-

Packing:

-

strong pvc bags for goods and carton for accessories

-

Color:

-

Customized

-

MOQ:

-

1 Piece

-

Product Name:

-

inflatable bull riding machine,inflatable mechanical bull rodeo

-

Warranty:

-

3 Years

-

Shipping way:

-

By Sea, By Air, By Express

-

Accessories:

-

blower,repairing kits

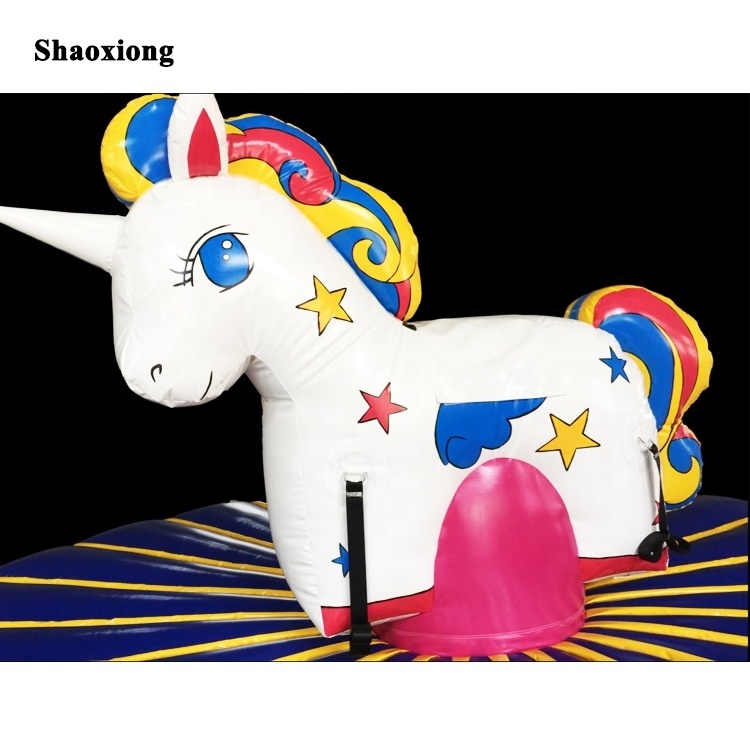

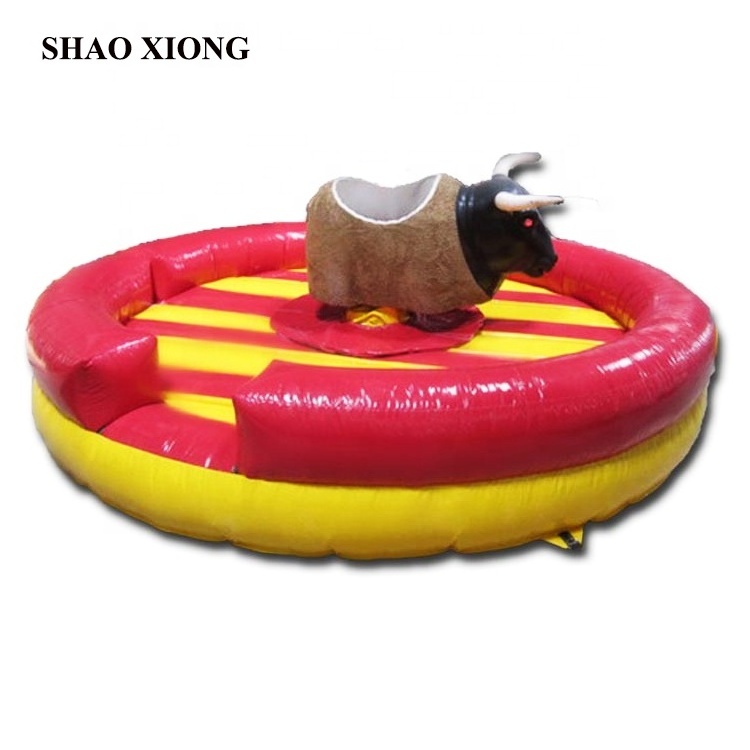

Best Selling Bull Riding Machine Customized Size Inflatable Mechanical Bull Rodeo for Kids Adults

Test out your mechanical bull skills as our sassy bull bucks and rears about. Don’t fret cowboy because when “El Toro” tires you out, there’s a soft inflatable air mattress to catch your fall! Our safe mechanical bull is perfect for the youngest buckaroo to the most experienced cowboy. Safety is always our main priority for our riders and we guarantee a safe (though certainly not smooth) ride for children and adults alike. The bull is electric and computer controlled assuring a safe and secure ride for all.

Specification for inflatable mechanical bull

Main Prtoducts

| Inflatable Water Toys | Inflatable Obstacle | Inflatable Tent | ||||

Related Inflatable Mechanibal Bull You May Like

Custom All Kinds of Inflatable Products

We have many style inflatable floating fishing mat and others,what's more,OEM could be accepted, pls send us the picture of product style you like, then we can produce it for you.

1. Product development and design

We use Rhino, CAD, CDR, Al to complete our design. Accurate to every detail (pulling ring, handle).

2.CNC cutting

High-precision CNC cutting, the data is more intuitive, more accurate, and the error is small.

3. Manual measurement

For places where machine cutting is not possible, manual measurement and cutting are used. High flexibility and easy calculation.

4.High frequency welding

Our company has mature high-frequency welding technology, and high-frequency current connects the products together. Although high-frequency welding is mostly used for metal welding, when used for PVC welding, the welded product is strong and reliable, and has strong tear resistance.

5. Hot air welding

Hot air welding is one of the main welding processes for product manufacturing. The electrodes are heated with preheated

compressed air and welded together.

6. Stitch

Needle sewing, here we use double-sided sewing procedure. Both beautiful and solid.

7. Product testing

Each product is fully tested (48 hours) before packaging.

8. Compressed air

After testing the product without defects, drain the air and compress the bundle.

9. Clean packaging

Final packaging in clean room.

We use Rhino, CAD, CDR, Al to complete our design. Accurate to every detail (pulling ring, handle).

2.CNC cutting

High-precision CNC cutting, the data is more intuitive, more accurate, and the error is small.

3. Manual measurement

For places where machine cutting is not possible, manual measurement and cutting are used. High flexibility and easy calculation.

4.High frequency welding

Our company has mature high-frequency welding technology, and high-frequency current connects the products together. Although high-frequency welding is mostly used for metal welding, when used for PVC welding, the welded product is strong and reliable, and has strong tear resistance.

5. Hot air welding

Hot air welding is one of the main welding processes for product manufacturing. The electrodes are heated with preheated

compressed air and welded together.

6. Stitch

Needle sewing, here we use double-sided sewing procedure. Both beautiful and solid.

7. Product testing

Each product is fully tested (48 hours) before packaging.

8. Compressed air

After testing the product without defects, drain the air and compress the bundle.

9. Clean packaging

Final packaging in clean room.

Related Items

EM

Packaging & Shipping

Hot Searches