- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

DH

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

5000 KG

-

Model:

-

YGM65

-

Roller Number:

-

3

-

Roller size:

-

210*150mm

-

Grind ring size:

-

650*150mm

-

Feeding size:

-

<15mm

-

Output size:

-

0.613-0.033mm

-

Powder:

-

15kw

-

Capacity:

-

0.4-1.8t/h

-

Oversize:

-

4100*3300*4500mm

Quick Details

-

Marketing Type:

-

High quality with low price

-

Capacity(t/h):

-

1-160

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DH

-

Dimension(L*W*H):

-

Customized

-

Weight:

-

5000 KG

-

Model:

-

YGM65

-

Roller Number:

-

3

-

Roller size:

-

210*150mm

-

Grind ring size:

-

650*150mm

-

Feeding size:

-

<15mm

-

Output size:

-

0.613-0.033mm

-

Powder:

-

15kw

-

Capacity:

-

0.4-1.8t/h

-

Oversize:

-

4100*3300*4500mm

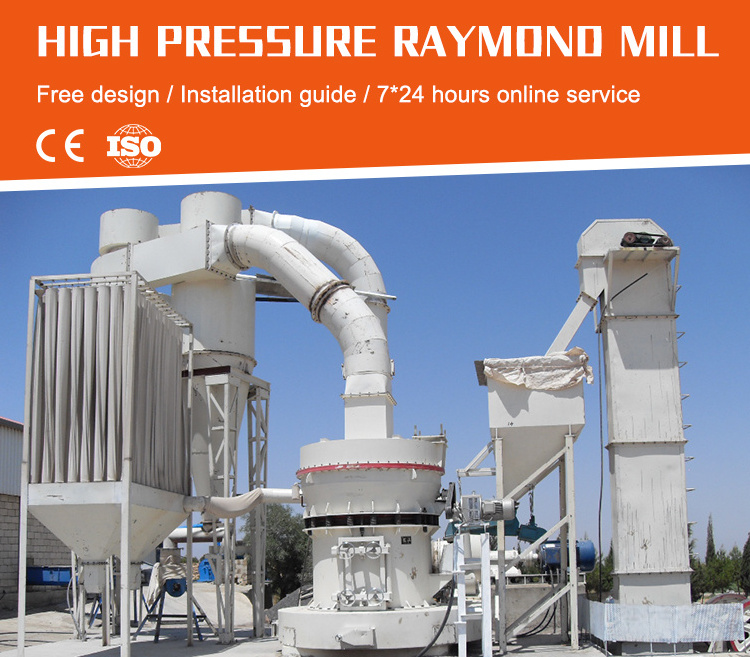

Product Description

Raymond mill is a commonly used industrial milling equipment, suitable for processing non-flammable and non-explosive ores with Mohs hardness not exceeding 7 and humidity below 6%, such as barite, calcite, potassium feldspar, talc, marble, limestone, ceramics, glass, etc. It is also suitable for milling of more than 200 kinds of materials in mining building materials, chemical industry, metallurgy and other industries. The grinding particle size can be adjusted in the range of 80-400 mesh.

Parameter

|

Model

|

The roller

|

|

|

The ring

|

|

Max

Feeding Size (mm) |

Discharge Size (mm)

|

Motor Power

(KW) |

Capacity (T/h)

|

|||

|

|

No.

|

Diameter (mm)

|

Height (mm)

|

Diameter (mm)

|

Height (mm)

|

|

|

|

|

|||

|

YGM65

|

3

|

210

|

150

|

650

|

150

|

15

|

0.613-0.033

|

15

|

0.4-1.8

|

|||

|

YGM75

|

3

|

260

|

150

|

780

|

150

|

15

|

0.613-0.033

|

18.5

|

1-3

|

|||

|

YGM85

|

3

|

270

|

140

|

830

|

140

|

20

|

0.613-0.033

|

22

|

1.2-4.6

|

|||

|

YGM85B

|

3

|

270

|

150

|

830

|

150

|

20

|

0.613-0.033

|

22

|

1.2-4.6

|

|||

|

YGM95

|

4

|

310

|

170

|

950

|

170

|

25

|

0.613-0.033

|

37

|

2.1-5.6

|

|||

|

YGM130

|

5

|

410

|

210

|

1280

|

210

|

30

|

0.95-0.033

|

75

|

3-9.5

|

|||

|

YGM160

|

6

|

510

|

230

|

1600

|

230

|

60

|

0.95-0.033

|

185

|

5-22

|

|||

Details images

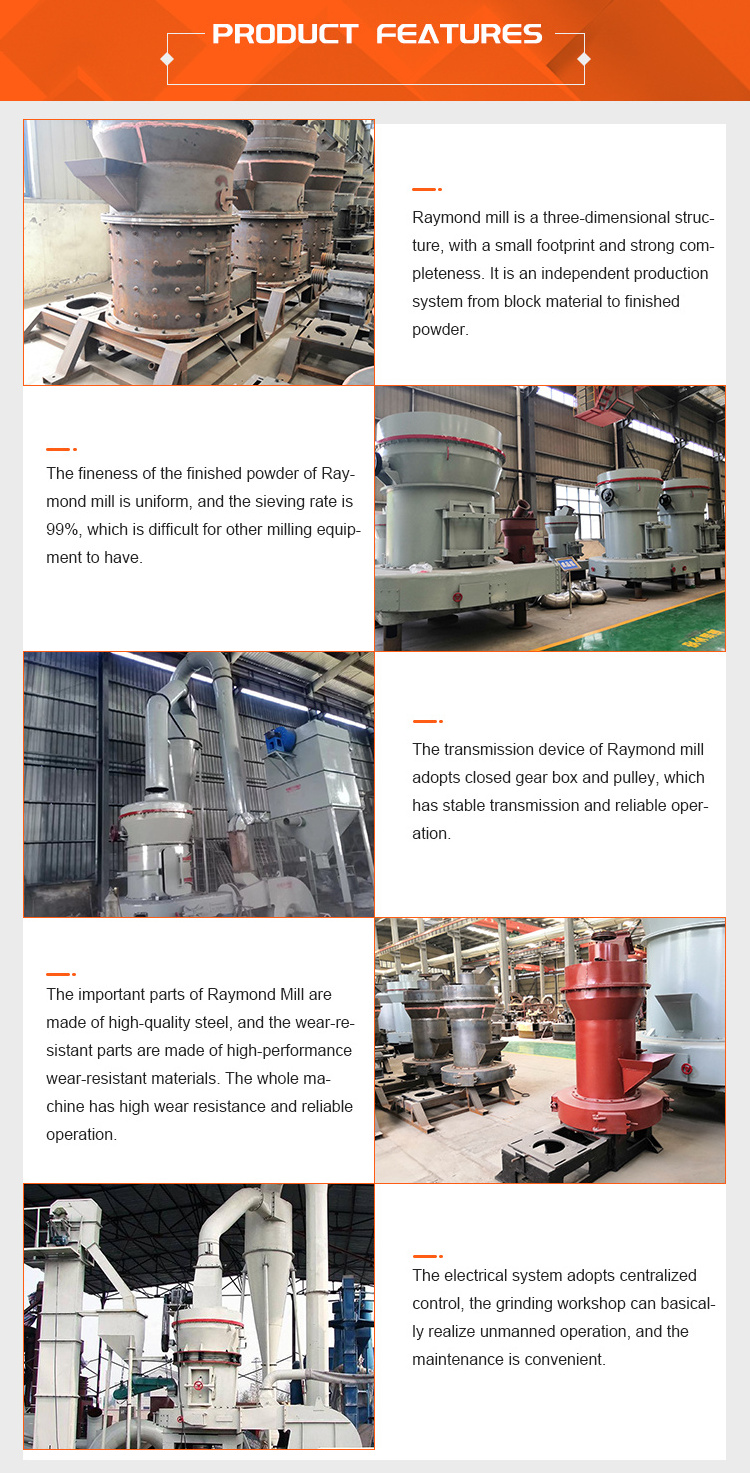

Features 1. Raymond mill is a three-dimensional structure, with a small footprint and strong completeness. It is an independent production system from block material to finished powder. 2. The fineness of the finished powder of Raymond mill is uniform, and the sieving rate is 99%, which is difficult for other milling equipment to have. 3. The transmission device of Raymond mill adopts closed gear box and pulley, which has stable transmission and reliable operation. 4. The important parts of Raymond Mill are made of high-quality steel, and the wear-resistant parts are made of high-performance wear-resistant materials. The whole machine has high wear resistance and reliable operation. 5. The electrical system adopts centralized control, the grinding workshop can basically realize unmanned operation, and the maintenance is convenient.

The complete Raymond mill machine mainly includes a grinding roller, analyzer, separator, blower, dust collector, etc. According to users’ needs, it can be equipped with a jaw/hammer crusher, bucket elevator, vibrating feeder, electric control cabinet, etc.

Hot Searches