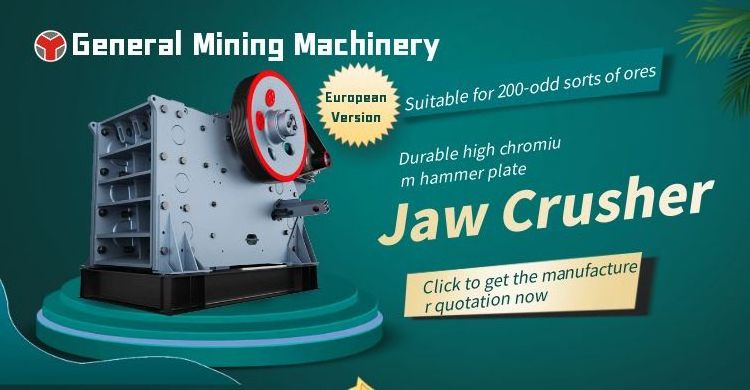

Jaw crusher is mainly used to crush kinds of mining stones primarily,and the largest compression resistance of the material to be crushed is 320MPa.easy maintenance and less operating cost. The jaw crusher is widely used in mining, metallurgical industry,building material, highway, rallway and chemical industry.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

3800*3166*3045

-

Weight:

-

58000 KG

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

Other

-

name:

-

jaw crusher

-

model:

-

PE900*1200

-

feed port size:

-

900*1200

-

max feeding size:

-

750

-

size of output:

-

95-165

-

capacity:

-

220-450

-

motor power:

-

110-132

-

overall dimension:

-

3800*3166*3045

-

weight:

-

58000

-

After-sales Service Provided:

-

Provided

Quick Details

-

Application:

-

quarry, mining, metallurgy

-

Capacity(t/h):

-

220-450T/H

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

3800*3166*3045

-

Weight:

-

58000 KG

-

Marketing Type:

-

Hot Product 2023

-

Warranty of core components:

-

Other

-

name:

-

jaw crusher

-

model:

-

PE900*1200

-

feed port size:

-

900*1200

-

max feeding size:

-

750

-

size of output:

-

95-165

-

capacity:

-

220-450

-

motor power:

-

110-132

-

overall dimension:

-

3800*3166*3045

-

weight:

-

58000

-

After-sales Service Provided:

-

Provided

Products Description

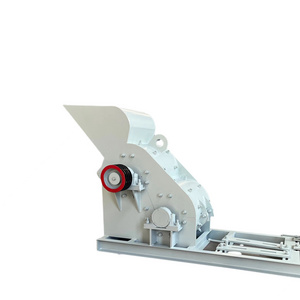

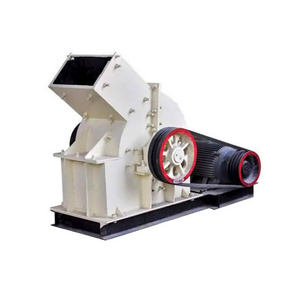

Jaw crusher

work principle

Jaw crusher cont

ains frame, eccentric shaft, big belt pulley, flywheel, side guard plate, toggle plate, back seat of toggle plate,clearance adjustable screw, reset spring, fixed jaw and movable jaw, etc. and among them the toggle plate also has insurance effect.The crushing way of this series jaw crushers is curve extruding. The motor-driven belt and belt pulley drive the removable jaw plate up and down through eccentric shaft.When the movable jaw plate moves u

p, the angle between the toggle plate and the movable jaw plate gets larger, which pushes the movable jaw plate close to the fixed jaw plate and in this procedure the materials have been squeezed, rubbed and ground; while the movable jaw plate moves down, the angle between the toggle plate and the movable jaw plate gets smaller, the movable jaw plate leaves the fixed jaw plate with forces from the pull rod and the springs and this time the ground materials will be discharged from the bottom opening of the grinding cavity. With periodic crushing and discharge of the movable plate driven by the motor,volume production is completed.

|

Model

|

Size of Feeder Opening

(mm)

|

Maximum Feeding Size(mm)

|

Discharge size(mm)

|

capacity(t/h)

|

Motor Power(kw)

|

Overall Dimension(mm)

|

Weight(t)

|

|

PE150x250

|

150x250

|

125

|

10-40

|

1-3

|

5.5

|

896x745x935

|

0.8

|

|

PE200x350

|

200x350

|

180

|

15-50

|

1-6

|

11

|

996x800x760

|

1.2

|

|

PE250x400

|

250x400

|

200

|

20-50

|

5-20

|

15

|

1430x1310x1340

|

3

|

|

PE400x600

|

400x600

|

350

|

40-100

|

15-60

|

30-37

|

1700x1732x1653

|

7

|

|

PE500x750

|

500x750

|

425

|

50-100

|

40-110

|

45-55

|

2035x1921x2000

|

12

|

|

PE600x900

|

600x900

|

480

|

65-160

|

90-180

|

55-75

|

2290x2206x2370

|

17

|

|

PE750x1060

|

750x1060

|

630

|

80-140

|

110-320

|

90-110

|

2655x2302x3110

|

29

|

|

PE900x1200

|

900x1200

|

750

|

95-165

|

220-450

|

110-132

|

3800x3166x3045

|

58

|

|

PE1000x1200

|

1000x1200

|

850

|

200-220

|

280-560

|

132-160

|

5355x4280x3050

|

69

|

|

PE1200x1500

|

1200x1500

|

1020

|

150-300

|

400-800

|

160-220

|

6380x5310x3710

|

100.9

|

|

PEX150x250

|

150x250

|

125

|

10-40

|

1-3

|

5.5

|

800x700x800

|

1.5

|

|

PEX150x750

|

150x250

|

125

|

18-50

|

5-16

|

15

|

896x745x935

|

3.8

|

|

PEX250x750

|

250x750

|

210

|

25-60

|

15-30

|

22-30

|

1667x1545x1020

|

5

|

|

PEX250x1000

|

250x1000

|

210

|

25-60

|

15-50

|

30-37

|

1550x1964x1380

|

7

|

|

PEX250x1200

|

250x1200

|

210

|

25-60

|

20-60

|

37-45

|

2192x1900x1950

|

8.5

|

|

PEX300x1300

|

300x1300

|

250

|

20-90

|

16-105

|

55

|

2720x1950x1600

|

15.6

|

PE series jaw crusher!

PEX series jaw crusher!

Features

1. Large capacity and uniform granularity.

2. Low maintenance costs and reliable safety.

3. Low operation costs with energy-saving system.

4. Discharge size can be adjusted.

2. Low maintenance costs and reliable safety.

3. Low operation costs with energy-saving system.

4. Discharge size can be adjusted.

Application

It is mainly used in the field of metallurgy, building materials, chemicals, mining and such mineral materials for grinding process. This mill can grind materials with Mosh hardness below 9.3 and humidity below 6%, various non-flammable mineral

materials,such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth,marble,ceramics,bauxite,manganese ore, iron ore,copper-ore, phosphate rock, iron oxide red, Zircon sand, slag and so on.

materials,such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth,marble,ceramics,bauxite,manganese ore, iron ore,copper-ore, phosphate rock, iron oxide red, Zircon sand, slag and so on.

Process Of crusher line

The material from the silo is uniformly and continuously sent to jaw crusher through the vibrating screen feeder for preliminary crushing, reaching the size that can be fed through the impact crusher, and sending it uniformly and continuously to the feed port of the impact crusher through the conveyor belt for secondary crushing, the qualified materials are divided into different sizes after vibrating screening, and the unqualified materials are sent back by the conveyor belt to impact and crusher again.

CLICK HERE,LET US TALK MORE DETAIL

Please give us the following details about your needs,We will give you professional advice.

1.raw materials

2.feeding size

3.discharge size

4.capacity

5. ...

1.raw materials

2.feeding size

3.discharge size

4.capacity

5. ...

Our Customers Site

Customize solutions according to customer requirements!

We are able to design and manufacture complete crusher plants with capacity from 30tph to 500tph, and to provide optimum and most economical solutions according to customers' requirements on stone specifications, output, application, etc.

This is our stone production line in Indonesia!

The customer's requirements:

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

Equipment configuration: 2xZSW490*130 vibrating feeder, 2 PE750x1060 jaw crusher, 2xPYD2200 cone crusher, 2x3YZS2460 vibrating screen, a VSI1140 sand making machine.

raw material: marble, capacity: 400 tons/hour, finished products: 0-5mm, 5-16mm, 16-31mm.

This is our stone production line in Philippine!

The customer's requirements:

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

raw material: limestone, capacity: 100 tons/hour, finished products: 0-5mm, 5-10mm, 10-20mm.

Equipment configuration: ZSW380x96 vibrating feeder, PE600x900 jaw crusher, PF1214 impact crusher, 3YZS1860 vibrating feeder.

This is our stone production line in Bolivian!

The customer's requirements:

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

Raw material: grinite, capacity: 500 tons/hour, finished products: 0-10mm, 10-20mm, 20-30mm.

Equipment configuration: ZSW6000X1300 vibrating feeder, PE1000x1200 jaw crusher, 2 sets HP500 cone crusher, 4 sets 4YZS2470 vibrating screen.

This is our stone production line in Vietnam!

Raw material: Barite, capacity: 40 tons/hour, finished products: 0-8mm, 8-15mm, 15-25mm.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Equipment configuration: ZSW320x90 vibrating feeder, PE400x600 jaw crusher, PYB900 spring cone crusher, 3YZS1237 vibrating screen.

Packing & Shipping

The package of all equipment is accord with the standard protective measures.The packing is suitable for short and long distance transportation. The moisture proof, quake proof, protected against dampness, and rustproof protection measures were taken to ensure the machine shipping to customers safely. All the machine will be packaged by plastic film.

Plastic film packaging

Large items will be wrapped in plastic film, such as jaw crusher, impact crusher, cone crusher, main mill, pipe, etc.

Box wooden packing

Small parts will be packed in wooden box, such as bolts, rubber sleeves, springs, etc

Hot Searches