- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Metal Casting Machinery

-

Name:

-

Casting Moulding Machine

-

Molding machine:

-

Foundry casting Machine

-

Application:

-

Joit moulding machine

Quick Details

-

Place of Origin:

-

China

-

Voltage:

-

110-600V

-

Weight:

-

Customized

-

Product name:

-

Metal Casting Machinery

-

Name:

-

Casting Moulding Machine

-

Molding machine:

-

Foundry casting Machine

-

Application:

-

Joit moulding machine

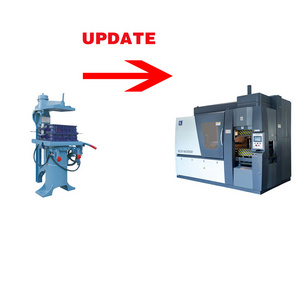

CE Certification Z146 Metal Casting Machinery / Jolting Casting Moulding Machine

Introduction :

Optimal design of the structure, the fuselage of the machine adopt the square chest and frame structure, so it can significantly increase the rigidity of the fuselage! The machine adopt the jolting technology, so it can significantly increase the compressive stress to make the hardness up to HB90 and upgrade one level about the surface roughness, so it can guarantee the quality The shock part of the machine is buffer spring, so it can effectively reduce the impact to foundation The pattern drawing mechanism adopt the cylinder,crank, connecting rod, synchronizing shaft to achieve the synchronism The control part, it adopts all pneumatic components to achieve the global function, simple operation and convenient to maintenance ;The machine is convenient to operate, itcan visual the sand mould, human operation, so it is effective to increase the productivity.

Specification of Z146 Jolting Casting Moulding Machine:

|

Type |

Z14 6 W |

|

Maximum dimension of foundry flask (mm) |

600*500 * 200 |

|

Worktable size (mm) |

700*550 |

|

Air pressure(Mpa) |

0.6 |

|

Compressive stress (kgf) |

7000 |

|

Jolting load (kgf) |

300 |

|

Compress process(mm) |

1 60 |

|

Moulding process (mm) |

200 |

|

Distance from compacting platform to worktable(mm) |

3 50-450 |

|

Distance from compressive platform to floor (mm) |

800 |

|

Productivity (box/h) |

40-60 |

|

Free air consumption (M 3 /b o x) |

0.4 |

|

O verall size(length*width*height)(mm) |

1 400*1000*1700 |

Product features:

1. This machine is used for the single box molding of single-sided board of small casting pieces in batch production, and can be used for making upper box or lower box

2. The machine adopts the spring micro-vibration compaction mechanism, and the design of shock force and pressure strength is relatively large, so it can meet the requirements of size:

6

00*

5

00

*200mm

sand box without pre-shock, and the sand mold is compact and even; It can improve casting quality.

3. The airway system is simple, easy to operate, flexible, easy to use, repair and maintenance.