- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DSN5025

-

Application:

-

Heat dissipation

-

Product name:

-

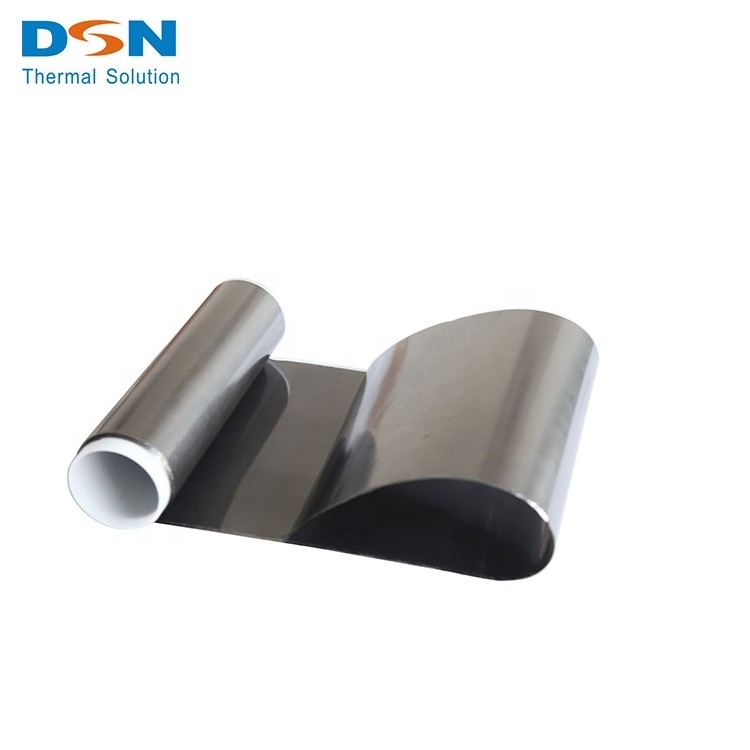

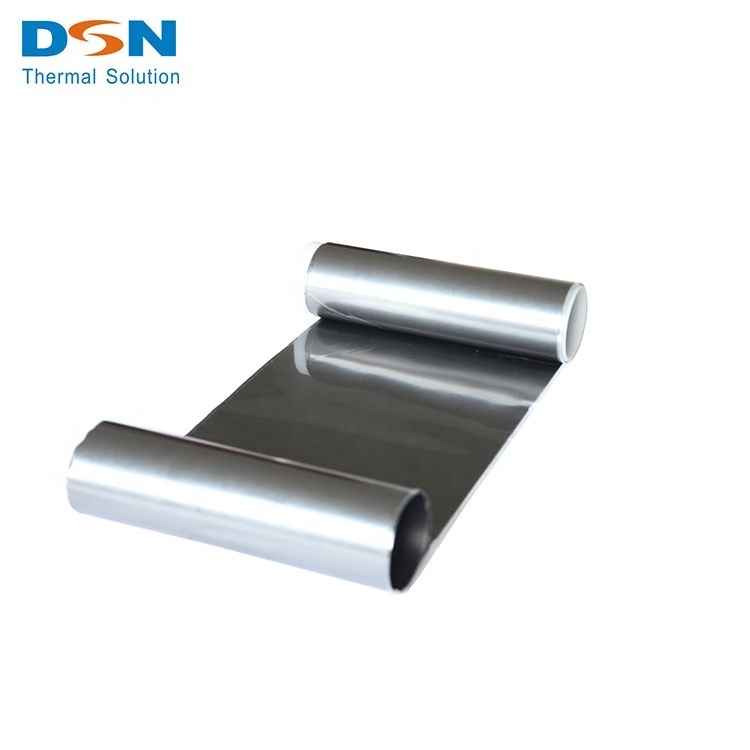

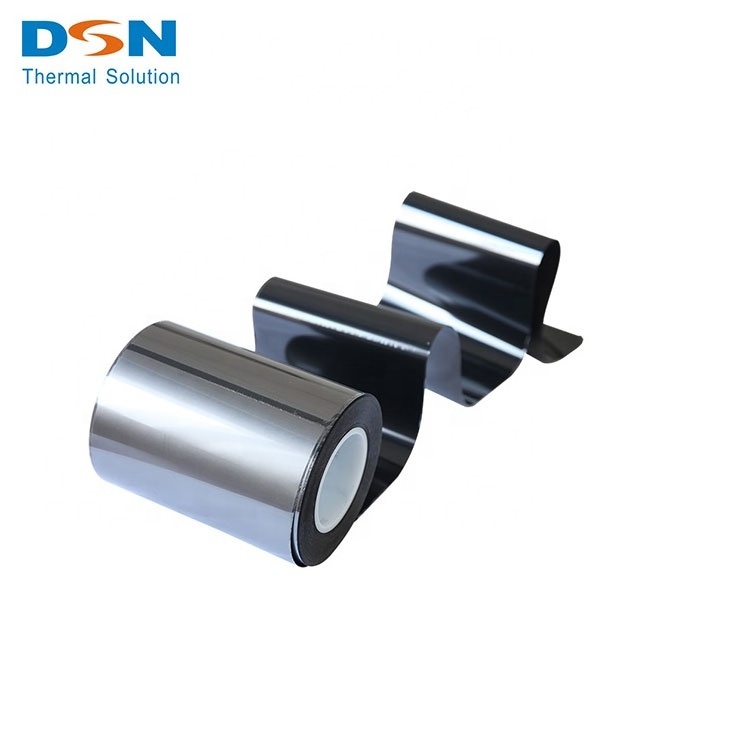

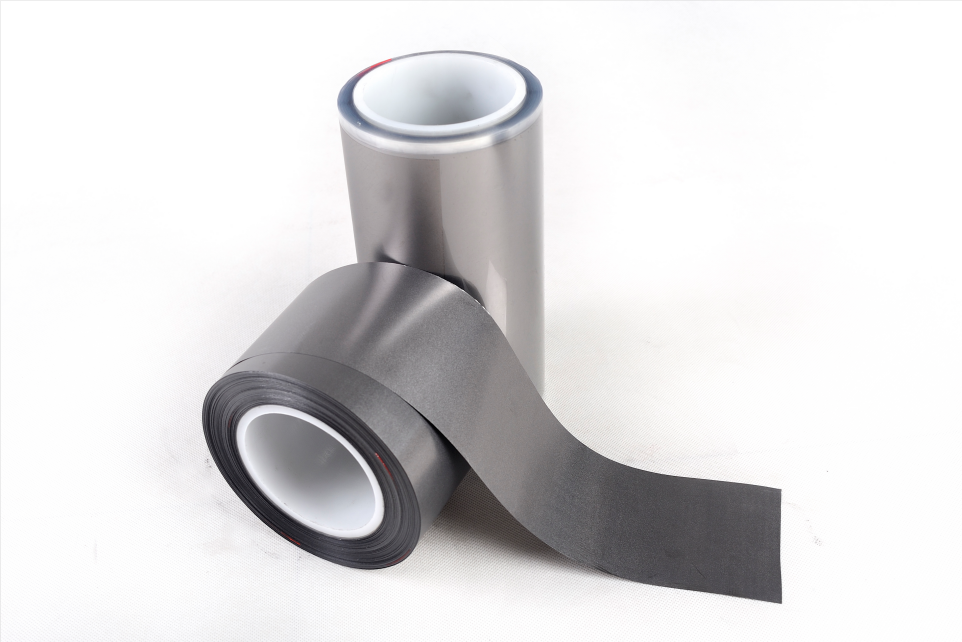

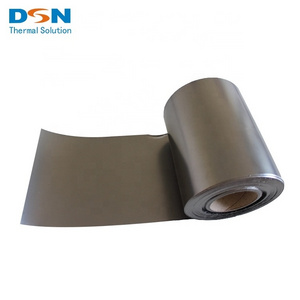

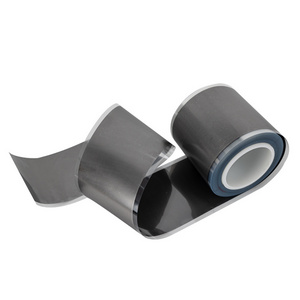

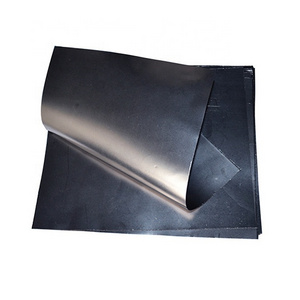

Graphite sheet

-

Material:

-

High Pure Graphite

-

Thickness:

-

25um

-

Thermal conductivity (X-Y-axis):

-

1400~1600w/mk

-

Density:

-

>2g/cm3

-

Color:

-

Black Gray

-

Shape:

-

Shape Requested

-

Size:

-

Size Requested

-

MOQ:

-

1SQM

Quick Details

-

C Content (%):

-

99.7%

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

DSN

-

Model Number:

-

DSN5025

-

Application:

-

Heat dissipation

-

Product name:

-

Graphite sheet

-

Material:

-

High Pure Graphite

-

Thickness:

-

25um

-

Thermal conductivity (X-Y-axis):

-

1400~1600w/mk

-

Density:

-

>2g/cm3

-

Color:

-

Black Gray

-

Shape:

-

Shape Requested

-

Size:

-

Size Requested

-

MOQ:

-

1SQM

|

Product Name

|

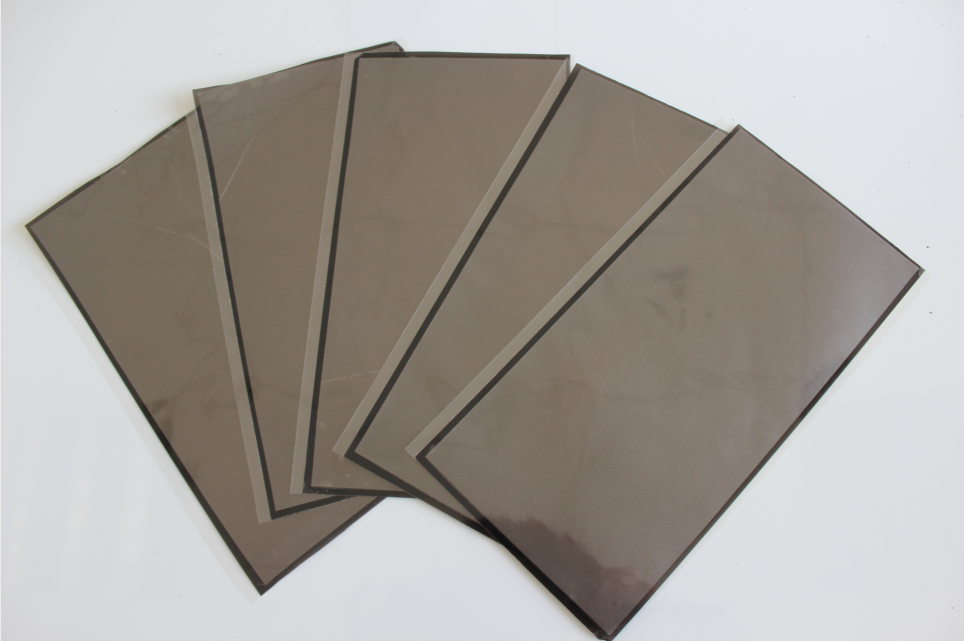

Pyrolytic graphite sheet

|

|

Material

|

Polyimide film

|

|

Function

|

Heat dissipation

|

|

Package

|

According to customer requirements

|

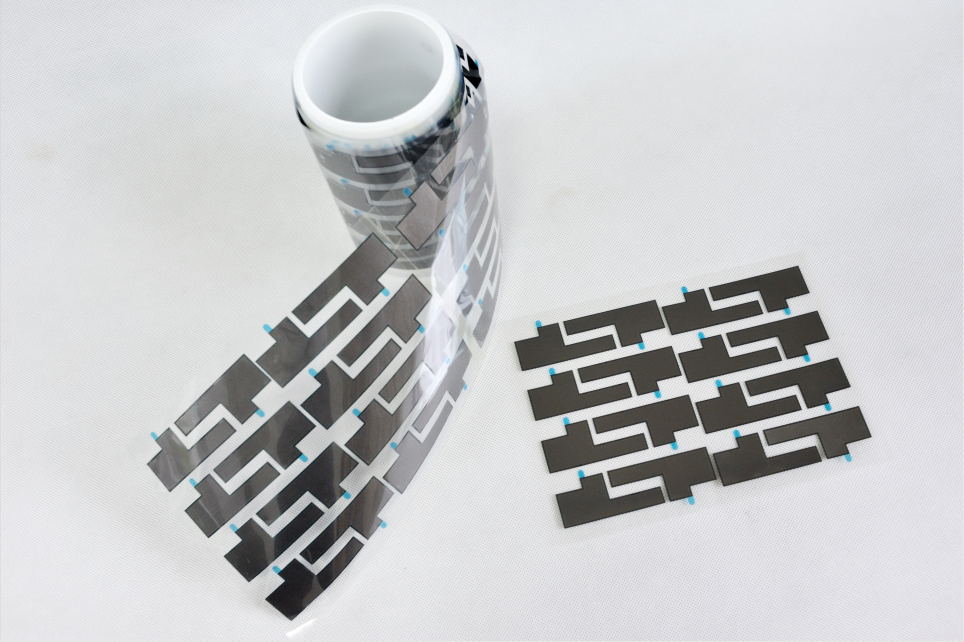

Carbon die cut graphite sheet

Parameters of pyrolytic graphite sheet

|

Thickness

|

|

DSN5017

|

DSN5025

|

DSN5032

|

DSN5040

|

DSN5050

|

|

|

|

|

0.017±0.003mm

|

0.025±0.003mm

|

0.032±0.004mm

|

0.04±0.005mm

|

0.05±0.005mm

|

|

|

Thermal

conductivity |

X-Y axis (w/m.k)

|

1700~1900

|

1700~1850

|

1550~1750

|

1450~1650

|

1400~1600

|

|

|

|

Z axis

(w/m.k) |

10~15

|

12~18

|

12~18

|

13~19

|

15~22

|

|

|

In-plane Thermal Diffusivity(mm²/s)

|

|

920~1040

|

930~1010

|

890~1010

|

880~1000

|

850~970

|

|

|

Density (g/cm³)

|

|

2.1±0.1

|

2.10±0.10

|

2.00±0.1

|

1.90±0.1

|

1.90±0.1

|

|

|

Heat capacity (J/g/K)

|

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

|

|

Operation temperature (℃)

|

|

-40~400

|

-40~400

|

-40~400

|

-40~400

|

-40~400

|

|

|

Bending (angle180, R5)

|

|

20000

|

20000

|

20000

|

20000

|

20000

|

|

|

Thickness

|

|

DSN5060

|

DSN5070

|

DSN5080

|

DSN5090

|

DSN5100

|

|

|

|

|

0.06±0.006mm

|

0.07±0.007mm

|

0.08±0.008mm

|

0.09±0.009mm

|

0.1±0.01mm

|

|

|

Thermal

conductivity |

X-Y axis (w/m.k)

|

1350~1550

|

1200~1400

|

1200~1400

|

1100~1300

|

1000~1200

|

|

|

|

Z axis

(w/m.k) |

15~22

|

15~22

|

15~22

|

15~22

|

15~22

|

|

|

In-plane Thermal Diffusivity(mm²/s)

|

|

840~960

|

830~970

|

810~950

|

790~930

|

770~920

|

|

|

Density (g/cm³)

|

|

1.85±0.1

|

1.70±0.1

|

1.70±0.1

|

1.60±0.1

|

1.50±0.1

|

|

|

Heat capacity (J/g/K )

|

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

0.87±0.01

|

|

|

Operation temperature (℃)

|

|

-40~400

|

-40~400

|

-40~400

|

-40~400

|

-40~400

|

|

|

Bending (angle180, R5)

|

|

20000

|

20000

|

20000

|

20000

|

20000

|

|

1. By courier, like DHL, UPS, FEDEX, etc. It is door to door, usually it takes 3-5 days to arrive at destination.

2. By air to the airport, usually 5-7 days.

3. By shipping, usually, it will spend 15-30 days to arrive at customer factory.

Dasen Culture

Corporate vision: lead innovation and services, help customers create competitiveness.

Natural graphite is sintered with flake graphite and earthy graphite, and its carbon content reaches 99% ~ 99.99%. Oriented film: Graphite film using advanced technology to make high-purity graphite materials to regular orientation structure

Thermal conductive silicone pad is specially designed for the purpose of high performance thermal conductivity.

Pad standard size 400mm*200mm according to customer needs to cut the shapes. Basic thickness: 0.3 mm / 0.5mm/1mm/1.5mm /

2mm

/ 3mm

.

Graphene reinforced single component precuring heat conducting gel is applied to all kinds of components with low stress requirement to make the products have high reliability. The product is self-adhesive and easily assembled.

Q1: Do you have MOQ?

A1: No MOQ for the standard product.

Q2: Do you provide samples?

A2: Yes, we do, and could delivery in 24 hours after confirmation for stock.

And we can offer free samples within one SQM. Just please pay the shipping fee.

Q3: Are you factory or trading company

?

A3: We are a professional manufacturer for over 10 years.

Q4: What is the lead time for mass production?

A4: The lead time of mass production is about 5 - 7 days.

Q5: What is your payment method?

A5: Accept TT, Paypal, West Union, L/C, ect.

Q6: Can you provide finished product processing service?

A6: Yes, we can provide the finished product after die-cutting.