- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V or 380V or 415v

-

Power:

-

10-80kw

-

Dimension(L*W*H):

-

as clients demands

-

Weight (KG):

-

5100

-

wall panel for oven:

-

75mm thick rock wool panel

-

Spraying Guns:

-

Automatic Spraying Guns

-

Control System:

-

PLC+Touch Screen Automatic

-

Heating system:

-

Electric Heating Tube

-

Function:

-

Color Paint Coating

-

certificate:

-

CE,ISO9001,ISO45001

Quick Details

-

Machine Type:

-

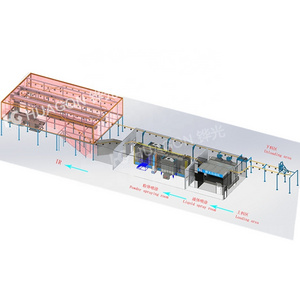

painting booth, Spray Booths, Painting Equipment, Plc Controller Programmable Logic Controller, Pre-treatment Equipment, Conveying Equipment, Drying Oven, Curing oven, Coating Equipment

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Clear

-

Voltage:

-

220V or 380V or 415v

-

Power:

-

10-80kw

-

Dimension(L*W*H):

-

as clients demands

-

Weight (KG):

-

5100

-

wall panel for oven:

-

75mm thick rock wool panel

-

Spraying Guns:

-

Automatic Spraying Guns

-

Control System:

-

PLC+Touch Screen Automatic

-

Heating system:

-

Electric Heating Tube

-

Function:

-

Color Paint Coating

-

certificate:

-

CE,ISO9001,ISO45001

Product Description

Specification

|

Spray booth size

|

2550X1500x3300mm (LXWXH)

|

|

Wall panel

|

2mm thick painted cold rolled steel sheet,Handiwork Door,Galvanized Steel Roof Panel

1 set of front door, size:600*1000mm(W*H) |

|

Air Circulation System

|

1 set of T30-6C 2.2kw axial flow fan for paint exhaust

|

|

filter system

|

Wall board made of 2.0mm cold plate,water tank made of 3.0mm cold plate, processing paint on the surface, with bolt connecting

water curtain filter or dry filter |

|

Light

|

Ceiling Light: 2 units 18w*2pcs LED lights

|

|

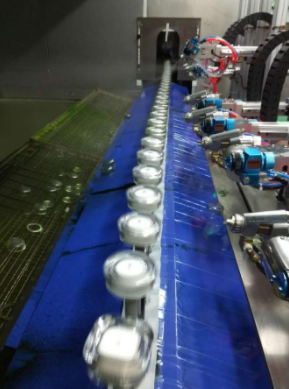

Conveyor

|

Track use special conveyor for the fit the chain,total 36m

Jig :For loading the parts,loading capacity is 6kg each,total 90pcs for the line,each 406.4mm is one jig Automatic rotating device:For automatic rotating the parts while painting,with gear motor and chain system Chain:Distance between two wheels is 50.8mm,distance between two bearing wheel is 304mm Chain wheel:Size :φ=500mm,for transmission and moving the chain Tension box for tension the whole line Driving motor:Gear motor 1 set of 2.2kw for driving the whole line,motor use TECO or better brand. Moving speed:0.3-3m/min,adjustable |

|

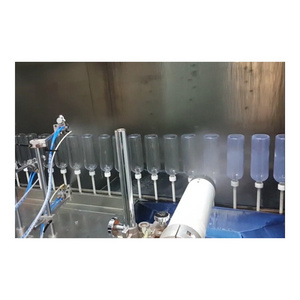

Automatic painting machine

|

Each spray booth fix with 6 sets of automatic guns,

total 12 sets of automatic guns,Japanese Anest Iwata brand |

|

Control system

|

Control system:PLC control unit,touch screen,can set program on PLC and control the whole line,use Omron brand of PLC,and

Schneider brand electric components |

|

Outside size

|

12000x1650x1400mm (LXWXH)

|

|

Inside size

|

12000x1500x550mm (LXWXH)

|

|

Wall panel

|

Rock wool steel board,75mm thick(150℃ temperature resistance),inner and outside steel board is 0.4mm thick galvanized

steel,anti-flame and heat-insulation(80℃ temperature resistance) |

|

Fan

|

2 sets of 1.1kw hot air circulation fan, each one air flow capacity:1250m3/h

|

|

Heating system

|

12units*3kw=36kw stainless steel electric heating tubes,heating temperature 50-60degree, heating time: 10-20 min(0-80degree)

|

|

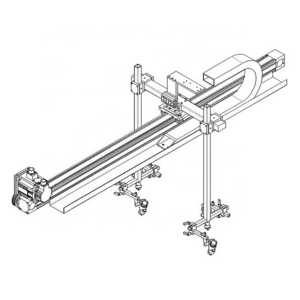

Conveyor

|

Size:15500*1300*850,supporting pillar made of 40*80*2.0mm square tube,side made of 3mm thick steel bending,driving motor is 1.5kw

gear motor,frequency conversion speed governor is 1.5kw,speed from 0-6m/min adjustable.Bottom with M16 adjustable feet,adjustable height ±50mm. |

|

Control system

|

PLC control system

|

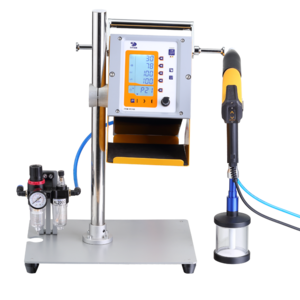

infrared light heating for oven

infrared light heating tubes for heating the oven,heating temperature from 40-60degree,temperature adjustable with temperature controller and sensor

axial flow fan for water curtain spray booth

water curtain spray booth for paint exhaust,good effect and cost less

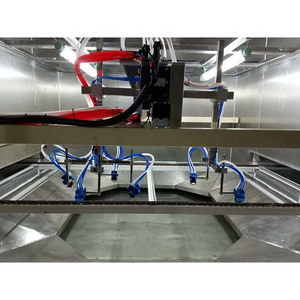

automatic paint machine

automatic paint machine with 4-8 sets of automatic painting guns for painting flat parts

Related Products

Manufacturing Technique

Welding

professional workers for welding process,to make structure of the painting line

Polishing

Polish the welding slag and make the surface flat,to prepare for the next process-powder coating

Test running

for pre-installation the whole line and test all the parts working well,debug and adjustment

Powder coating and packing

surface powder coating and packing process,waiting for loading container

Packing & Delivery

professional package with experienced loading container team,loading tight to save space and avoid damage to goods

Hot Searches