- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50Hz /Customized

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

1800*1100*2100mm

-

Marketing Type:

-

Favourable Price

-

Product name:

-

oxygen plant cost

-

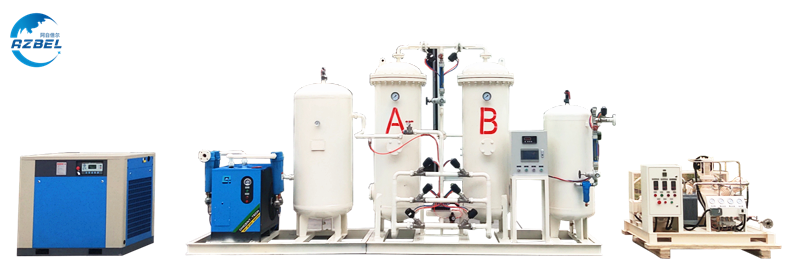

Brand:

-

AZBEL

-

Purity:

-

90%~96%

-

Keywords:

-

Medical Oxygen generator

-

Technology:

-

PSA

-

Capacity:

-

3Nm3/h-200Nm3/h

-

Start Pressure:

-

0.8MPa/1.0Mpa/Customized

-

Operation Cycle:

-

24 hours

-

Package:

-

Crate and pearl wool

-

Certification:

-

CE

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

AZBEL

-

Production Rate:

-

3Nm3/h-200Nm3/h

-

Voltage:

-

380V 50Hz /Customized

-

Weight:

-

1000 KG

-

Dimension(L*W*H):

-

1800*1100*2100mm

-

Marketing Type:

-

Favourable Price

-

Product name:

-

oxygen plant cost

-

Brand:

-

AZBEL

-

Purity:

-

90%~96%

-

Keywords:

-

Medical Oxygen generator

-

Technology:

-

PSA

-

Capacity:

-

3Nm3/h-200Nm3/h

-

Start Pressure:

-

0.8MPa/1.0Mpa/Customized

-

Operation Cycle:

-

24 hours

-

Package:

-

Crate and pearl wool

-

Certification:

-

CE

Products Description

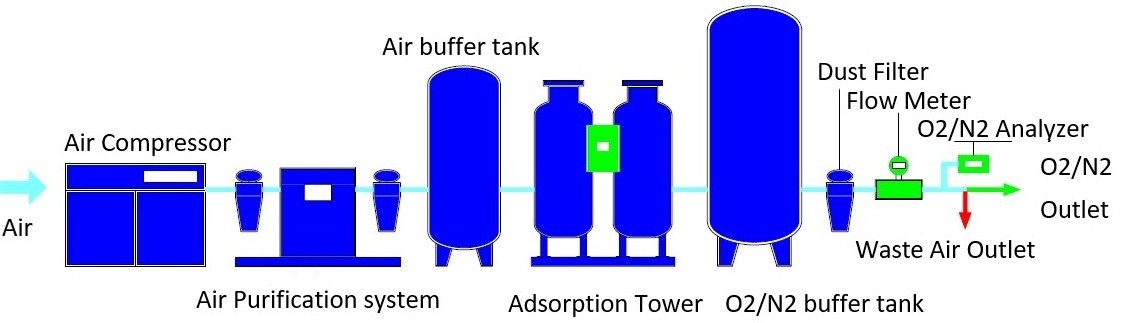

PSA oxygen generator is based on the principle of pressure swing adsorption, using zeolite molecular sieve as adsorbent, under the pressure, from the air to produce oxygen. The purified and dry compressed air is adsorbed under pressure and desorbed under pressure in the adsorber. Due to the aerodynamic effect, the diffusion rate of nitrogen in the pores of zeolite molecular sieve is much higher than that of oxygen. Nitrogen is preferently adsorbed by zeolite molecular sieve, and oxygen is enriched in the gas phase to form finished oxygen.

Then through decompression to atmospheric pressure, adsorbent desorbed nitrogen and other impurities adsorbed to achieve regeneration. Generally, two adsorption towers are set in the system, one tower adsorption oxygen production, the other tower desorption regeneration, through the plc program controller to control the opening and closing of the pneumatic valve, so that the two towers alternate circulation, in order to achieve the purpose of continuous production of oxygen.

Then through decompression to atmospheric pressure, adsorbent desorbed nitrogen and other impurities adsorbed to achieve regeneration. Generally, two adsorption towers are set in the system, one tower adsorption oxygen production, the other tower desorption regeneration, through the plc program controller to control the opening and closing of the pneumatic valve, so that the two towers alternate circulation, in order to achieve the purpose of continuous production of oxygen.

|

Product Name

|

PSA Oxygen Generator

|

|

Purity

|

93%±3%

|

|

Productivity

|

3Nm3/h~200Nm3/h

|

|

Pressure

|

0.8/1.0MpaG(Customized)

|

|

Output

|

Oxygen Gas

|

|

Material

|

Carbon Steel

|

PSA Oxygen Generator Process Flow Diagram

Application Field

Medical treatment

Mining and mineral processing

Iron and steel industry

Aerospace industry

Metal cutting welding

Chemical industry

On-site Installation

Hot Searches