- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Al 51305

-

Product Name:

-

Metal Motor Parts

-

Material:

-

Aluminum Alloy ADC12

-

Surface treatment:

-

Natural Light,Anodizing, Powder coating, Spray painting, Etc.

-

Process:

-

Mold making +Casting +Machining(if Need)+surface Treatment

-

Mould Life:

-

250000-300000shots

-

Tolerance:

-

+-0.02mm

-

MOQ:

-

1 Piece

-

Application:

-

Industry

-

Certification:

-

ISO9001:2015

-

Service:

-

OEM\ODM

Quick Details

-

Shaping Mode:

-

Die Casting

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

Die Casting Aluminum

-

Model Number:

-

Al 51305

-

Product Name:

-

Metal Motor Parts

-

Material:

-

Aluminum Alloy ADC12

-

Surface treatment:

-

Natural Light,Anodizing, Powder coating, Spray painting, Etc.

-

Process:

-

Mold making +Casting +Machining(if Need)+surface Treatment

-

Mould Life:

-

250000-300000shots

-

Tolerance:

-

+-0.02mm

-

MOQ:

-

1 Piece

-

Application:

-

Industry

-

Certification:

-

ISO9001:2015

-

Service:

-

OEM\ODM

Professional Precision Metal Motor Die Casting Aluminum Alloy Accessories Bronze Casting

|

Material |

Aluminum alloy

:

ADC12, ADC10, A360, A380, A356

, 6061, 6063

Zinc alloy : ZA3#,ZA5#,ZA8# |

|

Processing Craft |

Drawings→ mould making → die casting →rough machining → CNC machining→surface treatment →product checking→ packing →delivery |

|

Tolerance |

± 0.02mm |

|

Surface Treatment |

E lectroplating, Chrome Plating , Zinc Plating, Nickel plating, Electrophoresis, Anodization, Polishing, Sandblasting, Passivation, Powder coating , Spray painting , Etc. |

|

Quality Assurance |

ISO9001:2015 Certified, Third party testing. |

|

Quality Guarantee |

Two years |

|

Inspection |

1.Foundry in-house: 100% inspection on critical dimension; 100% on appearance.

|

|

Mainly Testing Facility |

Three-dimensional measuring instrument (CMM) , Salt spray test box, Dynamic balance detector, Pneumatic detection |

|

Features & Advantage |

1.High machining accuracy, the flatness within 0.1mm. 2.High strength and not easy to deform, has good electrical and thermal conductivity. 3.High finish appearance,smooth surface roughness is Ra1.6 after machining. 4.The machining precision is high and the assembly structure is seamless. 5.No granules, no spots and no painting peel off in appearance. 6.Smooth appearance, corrosion resistance. 7.Pass 20000 Times Wear Resistance Test. 8. Pass Salt Spray Test with 96 Hours. 9. Pass Coating adhesion Test and Scratch-proof Test. 10.Pass Adhesion Cross-Cut Test and 3M Glue Test. 11.Pass Film Thickness Test. |

|

Standard |

1.Aluminum alloy: ISO3522-84, ASTMB85-96, JISH5302:2000

, EN1706:1998

|

|

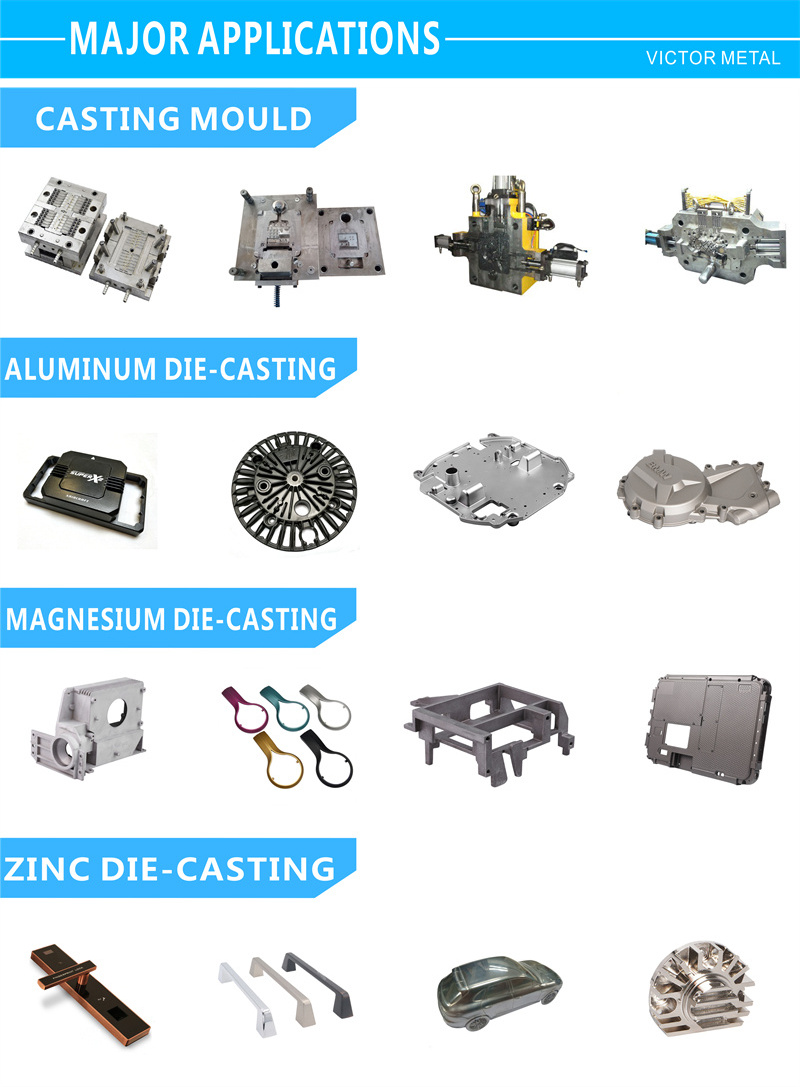

Application |

3C industry, lighting decoration, electrical appliances, auto parts, furniture parts, electric tool, medical equipment, intelligent automation equipment, other metal casting parts. |

Dongguan Victor Metal Products Co.,Ltd , is a wholly-owned enterprise specializing in the design and production of molds, die casting, gravity casting,aluminum extrusion, CNC processing parts, and stamping parts .

Our company has 14 years of production and manufacturing experience , specializing in providing a full range of production services from mold design and development to product molding and post-treatment, surface treatment.

Products are mainly used in 3C industry, lighting, electronic appliances, auto parts, furniture, bathroom, power tools, medical machinery, intelligent automation equipment and other industries. The products are exported to Europe, America and other countries.

Our company has 130 people , including 8 R & D personnel, 8 foreign trade personnel and 15 quality inspectors.

We always adheres to the business philosophy of " customer-oriented, technology and management innovation as a means, continuous improvement of service, continuous cost reduction " to seek development. No matter the size of customers, our company will continue to provide customers with accurate and perfect service. Also undertake OEM, ODM cooperation.

Q1.Are you a factory or trade company?

A:We are a factory with over 11 years.It is a wholly-owned enterprisespecializing in the design and production of molds,die casting,gravitycasting,aluminum extrusion,CNC processing parts,and stamping parts.

Q2.Where is your factory?

A:Our factory is located in Dongguan City,known as the "world factory",adjacent to Shenzhen and Hong Kong.

Q3.How to quote?

A:Received the sample or drawing in CAD/STP/IGS form then we willmake the quotation.

Q4.How about the MOQ?

A:In order to cooperate with customers to develop the market,the initialperiod is unlimited quantity,and after the development is stable,the MOQis 500pcs.If it is lower than the MOQ, each set of molds will becharged an additional 180 dollars.

Q5.Payment terms

A:Mold costs:50%prepay upon order confirmation,balance after sampleapproval,

Mass production:50%prepay,balance upon T/T available.

Q6.Delivery time

A:Normally 15-40 days depends on the order quantities.

Q7.How about the packing?

A:Standard or customized will both be available.