- Product Details

- {{item.text}}

Quick Details

-

Weight(KG):

-

10

-

Dimension for hole:

-

380*226

-

Interface:

-

USB+RS232 Communction Port

-

Port:

-

24input 24output

-

Display:

-

8 Inch Real Color LCD

-

Program:

-

User Macro Program

-

User Store Room:

-

128Mb

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Place of Origin:

-

Sichuan, China

-

Brand Name:

-

NEWKer

-

Dimension(L*W*H):

-

400*245*125

-

Weight(KG):

-

10

-

Dimension for hole:

-

380*226

-

Interface:

-

USB+RS232 Communction Port

-

Port:

-

24input 24output

-

Display:

-

8 Inch Real Color LCD

-

Program:

-

User Macro Program

-

User Store Room:

-

128Mb

-

After-sales Service Provided:

-

Video technical support

-

After Warranty Service:

-

Field maintenance and repair service

|

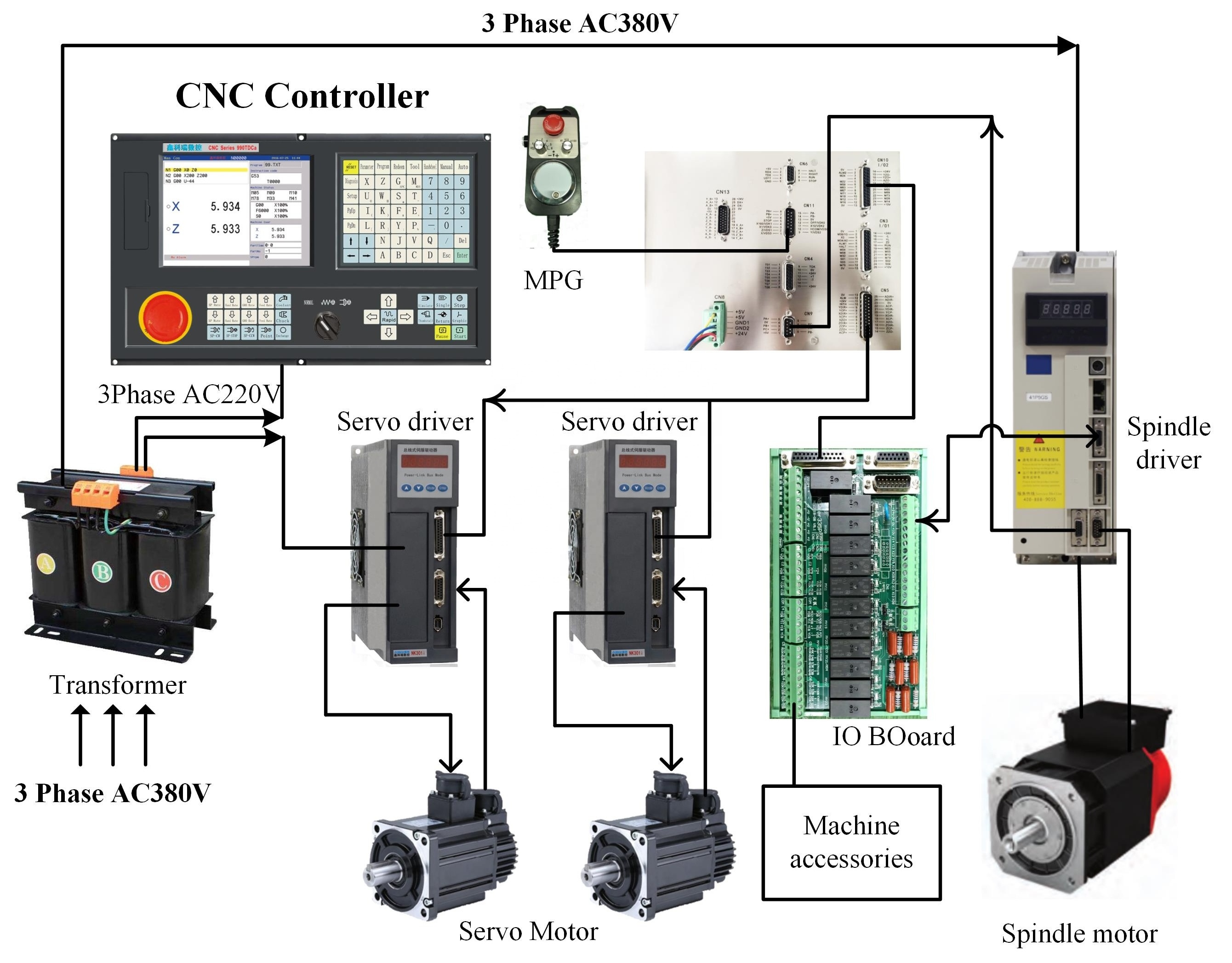

System Function

|

|

G code shows

|

|

|

number of control axis

|

3~4 (X,Y,Z,A)

|

Locate rapidly:

|

G00

|

|

The smallest programming:

|

0.001mm

|

Straight line interpolation

|

G01

|

|

The most programming:

|

Thread cut:±99999.999mm

|

Thread cut:

|

G02/03

|

|

Feed speed:

|

0.001~15m/min

|

high speed deep drilling loop

|

G73

|

|

Continuous manual:

|

one axis or two axis at the same time

|

point drilling loop

|

G81, G82

|

|

Line interpolation:

|

Straight line, arc, screw thread interpolation

|

Line cutting drilling loop

|

G73

|

|

Cutter compensation:

|

Length of the compansation、nose of tool compensation

|

Boring loop

|

G85, G86, G89

|

|

Spindle function:

|

gear、Double analog control、Rigid tapping

|

Tapping loop

|

G74, G84

|

|

Handwheel function:

|

panel、handheld

|

program loop

|

G22, G800

|

|

handwheel processing:

|

The handwheel processing function

|

local coordinate system:

|

G52

|

|

Screen protection:

|

The screen protection function

|

check skip

|

G31, G311

|

|

Communication function:

|

RS232、USB interface

|

polar programming

|

G15/16

|

|

Compensation function:

|

cutter, clearance, screw, radius compensation

|

metric and inch programming

|

G20/21

|

|

Edit program:

|

relative/absolute programming, hybird programming

|

program mode

|

G90/91

|

|

Preread function:

|

Preread 10,000 short straight lines

|

processing plane

|

G17, G18, G19

|

|

limit position function

|

hard limit, soft limit

|

workpiece coordinate system:

|

G54~G59

|

|

Password protection:

|

Multilevel password protection

|

tool length compensation

|

G43, G44, G49

|

|

Input/output:

|

I/O 24*24

|

tool radius compensation

|

G45~G48

|

|

PLC programme:

|

All open PLC design

|

C tool radius compensation

|

G40, G41, G42

|

|

Acceleration and deceleration control:

|

Straight line、Index

|

Accurate positioning/continuous path processing

|

G60/G64

|

|

Number of encoder:

|

any setting

|

returns the starting point

|

G26, G261~G264

|

|

User macro program:

|

Have

|

returns the fixed point

|

G25, G61, G60

|

|

Electrical gear function:

|

Have

|

returns the reference point

|

G28, G281~G284

|

|

|

|

delay function

|

G04

|

|

|

|

auxiliary function:

|

S、M、T

|

Hot Searches