- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

4000L

-

Weight (KG):

-

60 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUAYUE

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

Customized, Referring

-

Power (kW):

-

1.1 kW

-

Marketing Type:

-

Hot Product

-

Place of origin:

-

China(Mainland)

-

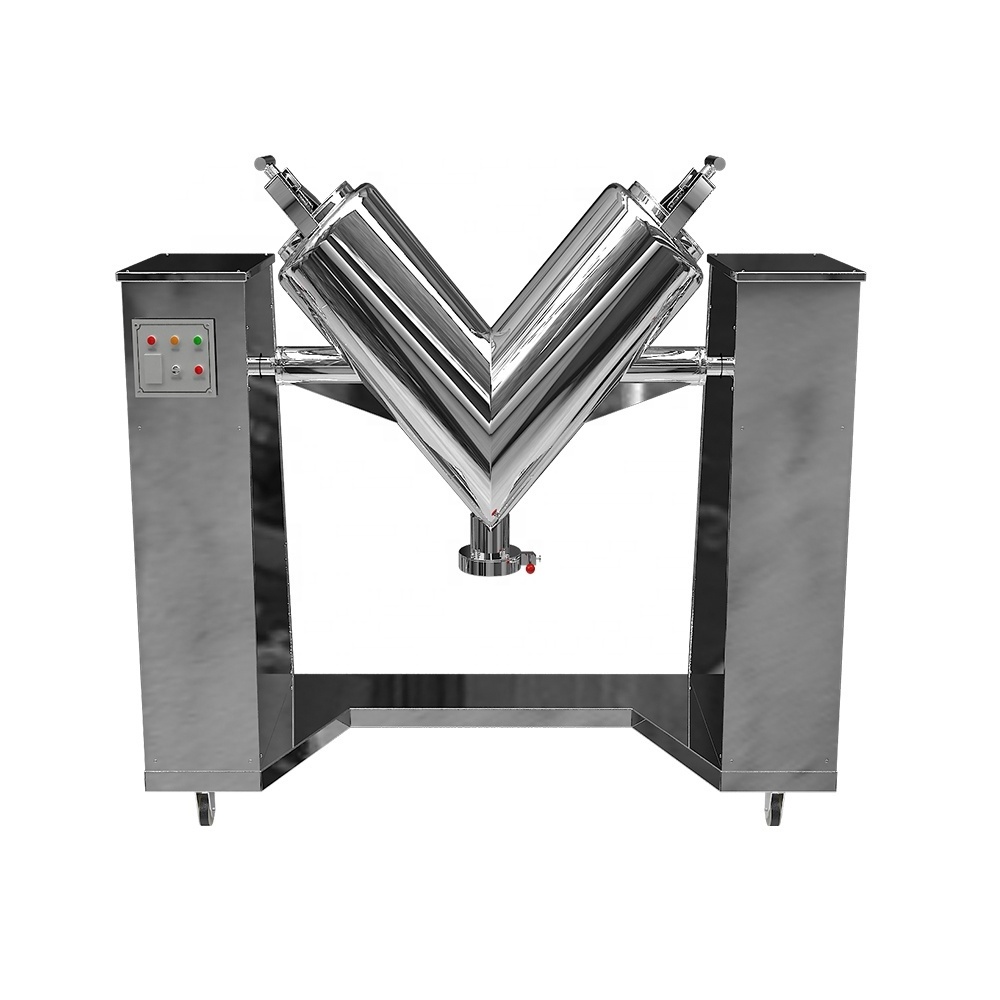

Machine Type:

-

V type

-

Max.Loading Capacity:

-

4000L

-

Function:

-

Soap powder mixing machine

-

Mixing time:

-

6-10min/time

-

Model:

-

GHJ high-efficient mixer

-

Power(W):

-

1.1-11kw

Quick Details

-

Barrel Volume (L):

-

5-4000

-

Max. Loading Volume (L):

-

4000 L

-

Range of Spindle Speed(r.p.m):

-

6 - 24 r.p.m

-

Max. Loading Capacity:

-

4000L

-

Weight (KG):

-

60 KG

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KUAYUE

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

Customized, Referring

-

Power (kW):

-

1.1 kW

-

Marketing Type:

-

Hot Product

-

Place of origin:

-

China(Mainland)

-

Machine Type:

-

V type

-

Max.Loading Capacity:

-

4000L

-

Function:

-

Soap powder mixing machine

-

Mixing time:

-

6-10min/time

-

Model:

-

GHJ high-efficient mixer

-

Power(W):

-

1.1-11kw

Product Description

Working Principle

The machine adopts gravity mixing, small pressure feed on materials, high mixing uniformity, stainless steel cylinder, inner and outer wall polishing, low power consumption, easy cleaning, vacuum butterfly valve discharging. No leakage and dust emission.

Features

Mixing barrel structure, high mixing efficiency, the barrel is made of stainless steel. The inner and outer walls are polished. It has a beautiful appearance. Mix well. It's versatile. GMP standard. The machine can mix fine powder, coagulated powder or two or more kinds of powder with moisture. Such as the addition of trace phase can also be mixed effect (refers to the addition of a small amount of ingredients mixed) . This machine is suitable for mixing dry material particles in chemical, food, metallurgy and other industries.

Specification

|

Model

|

Barrel volume(L)

|

Production capacity

(kg/per batch)

|

Mixing time

(min)

|

Power(kw)

|

Overall size(mm)

|

Weight(kg)

|

|

GHJ-5

|

5

|

2

|

3-6

|

0.37

|

560*270*560

|

50

|

|

GHJ-20

|

20

|

5

|

3-6

|

0.55

|

660*300*630

|

70

|

|

GHJ-50

|

50

|

12

|

4-8

|

0.55

|

900*380*900

|

90

|

|

GHJ-180

|

180

|

40

|

4-8

|

1.1

|

1780*680*1700

|

290

|

|

GHJ-300

|

300

|

60

|

6-10

|

1.1

|

1880*680*1700

|

300

|

|

GHJ-500

|

500

|

100

|

6-10

|

2.2

|

2500*1350*2450

|

550

|

|

GHJ-1000

|

1000

|

200

|

6-10

|

4

|

3050*1650*2700

|

850

|

|

GHJ-1500

|

1500

|

300

|

6-10

|

4

|

3343*1650*2980

|

1020

|

|

GHJ-2000

|

2000

|

400

|

6-10

|

7.5

|

3820*1900*3480

|

2040

|

|

GHJ-2500

|

2500

|

500

|

6-10

|

7.5

|

3990*1900*3540

|

2200

|

|

GHJ-3000

|

3000

|

600

|

6-10

|

7.5

|

4690*2200*4000

|

2500

|

|

GHJ-4000

|

4000

|

800

|

6-10

|

11

|

4950*2200*4230

|

2800

|

Main Features

1. Unique mixing cylinder.

2. High mixing effects.

3. No dead angle.

4. Forced agitator be added.

5. even mixing.

2. High mixing effects.

3. No dead angle.

4. Forced agitator be added.

5. even mixing.

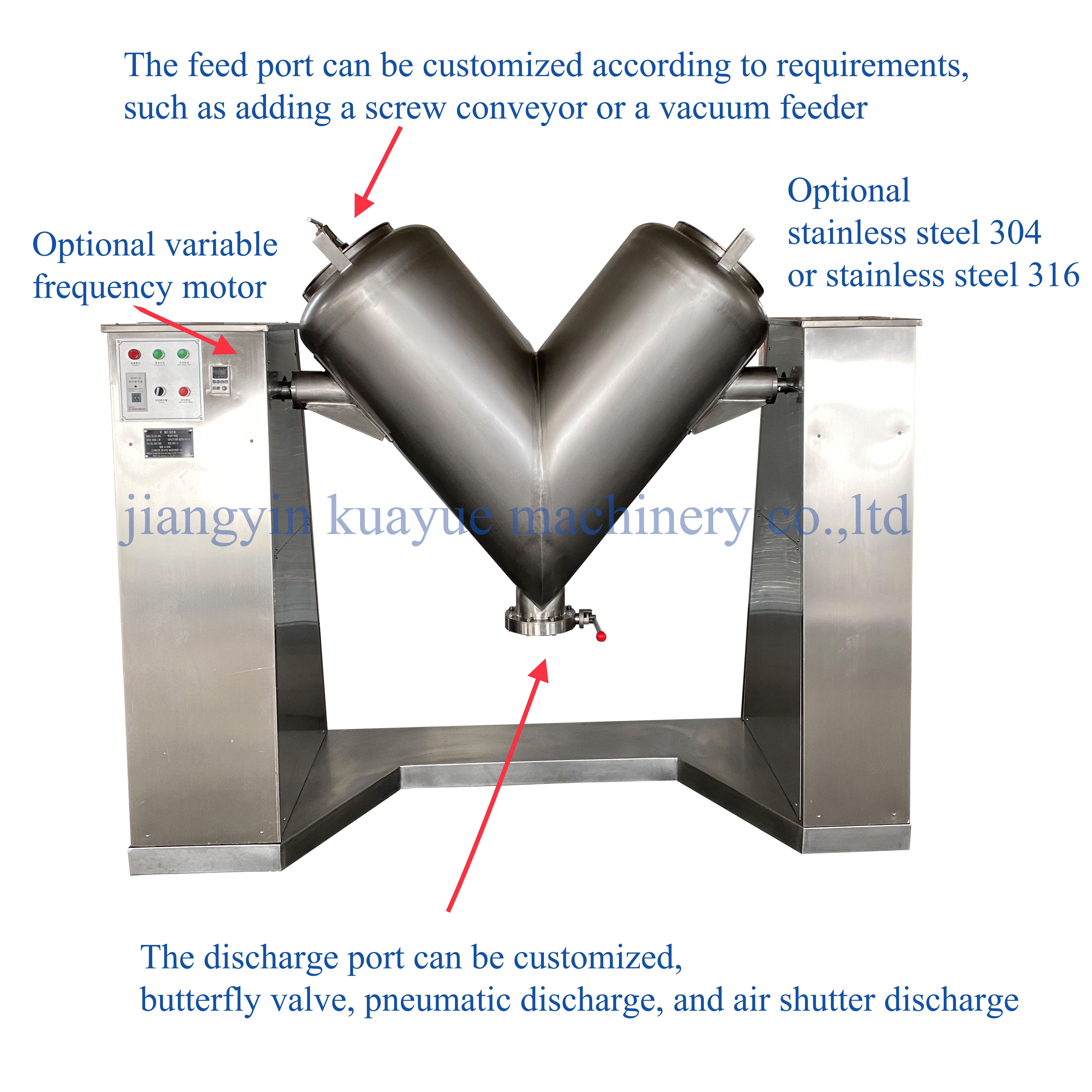

Customized

1. Customized shape

2. Customized Size

3. Choice of materials, such as SS304 or SS316

3. Choice of materials, such as SS304 or SS316

Operating procedures

1. The newly installed mixer shall be run on empty, the time relay shall be set to 5 ~ 10 minutes, before starting the mixer, the joints shall be checked whether screwed up or not, and no persons or articles shall be allowed within 500 mm from the maximum rotary diameter, just to be safe. Start the whole machine should run smoothly without abnormal vibration and abnormal noise. After the machine is stopped, try again to see if it is normal. If everything is normal, it can be put into production formally.

2. If the connection between the vacuum tube joint and the suction joint is in the form of a quick connection, just turn the suction pipe about 50 ° to tighten the clockwise direction and insert the suction pipe into the material container.

3. Start the vacuum pump, vacuum about 0.025 MPA when the start suction.

4. Suction finished should cut off the vacuum pump power supply, cut off its vacuum, so as to avoid sewage into the mixer pollution materials.

5. Remove the vacuum fitting and suction fitting and install the bonnet fitting in the same way as rule (rotate counterclockwise when dismounting) .

6. Set the working hours of the mixer according to actual needs.

7. Press the Start button only when there is no person or article in the maximum rotary diameter of the mixer.

8. When the time is up, the mixer will stop automatically. If the outlet is not in the vertical down position, press the button to make the outlet vertical down.

9. Open discharge port.

10. Clean the mixer in time according to the actual production needs.

Note: The above operation procedure is vacuum automatic loading, if no vacuum automatic loading, then omit 2,5 operation steps, first manual loading, after the closure of the valve cover can start operation.

Maintenance

1. The transmission oil should be cleaned and replaced every six months.

2. The bearing grease should be cleaned and replaced once a year.

3. Grease spur gears once a week.

4. Gas buffer tank and gas-water separation tank, depending on the mixer frequency of regular discharge, open the bottom valve.

Packing & Delivery

wooden case or container.

Hot Searches