- Product Details

- {{item.text}}

Quick Details

-

Power:

-

7.5 kw

-

Dimension(L*W*H):

-

1900 x 2700 x 1200mm

-

Weight:

-

750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cutting Speed:

-

1200mm/s - 1500/s

-

Available Materials:

-

Soft material, Corrugated paper, PVC, Acrylic, PU, Cloth, Car Mats

-

Motor:

-

Servo motor

-

Available Thickness:

-

0.4mm - 55mm

-

Cutting Ways:

-

Physical cutting

-

Functions:

-

Vibration cut, milling cut, v-cut, draw, wheel press, hobbing cut

-

Fixing Method:

-

Divisional vacuum absorption

-

Interface of Transmission:

-

Net work transmission

Quick Details

-

Voltage:

-

220, 380 ±10%

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

RUIZHOU

-

Power:

-

7.5 kw

-

Dimension(L*W*H):

-

1900 x 2700 x 1200mm

-

Weight:

-

750 KG

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Cutting Speed:

-

1200mm/s - 1500/s

-

Available Materials:

-

Soft material, Corrugated paper, PVC, Acrylic, PU, Cloth, Car Mats

-

Motor:

-

Servo motor

-

Available Thickness:

-

0.4mm - 55mm

-

Cutting Ways:

-

Physical cutting

-

Functions:

-

Vibration cut, milling cut, v-cut, draw, wheel press, hobbing cut

-

Fixing Method:

-

Divisional vacuum absorption

-

Interface of Transmission:

-

Net work transmission

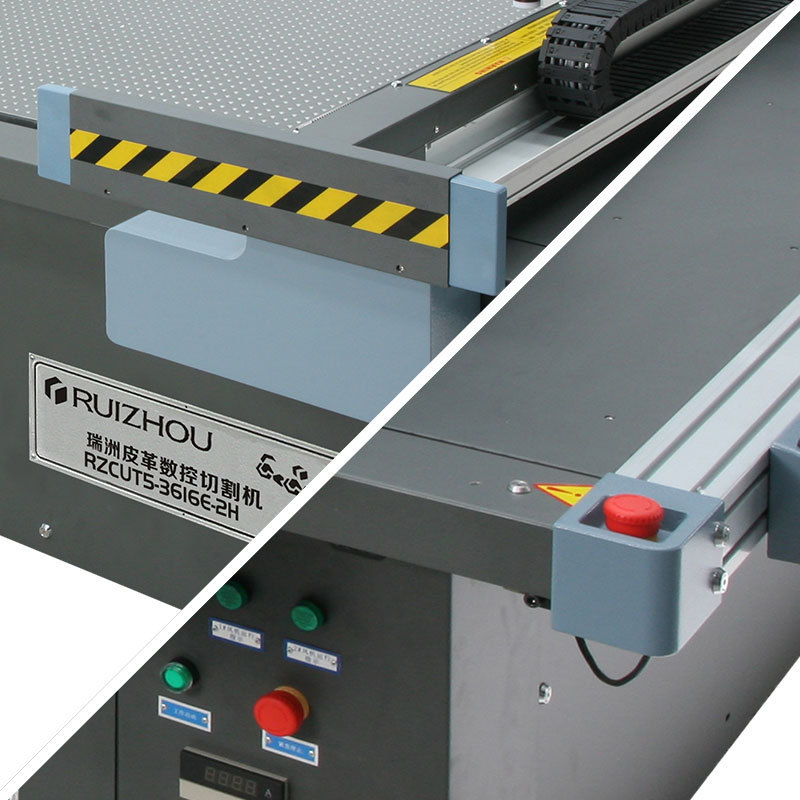

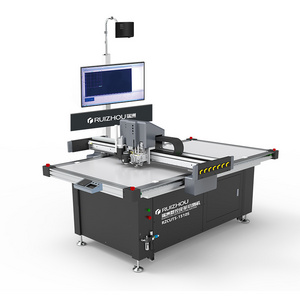

Automatic Digital CNC Genuine Leather Shoes Cutting Machine Tire cow leather CNC Cutter Machine

Model: RZCRT-1510E

C u tting Area: 1500 x 1000mm

Accuracy: 0.1 -1.0mm

Save 5%

ISO CE

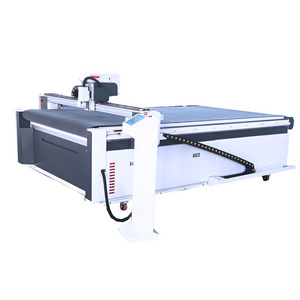

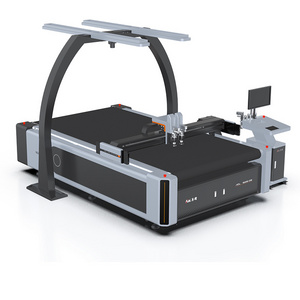

RUIZHOU RZCRT series cutting machines are very useful to cut both soft and hard materials, such as corrugated board,

honeycomb board, chipboard fiber board, cloth, PU, acrylic, EVA, foam etc. RUIZHOU Computerized CNC Cut Machine

can be widely used in footwear, garment, bag&suit case, airplane, package, advertisement, furniture, lamp, box, color

print, packing, car upholstery, apparel, carton and other special applications.

Key Functions:

1.Multi-functional cutting tool, be able to do complete cut, half cut, and dot cut;

2.A group of creasing wheels available for creating folding line on corrugated board with different thickness;

3. Different shapes of cutting blades available for cutting different materials;

4. Powerful vacuum system makes it possible to hold t small piece of material;

5. Accurate positioning through laser registration device;

6. V-cut is available.

1. Servo Motor , which guarantees the good quality, fast speed, stable function.

2. Professional Cutting Head . With one standard cutting head and two more optional cutting heads, the cutting machines meet broad users‘

needs.

3. Oscillatiing Cut Head . faster, more stable. Diffcult patterns, smooth lines.

4. Various cutting tools.

| Model | Cutting Size | Cutting Head & Cutting Arm | Feeding (Rolling) System |

| RZCRT-1410C | 1400mm x 1000mm | 1 & 1 | No |

| RZCRT-1018-2H-2 | 1000mm x 1800mm | 2 & 2 | No |

| RZCRT-1813C | 1800mm x 1300mm | 1 & 1 | No |

| RZCRT-1813-2H | 1800mm x 1300mm |

2 & 1

|

YES |

| RZCRT-1813C-Ⅲ | 1800mm x 1300mm | 2 & 1 | No |

| RZCRT-2516C | 2500mm x 1600mm | 1 & 1 | No |

| RZCRT-2516F | 2500mm x 1600mm | 1 & 1 | YES |

| RZCRT-3016C | 3000mm x 1600mm | 1 & 1 | No |

1.All the models have one standard cutting head. With a group of different knives, hobbing cutter, pinch roller and pen

it can do common cuttings for many different materials, creasing and marking .

2.For all the cutting models one more optional cutting head can also be added according to your need. It will add three

more functions: mill-cuting, v-cutting and punching .

3.Some big or long cutting machines, like RZCRT-2516F and RZCRT-1018-2H-2, can be equiped with an automatic

feeding system or one more cutting arm. This will double the work efficiency.

| Technical Parameter | |||

| Mode | RZCRT-1510E | RZCRT-1813E | RZCRT-2516E |

| Cutting Area | 1500mm x 1000mm | 1800mm x 1300mm | 2500mm x 1600mm |

| Working Character | The cutting machine runs with the computer simultaneously, the data can be transfered fast, and can be used continuously. | ||

| Cutting Speed | 700-1200mm/s | ||

| Cutting Thickness | 0.4mm-55mm, can be adjusted according to the material and customers' requirement. | ||

| Cutting Materials | Corrugated paper, Honeycomb board, Plastic, Rubber board, Greyboard, Leather, PVC, PU, Acrylic, composite materials, etc. | ||

| Knife | Oscillating blade head, Milling Cutter, Hobbing Cutter, Creasing Wheel | ||

| Applicable Pen Type | Common signing pen, Oil pen, ball-point pen, Silver pen | ||

| Mesaure to Fix Material | Divisional vacuum absorption | ||

| Mechanical Resolution | 0.07mm | ||

| Software Resolution | 0.025mm, 0.01mm, 0.1mm (optional) | ||

| Interface of Transmission | Standard parellel and serial interface | ||

| Buffer Capability | Once fast transfer | ||

| Command | HP-GL and GP-GL compatible mode | ||

| Digital Control Panel | Liquid crystal display and touching button | ||

| Transimission Materials | Staight line guide track/ Synchronous belt/ Imported synchronous belt | ||

| Motor | Servo motor | ||

| Cutting Blade Rotate | Vibrational cutting head 18000r/min, milling spindle motor 4000-1000r/min | ||

| Machine Working Voltage | AC 220V ± 10%, 50HZ | ||

| Air Pump working Voltage | AC 380V ± 10%, 50 HZ | ||

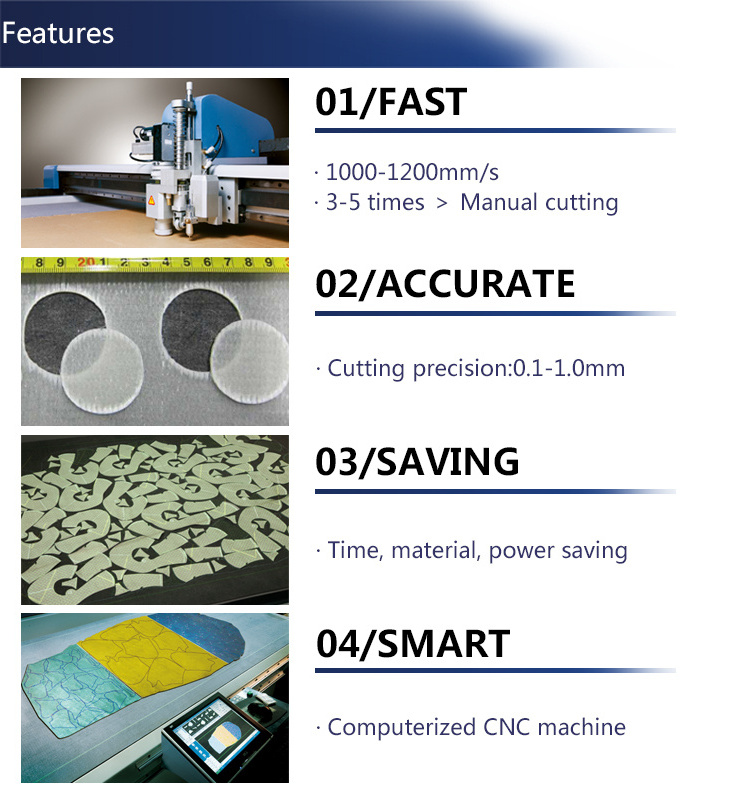

1.Fast

The cutting speed of Ruizhou carton cutting machine is 3 to 5 times the speed of traditional manual cutting, with

maximum cutting speed of 1000mm/s to 1200mm/s. It's more suitable for the customers who are receiving orders

with diverse styles and short lead time.

2. Accurate

All operations of Ruizhou box sample cutter are computerized to simulate the operation process exactly, which rules

out the interference from the factors of the workers' mood, knowledge, tiredness and other personal factors happened

in traditional cutting, thus avoid hidden waste and ensure the quality of product.

3.Saving

Ruizhou carton cutting machine is connectable to many CAD software. Customers can make timely correction to the

patterns during cutting, thus meeting the fast-changing market demands through quick sample making and error

correction. You are supposed to achieve 2-3 days of time advantage over your competitors in terms of correction

of the same kind of samples.

4.Smart

The cutting machine is a computerized CNC cutting machine. All the sharp turnings can be controlled on the machine.

The depth can be adapted to your needs. Nesting is more convenient and flexible. The cutting knives can be changed.

Innovative Features:

1.The new model complies with European Standard, whose major components are imported from Swiss, US,JAPAN etc.

2. Adopting Swiss high speed vibrating cutting tool, available for any depth setting of the blades;

3. Directly control on all sharp turnings on the machine, convenient and easy to operate;

4. Separate setting on creasing pressure towards X and Y direction according to texture of corrugated board;

5. Special safety sensory device meets the European standard;

6. Configured vacuum muffler in order to lower noise to provide a quiet and comfort working environment.

1.Accurate

High requirement of ourselves and persistent striving for excellent, lead to high accuracy. With our laser location device

and other elaborate devices the cutting machine meets the cutting precision: 0.1mm to 1mm.

2.Smooth

The Oscillating Cutting Tool assures our cutting machines cut smoothly. Even very complex lines, irregular lines, can be

cut smoothly. And this cutting effects can hardly be done by laser cutting machine, die cutter or manual workers.

3.Diverse

Material -- It can cut nearly all of soft materials and some hard materials.

The Cutting thickness -- 0.4mm to 55mm, even larger, according to the material and your requirement.

Function -- complete cutting, half cutting, dot cutting, V- cutting; line folding; marking.

4.Delicate

The cutting machine is able to cut complex patterns with high precision and repeating precision.

It can cut nearly all of soft materials and some hard materials.

Cardboard, corrugated board, honeycomb board, chipboard

Shoe insole, EVA,rubber

Cloth, mash, jean, fiber, many layers

Leather, PVC, PU+cloth

Car mats

Composite materials, plastic, acrylic, resin, etc.

It is used in a lot of areas such as footwear, garment, bag&suit case, airplane, package, advertise m ent , furniture,

lamp, box, color print, packing, car upholstery, apparel, carton and other special applications.

RUIZHOU requite her customers with sincerity. She wins the market with good services, build brand with good quality,

strive for excellence with technology. Over the past years, RUIZHOU has received trust and praise from our customers.

Our product sold to European, Korea, India, Mexico, Malaysia, Vietnam, Hong Kong and Taiwan. The clients we have

severed, at home and abroad, up to 5000 famous companies, includes: ST&SAT, BELLE, DAPHNE, NIKE, ADIDAS,

Guangzhou Honda, Guangzhou TOYOTA, Goldlion and so on.

1 . 20 years of experience in CNC cutting technology;

2. The first and biggest CNC cutting machine manufacturer in China;

3. We f ocus on the research and development of CNC knife-cutting technology and related CAD software over the

past 20 years;

4. HAAS and DMG machine tool are used to produce key components;

5. We imported Servo Motor from Panasonic and Straight-line guide rail from Germany;

6. The quality and service are regarded as the life of our corporation;

7. We will never be satisfied until you are satisfied;

8. Our engineering team never stop to improve our machine and upgrade our software;

9. Ruizhou is based in Foshan, aiming at the global market.

During the past 20 years development, RUIZHOU, with her persistent efforts, high tecnology, and good quality products,

has won lots of precious awards. And the company and products meet high quality standards from both China and the

world. Such as: CE, ISO, Utility model patent, Design Patent, Foshan Institute of Supervision & Test on Product Quality, etc.

1.One year guarantee for whole machine except of consumables such as knife blade, mat.

2.24 hours technical support

3.Calling or door-to-door service

4.Use friendly-English software, usual manual and detailed videos.