- Product Details

- {{item.text}}

Quick Details

-

Number of Row:

-

Single row

-

Bore Size:

-

0 - 7 mm

-

Brand Name:

-

VNV

-

Model Number:

-

NK10/12 NK10/16 NK14/16 NK14/20

-

Place of Origin:

-

Hunan, China

-

Product name:

-

Needle Roller Cage Bearing

-

Application:

-

Automotive.tractor.construction Machinery.rolling Mill

-

Model:

-

NK10/12 NK10/16 NK14/16 NK14/20

-

Material:

-

Chrome Steel GCR15

-

Lubrication:

-

Oil Grease

-

Bearing type:

-

Roller Bearing

-

Cage:

-

Steel Cage

-

OEM:

-

Warmly Welcomed

-

Brand:

-

Customer's Brand

Quick Details

-

Applicable Industries:

-

Manufacturing Plant, Construction works , Energy & Mining

-

Precision Rating:

-

P6

-

Seals Type:

-

OPEN

-

Number of Row:

-

Single row

-

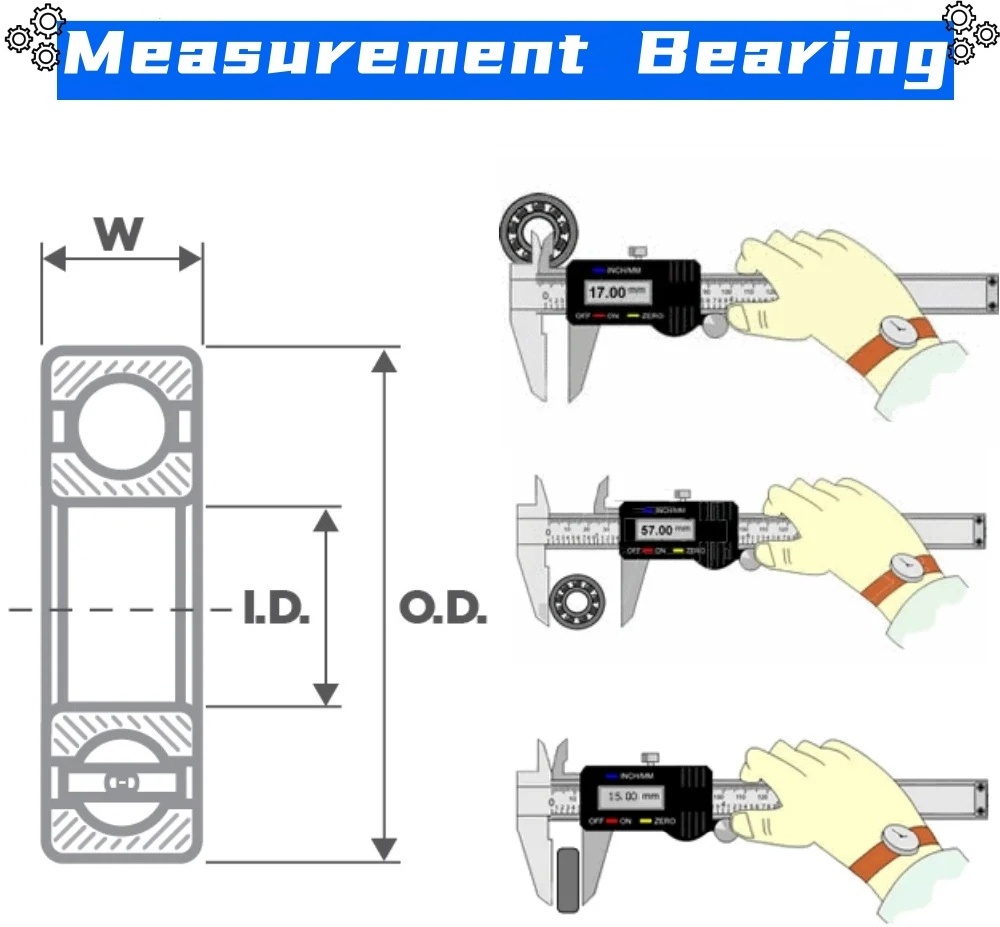

Bore Size:

-

0 - 7 mm

-

Brand Name:

-

VNV

-

Model Number:

-

NK10/12 NK10/16 NK14/16 NK14/20

-

Place of Origin:

-

Hunan, China

-

Product name:

-

Needle Roller Cage Bearing

-

Application:

-

Automotive.tractor.construction Machinery.rolling Mill

-

Model:

-

NK10/12 NK10/16 NK14/16 NK14/20

-

Material:

-

Chrome Steel GCR15

-

Lubrication:

-

Oil Grease

-

Bearing type:

-

Roller Bearing

-

Cage:

-

Steel Cage

-

OEM:

-

Warmly Welcomed

-

Brand:

-

Customer's Brand

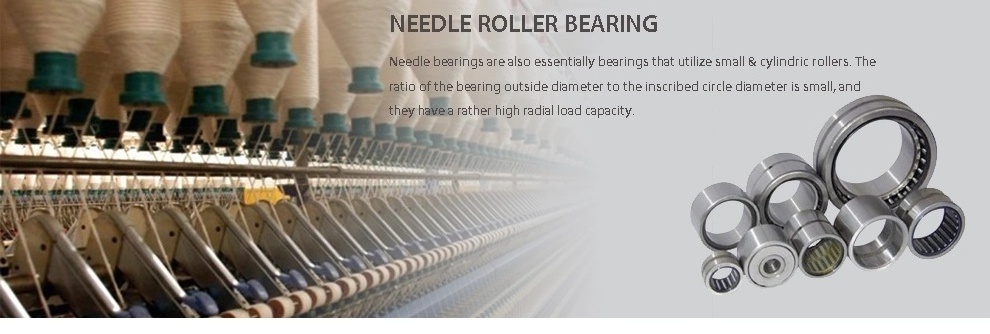

Revolutionize Your Machinery with Needle Roller Bearings: Unleashing Peak Performance and Reliability

High Load Capacity:

Needle bearings are designed with needle-shaped rollers to withstand higher radial and impact

loads, suitable for heavy-duty applications.

High Rigidity: The structural design of bearing needles provides higher axial rigidity, helping maintain stability in

high-speed rotation and vibration environments.

Compact Size and Lightweight: Due to the needle design, split cage needle roller bearing offer smaller dimensions and lighter weight compared to other bearing types, facilitating compact design and weight control in mechanical systems.

High-Speed Performance: The roller structure of micro needle bearing results in low friction and heat generation, making

them suitable for high-speed rotation applications, improving the efficiency of mechanical systems.

High Precision: roller needle bearing typically adhere to high precision manufacturing standards, suitable for applications requiring accurate position control, such as machine tools and precision instruments.

High-Temperature Resistance: Some manufactures needle roller bearing are designed for high-temperature environments, using special materials and lubricants to ensure stability and performance under elevated temperatures.

loads, suitable for heavy-duty applications.

High Rigidity: The structural design of bearing needles provides higher axial rigidity, helping maintain stability in

high-speed rotation and vibration environments.

Compact Size and Lightweight: Due to the needle design, split cage needle roller bearing offer smaller dimensions and lighter weight compared to other bearing types, facilitating compact design and weight control in mechanical systems.

High-Speed Performance: The roller structure of micro needle bearing results in low friction and heat generation, making

them suitable for high-speed rotation applications, improving the efficiency of mechanical systems.

High Precision: roller needle bearing typically adhere to high precision manufacturing standards, suitable for applications requiring accurate position control, such as machine tools and precision instruments.

High-Temperature Resistance: Some manufactures needle roller bearing are designed for high-temperature environments, using special materials and lubricants to ensure stability and performance under elevated temperatures.

Variety of Sizes and Models:

Excavator needle bearing

offer a range of sizes and models to meet the requirements of different applications, including various diameters, lengths, and load capacities.

Long Life and Reliability:

Radial needle roller bearings

use high-quality materials and advanced manufacturing processes to provide long life and reliability, reducing maintenance costs.

Easy Installation and Maintenance: C ombined needle roller bearings are designed for easy installation and maintenance, minimizing downtime and maintenance costs.

Adaptability to Various Environments: S mall needle roller bearing can adapt to different working environments, including high and low temperatures, high-speed, heavy loads, etc., making them versatile for a variety of applications.

Easy Installation and Maintenance: C ombined needle roller bearings are designed for easy installation and maintenance, minimizing downtime and maintenance costs.

Adaptability to Various Environments: S mall needle roller bearing can adapt to different working environments, including high and low temperatures, high-speed, heavy loads, etc., making them versatile for a variety of applications.

|

item

|

Needle Roller Cage Bearing

|

|

Bore Size

|

0mm - 7mm

|

|

Applicable Industries

|

Manufacturing Plant, Construction works , Energy & Mining

|

|

Type

|

Needle

|

|

Brand Name

|

VNV

|

|

Model Number

|

NK10/12 NK10/16 NK14/16 NK14/20

|

|

Precision Rating

|

P6

|

|

Seals Type

|

OPEN

|

|

Number of Row

|

Single row

|

|

Place of Origin

|

China

|

|

Product name

|

Needle Roller Cage Bearing

|

|

Application

|

Automotive.tractor.construction Machinery.rolling Mill

|

|

Model

|

NK10/12 NK10/16 NK14/16 NK14/20

|

|

Type

|

Single Row Needle Roller Bearing

|

|

Material

|

Chrome Steel GCR15

|

|

Lubrication

|

Oil Grease

|

|

Bearing type

|

Roller Bearing

|

|

Cage

|

Steel Cage

|

|

OEM

|

Warmly Welcomed

|

|

Brand

|

Customer's Brand

|

Hot Searches