The special CNC system of intelligent laser cutting machine is adopted to realize automatic edge searching, automatic typesetting,

automatic focusing, automatic cutting, convenience and efficiency.

- Product Details

- {{item.text}}

Quick Details

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

220*6000mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HUAXIA

-

Weight (KG):

-

3000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Cutting materials:

-

Metal Materails

-

Laser head:

-

Raytools Cutting Head

-

Laser source:

-

IPG Raycus MAX JPT

-

Control system:

-

Cypcut System

-

Working area:

-

Custmize

-

Color:

-

Customer Requirement

-

Motor:

-

Japan Yaskawa Motor

Quick Details

-

Laser Type:

-

Fiber Laser

-

Cutting Speed:

-

140m/min

-

Cooling Mode:

-

WATER COOLING

-

Control System Brand:

-

Cypcut

-

Cutting Area:

-

220*6000mm

-

Cutting Thickness:

-

0-30mm

-

Control Software:

-

Cypcut

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HUAXIA

-

Weight (KG):

-

3000 KG

-

Product name:

-

Fiber Laser Metal Cutting Machine

-

Keyword:

-

Fiber Laser Cutting Machiens

-

Laser power:

-

1000W / 2000W / 3000W/4000W

-

Cutting materials:

-

Metal Materails

-

Laser head:

-

Raytools Cutting Head

-

Laser source:

-

IPG Raycus MAX JPT

-

Control system:

-

Cypcut System

-

Working area:

-

Custmize

-

Color:

-

Customer Requirement

-

Motor:

-

Japan Yaskawa Motor

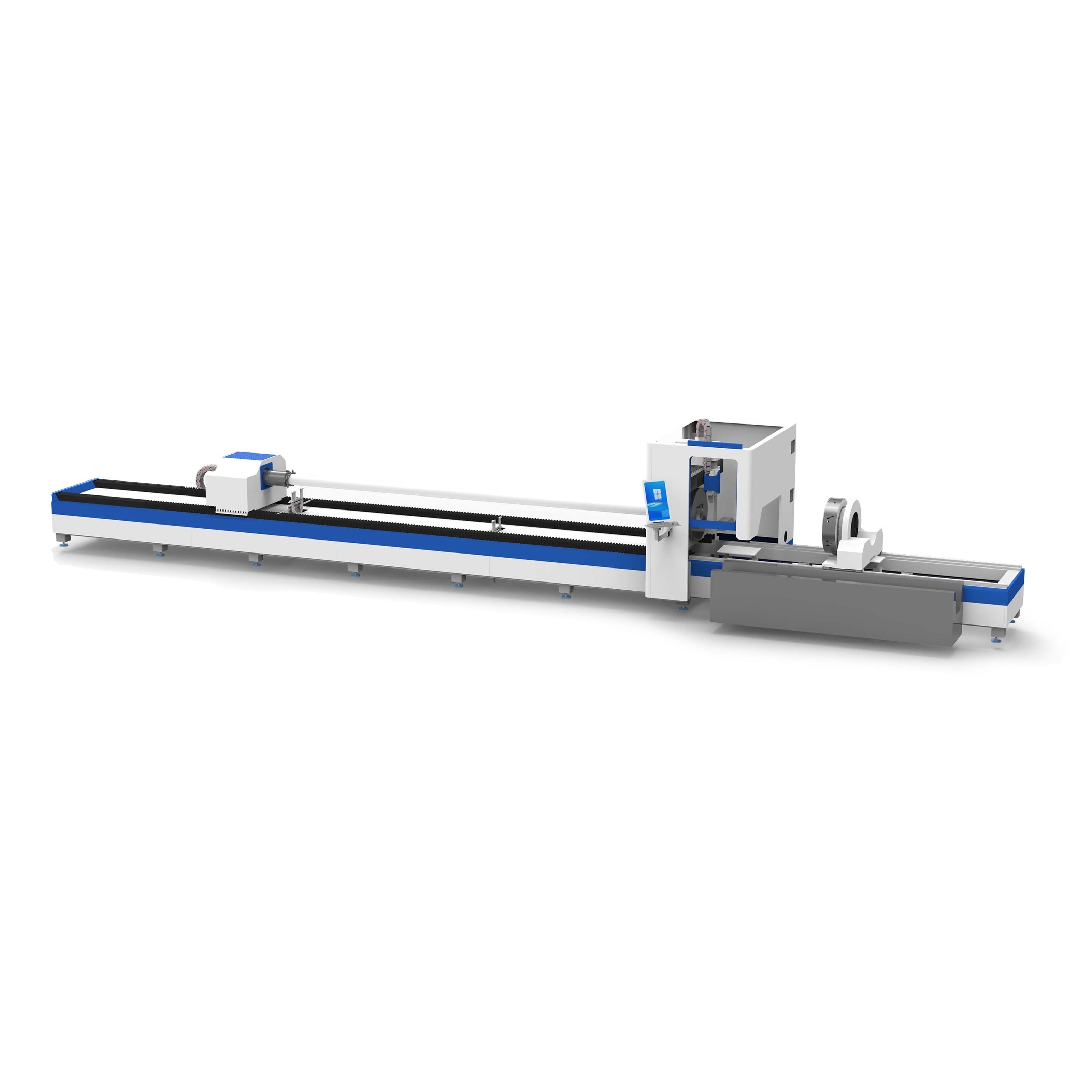

PIPE LASER CUTTING MACHINE

Details and advantages

Main parameter

|

Model

|

HXF-6000

|

HXF-6000

|

HXF-6000

|

HXF-6000

|

HXF-6000

|

HXF-6000

|

|||||

|

Processing length(mm)

|

6000

|

6000

|

6000

|

6000

|

6000

|

6000

|

|||||

|

Machining diameter(mm)

|

350

|

350

|

350

|

350

|

350

|

350

|

|||||

|

Cutting power

|

1000W-12000W

|

|

|

|

|

|

|||||

|

Cutting speed

|

100m/min

|

|

|

|

|

|

|||||

|

positioning accuracy

|

0.02mm

|

|

|

|

|

|

|||||

Product introduction

Stable performance

High efficiency

Your first choice

This machine is widely used in the cutting and processing of pipeline structures in the industries of construction, chemical industry, shipbuilding, mechanical engineering, metallurgy, electric power, etc.

The machine can cut metal and other materials seamlessly. After programming, the machine can be widely used for customized cutting operations.

It can perform complex cutting faster. For example, drilling and cutting various shapes on pipes of various shapes and sizes. In addition, the laser cutting tube can provide a good cutting cross-section, and the subsequent welding does not require secondary treatment, which is also applicable to the cutting of thin-walled tubes and thick walled tubes. The real difference of laser pipe cutting is the cutting accuracy. Due to the improvement of China's modern research laser cutting machine, the application of industrial production and manufacturing technology involving small diameter pipes has been greatly accelerated.

The computer aided design software is used for graphic design of laser cutting, and the cutting machine operating system is imported for automatic cutting, so as to greatly improve the speed of manufacturing projects with Z. Typically, the operating system includes a database with key information such as the material type, thickness, and geometry of the tube.

Product Configuration

High precision bed

High quality square tube welding and three pass welding process are adopted, which are sturdy and durable.

The structural materials are annealed at high temperature to eliminate internal stress, so that the machine bed can maintain good mechanical properties such as tensile strength, toughness, hardness and deformation resistance.

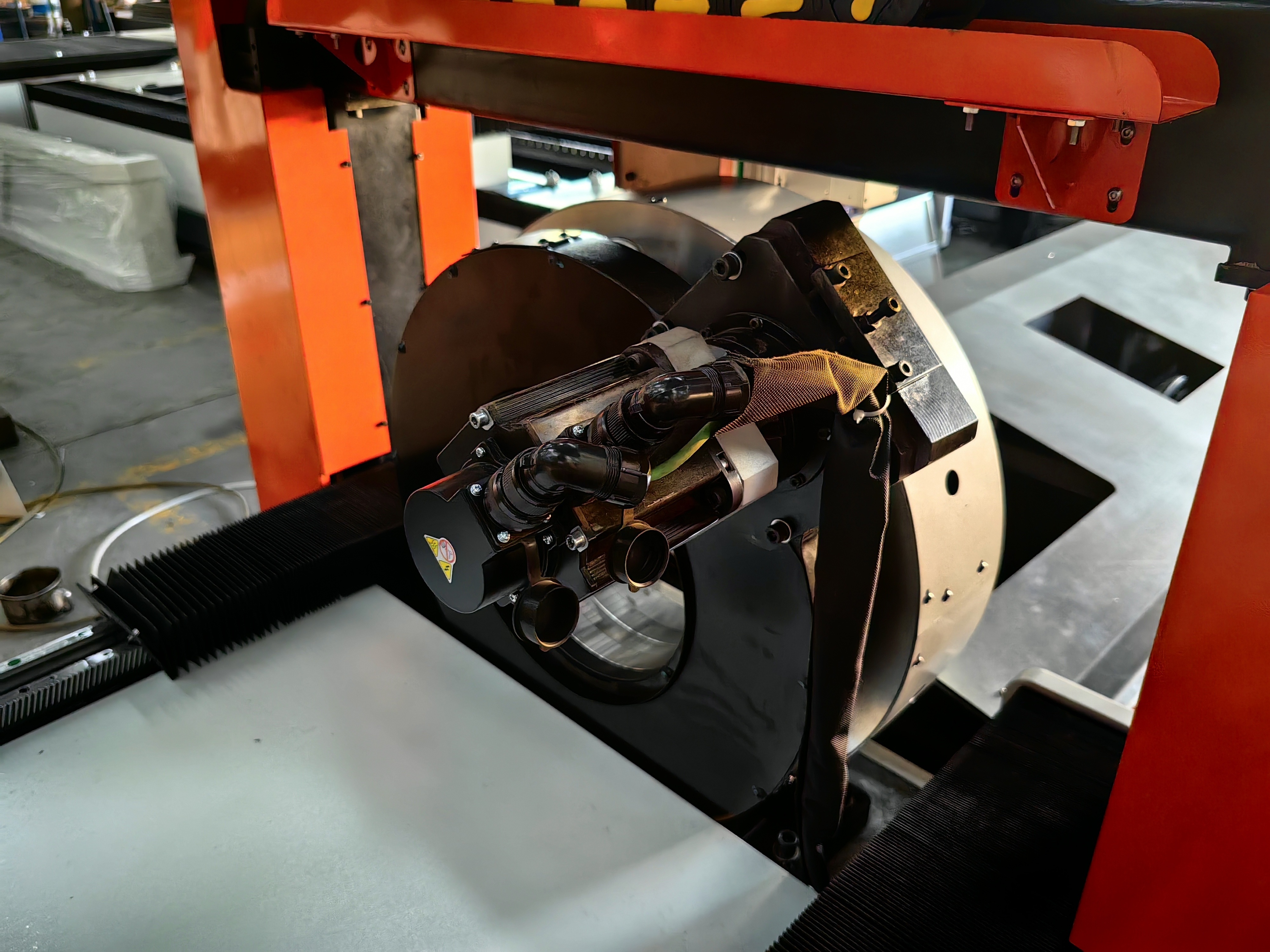

High precision beam

Double pneumatic chucks, one key clamping and automatic centering are adopted to reduce the waiting time for loading and unloading, with high accuracy and speed, and ensure the cutting accuracy.

Material suitable for cutting

Flexible and diverse, powerful performance, can cut round pipe, square pipe, oval pipe, U-shaped steel, L-shaped steel, H-shaped steel.

CNC system

Driver system

High precision servo motor, high-precision reducer, high-precision guide rail and rack are

used to ensure the high speed and acceleration of the whole machine.

Special laser head

Professional laser cutting head, stable and reliable technology, completely sealed inside

the laser head, can avoid dust pollution to the optical part. The protective lens is installed in a drawer, which is convenient

for replacement.

Laser generator

Laser generators are famous brands. Provide high performance, high quality,cost-effective laser generator integration solutions

and professional and perfect service experience in the global laser field.

and professional and perfect service experience in the global laser field.

Cutting sample

Applicable to the industry

Hot Searches