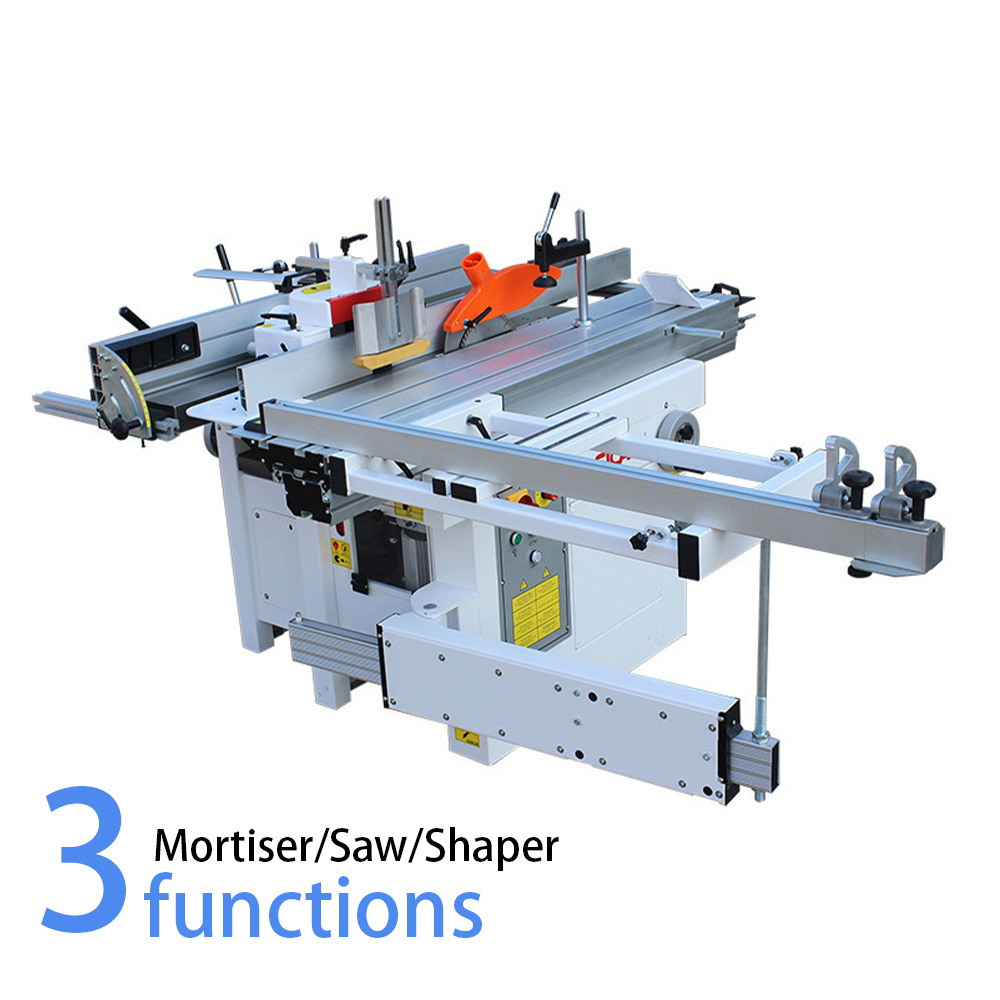

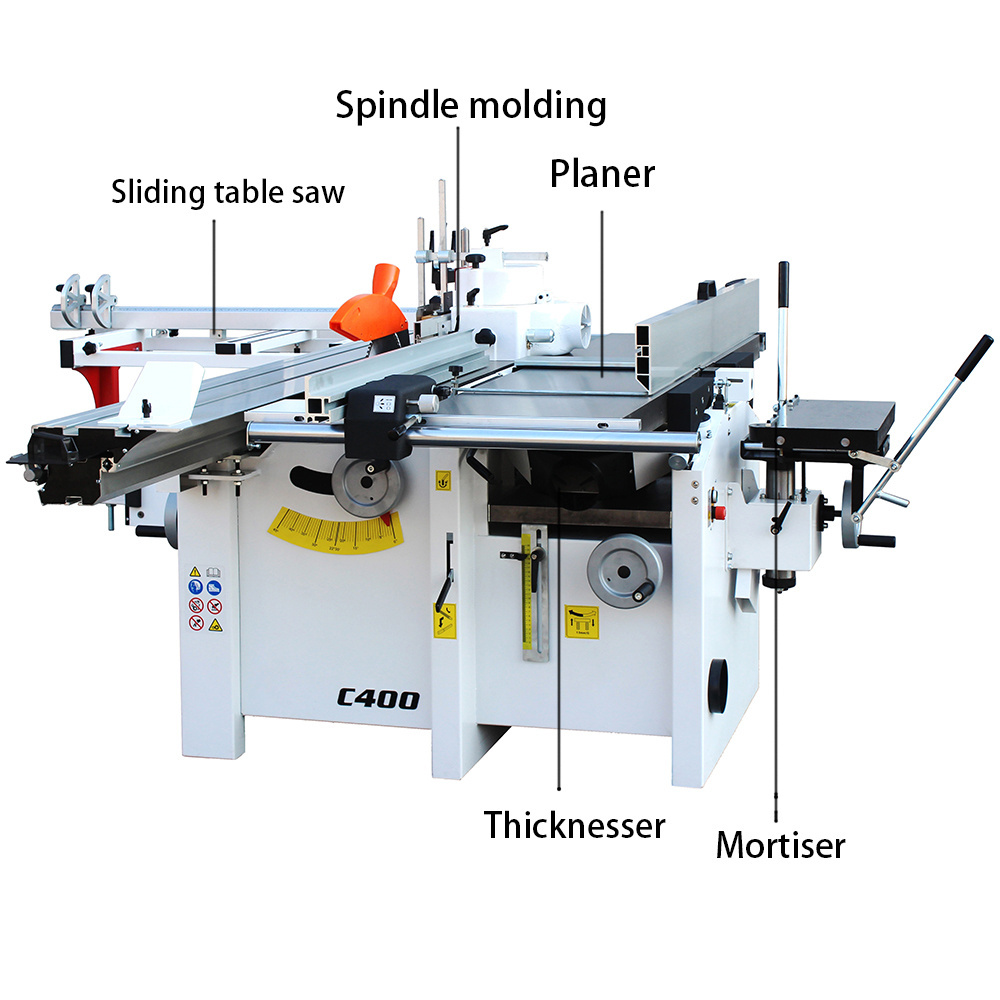

The C400 Combined Machine has been specifically designed be an industrial standard machine, but at a size intended for the factory and small professional workshop. This industrially rated machine features a table saw and sliding table, planer, thicknesser and spindle moulder unit. The cast iron construction, accurate cross cut fence and superb build quality put this machine in a class of its own.

Being a professional standard machine, the C400 of course is fully adjustable and the accuracy is second to none. As far as accuracy goes it will not even be bettered by full sized industrial machines. With three independent class 1 motors providing ample power, changing function can be done with the flick of a switch rather than the going through the laborious task of changing belts.

The saw utilises a sliding beam which runs along side the blade like a panel saw. By running the beam this close to the blade, 100% accuracy is assured.

The planer thicknessing function, again is of the highest quality, extremely powerful, accurate and the end result is simply sublime. The inward swing of the thicknessing unit keeps this machine compact in every function,whilst the cast iron construction means even heavy pieces can be handled confidently.

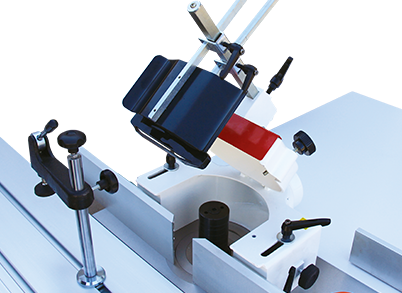

Several further options are also available, each machine can therefore be tailored to the users specific needs. These options include; heavy duty morticing unit, spindle moulder ring fence, power feeder and tenoning hood.

- Product Details

- {{item.text}}

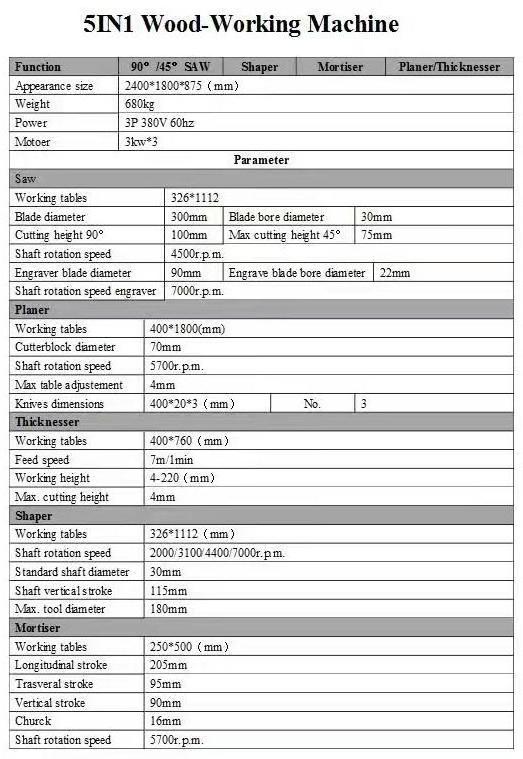

Quick Details

-

Dimension(L*W*H):

-

2400*1800*875mm

-

Application:

-

Multifunction, Furniture Industry

-

Weight (KG):

-

680 KG

-

Power (kW):

-

9KW

-

Max.Cutting Height at 90°(mm):

-

100mm

-

Max.Cutting Height at 45°(mm):

-

75mm

-

Max. Length of Workpiece (mm):

-

800mm

-

Product name:

-

C400 Combined Machine

-

Keyword:

-

Multifunctional Wood Planer

-

Function:

-

Cutting, flat planing, thickness, spindle forming, mortise and tenon

-

Cutting material:

-

Wood

-

After Warranty Service:

-

Video Technical Support Online Support

Quick Details

-

Place of Origin:

-

Chine

-

Brand Name:

-

OEM

-

Voltage:

-

380V / Custom

-

Dimension(L*W*H):

-

2400*1800*875mm

-

Application:

-

Multifunction, Furniture Industry

-

Weight (KG):

-

680 KG

-

Power (kW):

-

9KW

-

Max.Cutting Height at 90°(mm):

-

100mm

-

Max.Cutting Height at 45°(mm):

-

75mm

-

Max. Length of Workpiece (mm):

-

800mm

-

Product name:

-

C400 Combined Machine

-

Keyword:

-

Multifunctional Wood Planer

-

Function:

-

Cutting, flat planing, thickness, spindle forming, mortise and tenon

-

Cutting material:

-

Wood

-

After Warranty Service:

-

Video Technical Support Online Support

5 in 1 3in1 horizontal wood woodworking combinate multifunction table saw machine with planer

Thicknesser

Sheper

Saw

Planer

Mortiser

Internal structure

Our production process:

1,The machine body is stronger with 6mm thick steel. All the components saw body are cut by laser cutting machine, smoother without burr.

2, Our own cast iron table is 136kgs, the largest one in Qingdao. It is thicker and with more reinforcing ribs. The surface is

grinded and polished by CNC lathing-milling center. There will be no deformation after fixing the motors on it. Electrostatic

powder spraying to improve corrosion resistance and wear-resistance. Processing by gantry milling machine, the double layers sliding table is more stable and durable.

3, Inner parts are processed by CNC machining center, to guarantee high precision.

4, Pulleys are corrected by computer by dynamic balancing machine, to keep the pulleys’ accuracy within 1 gram. Running smoothly without bounce.

5, All the purchased parts are famous brands, for example, SKF bearings from German.

6, Flatness detection of sliding table. Linearity testing on both saw blades.

7,Ruler accuracy detection. To get the accurate cutting dimension .

8, Angle detection to keep high angle precision during cutting in different angles. Saw blades bounce detection to keep high cutting precision. Electrical safety testing. Noise measuring. To keep below 85 decibels. (The max. Allowed noise is 115 decibels).

9,Package and transferring to warehouse after all the items confirm to the standards.

1,The machine body is stronger with 6mm thick steel. All the components saw body are cut by laser cutting machine, smoother without burr.

2, Our own cast iron table is 136kgs, the largest one in Qingdao. It is thicker and with more reinforcing ribs. The surface is

grinded and polished by CNC lathing-milling center. There will be no deformation after fixing the motors on it. Electrostatic

powder spraying to improve corrosion resistance and wear-resistance. Processing by gantry milling machine, the double layers sliding table is more stable and durable.

3, Inner parts are processed by CNC machining center, to guarantee high precision.

4, Pulleys are corrected by computer by dynamic balancing machine, to keep the pulleys’ accuracy within 1 gram. Running smoothly without bounce.

5, All the purchased parts are famous brands, for example, SKF bearings from German.

6, Flatness detection of sliding table. Linearity testing on both saw blades.

7,Ruler accuracy detection. To get the accurate cutting dimension .

8, Angle detection to keep high angle precision during cutting in different angles. Saw blades bounce detection to keep high cutting precision. Electrical safety testing. Noise measuring. To keep below 85 decibels. (The max. Allowed noise is 115 decibels).

9,Package and transferring to warehouse after all the items confirm to the standards.

Qingdao XINREBON CNC Technology CO., LTD

XINREBON CNC TECHNOLOGY CO., LTD, we are a professional manufacturing company. The factory is located in Shandong province, 20 km from Qingdao port and only 10 km from the high speed railway station. Based on efficient transportation, our machines can reach consumers directly and easily. We always walk on the road of technological innovation and our products are constantly upgraded. Currently, our machines serve consumers in more than 20 provinces in China and more than 30 countries abroad, enjoying high reputation and acclaim. Combined with years of experience, we have won the trust and praise of our customers. Now we produce all kinds of woodworking machines, including edge banding machines, cold/hot presses, planers, sanding machines, polishing machines, CNC routers, CNC panel cutting saws, horizontal band saws, multi-row drilling machines, precision push table sawing machines, various solid wood processing machines, etc. Our philosophy: professional, efficient and loyal, our mission: to create core value for our customers, our employees and our company..

Q1: Can you provide OEM or ODM services?

A: Of course, we have our own design department, and we can provide OEM or ODM services for you.

Q2: What is your minimum order quantity?

A: Hello, the minimum order quantity we support is one.

Q3: How long is the warranty period of your machine and what kind of warranty service can I get?

A: Our machines are provided with a one-year after-sales warranty and lifelong service. If there is any problem with the machine, please contact us. We guarantee to solve the problem for you within 24-48 hours, and if the machine parts are damaged for non-human reasons during the warranty period, we can send you free parts, except for consumables.

Q4: If I pay for the goods, when will you deliver the goods?

A: Hello, the normal machines are in stock. We will deliver the goods to the shipping company within 5-7 days to achieve fast shipment, but the shipping time depends on the shipping company.

A: Of course, we have our own design department, and we can provide OEM or ODM services for you.

Q2: What is your minimum order quantity?

A: Hello, the minimum order quantity we support is one.

Q3: How long is the warranty period of your machine and what kind of warranty service can I get?

A: Our machines are provided with a one-year after-sales warranty and lifelong service. If there is any problem with the machine, please contact us. We guarantee to solve the problem for you within 24-48 hours, and if the machine parts are damaged for non-human reasons during the warranty period, we can send you free parts, except for consumables.

Q4: If I pay for the goods, when will you deliver the goods?

A: Hello, the normal machines are in stock. We will deliver the goods to the shipping company within 5-7 days to achieve fast shipment, but the shipping time depends on the shipping company.

Hot Searches