- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

DY-MN-Sn-012

-

Shape:

-

nano powder, Spherical nano particle

-

Material:

-

Tin powder

-

Chemical Composition:

-

Tin

-

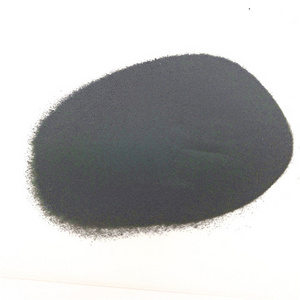

Appearance:

-

Black powder

-

Certificate:

-

ISO9001:2000

-

CAS:

-

7440-31-5

-

EINECS:

-

231-141-8

Quick Details

-

Application:

-

lubricating additives

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

DYNANO

-

Model Number:

-

DY-MN-Sn-012

-

Shape:

-

nano powder, Spherical nano particle

-

Material:

-

Tin powder

-

Chemical Composition:

-

Tin

-

Appearance:

-

Black powder

-

Certificate:

-

ISO9001:2000

-

CAS:

-

7440-31-5

-

EINECS:

-

231-141-8

50nm Nano Tin powder ( Tin Sn metal Ultrafine powder)99.99%

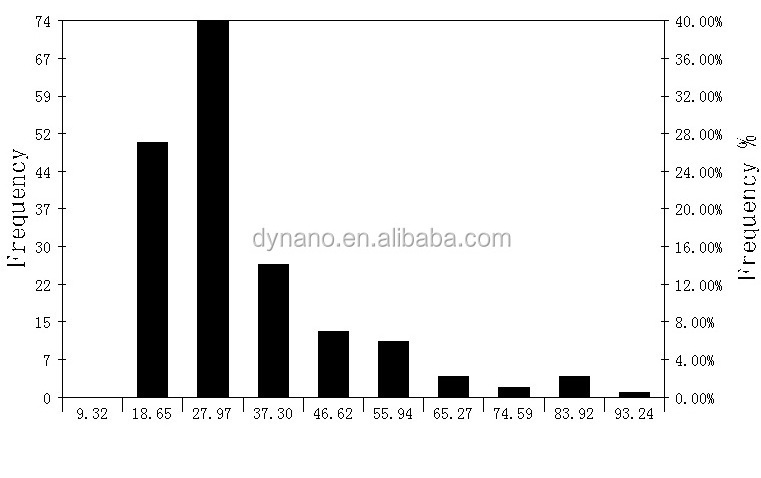

Technical Parameters

|

Model |

APS(nm) |

Purity(%) |

Specific surface area(m 2 /g) |

Volume density(g/cm 3 ) |

Crystal form |

Color |

|

|

Nano |

DY-Sn-005 |

50 |

>99.9 |

45.3 |

0.42 |

spherical |

black |

|

Micron |

DY-Sn-002 |

800 |

99.8 |

9.23 |

1.63 |

spherical |

Black grey |

|

Note: |

according to user requirements of nano particle can provide different size products. |

||||||

Product performance

Nano tin powder by variable current laser ion beam, chemical vapor deposition of industrialization production is big, high purity, uniform particle size, shape, good dispersibility, high oxidation temperature and good sintering shrinkage.

Application direction

- Metal nanometer lubricating additives: add 0.1 ~ 0.5% nano tin powder to lubricating oil, grease, make the friction pair in the process of friction surface self-lubricating, self-healing membrane, significantly reduce the friction pair antiwear and antifriction performance.

- Activated sintering additives: nano tin powder in the powder metallurgy slash powder metallurgy sintering temperature and high temperature ceramic products.

- Metal and non-metallic conductive coating on the surface treatment: under anaerobic conditions, below the powder coating of the melting point temperature, the technology can be used in the production of microelectronic device.

Storage conditions

This product should be stored in dry, cool and sealing of the environment, can not be exposure to air, in addition should avoid the heavy pressure, according to ordinary goods transportation.