Here we introduce the double planetary mixer-mixing lithium battery slurry or 100000cps slurry

- Product Details

- {{item.text}}

Quick Details

-

Max. Loading Capacity:

-

100L

-

Weight (KG):

-

2700 KG

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Yushun

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2300x1300x2400mm

-

Power (kW):

-

15 kW

-

Machine Type:

-

Planetary mixer

-

Tank Size:

-

650x450mm

-

Motor:

-

Double - Revolution Motor and Disperse Motor

-

Application scope:

-

Chemicals Processing

-

Function:

-

Mixer Blender

-

Capacity:

-

100L

-

Weight:

-

2700KG

-

Keywords:

-

mixer

Quick Details

-

Barrel Volume (L):

-

149

-

Max. Loading Volume (L):

-

100 L

-

Range of Spindle Speed(r.p.m):

-

1 - 30 r.p.m

-

Max. Loading Capacity:

-

100L

-

Weight (KG):

-

2700 KG

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Yushun

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

2300x1300x2400mm

-

Power (kW):

-

15 kW

-

Machine Type:

-

Planetary mixer

-

Tank Size:

-

650x450mm

-

Motor:

-

Double - Revolution Motor and Disperse Motor

-

Application scope:

-

Chemicals Processing

-

Function:

-

Mixer Blender

-

Capacity:

-

100L

-

Weight:

-

2700KG

-

Keywords:

-

mixer

Automatic Vacuum Double Planetary Mixing Machine High Speed Powerful Mixer For Pouch Cell Electrode Making

There Are Many Types Mixing Equipment, how To Choose The Suitable Mixer?

We need to know the material characters as below:

1. Material

2. Viscosity and solid content

3. temperature request(heating or cooling)

4. Vacuum or not

5. Explosion-proof or not

6. Capacity or output request

7. other related equipment needs

8. other special request

Based on above details, we could advice you the suitable mixer from below several normal mixing equipment

A

ll details must be confirmed in advance, because in this way our engineers can make the most perfect technical parameters and quotation.

Different mixers have different applicable materials and scenarios.

Our technical engineers will usually give a rough judgment based on previous experience, referring to the type of material, viscosity and solid content.

Product Description

Title goes here.

During the running of double planetary Vacuum power mixer, Two parallel mixing paddles run in accord with the set fixed rotation ratio, high speed rotating on its own axis at the same time of orbital revolution. There is scraper runs together with

paddles' orbital revolution in the mixing tank, which moves the material to the paddles from tank wall. To archive the different shearing. The direction of both orbital revolution and rotating on its own axis can before ward and reversal: Another two high speed dispersing discs with separate driving device run in the mixing tank together with the orbital revolution, high speed dispersing, emulsification, The speed of high speed dispersing discis adjusted by frequency inverter, The speed can be set in accord with demand.

The material can be completely well distributed emulsifving under this mixing mode,suitable for the dispersing andmixing of solid-solid. solid-liquid and liquid-liquid material.

paddles' orbital revolution in the mixing tank, which moves the material to the paddles from tank wall. To archive the different shearing. The direction of both orbital revolution and rotating on its own axis can before ward and reversal: Another two high speed dispersing discs with separate driving device run in the mixing tank together with the orbital revolution, high speed dispersing, emulsification, The speed of high speed dispersing discis adjusted by frequency inverter, The speed can be set in accord with demand.

The material can be completely well distributed emulsifving under this mixing mode,suitable for the dispersing andmixing of solid-solid. solid-liquid and liquid-liquid material.

Product Paramenters

|

Items

Model

|

30L

|

60L

|

100L

|

200L

|

|||

|

Tank working Capacity/L

|

30L

|

60L

|

100L

|

200L

|

|||

|

Tank Design Size/L

|

44L

|

88L

|

149L

|

287L

|

|||

|

Tank Size/mm

|

400*350

|

500*450

|

650*450

|

750*650

|

|||

|

Revolution Motor/Kw

|

3

|

7.5

|

11

|

22

|

|||

|

Revolution Speed/rpm

|

0-43

|

0-36

|

0-30

|

0-28

|

|||

|

Mix Speed/rpm

|

0-84

|

0-53

|

0-46

|

0-39

|

|||

|

Disperse Motom/Kw

|

5.5

|

11

|

15

|

30

|

|||

|

Disperse Speed/rpm

|

0-5500

|

0-4500

|

0-3700

|

0-2800

|

|||

|

Disperse plate linear Velocity(m/s)

|

0-23

|

|

|

|

|||

|

Suttle/Kg

|

980

|

1700

|

2700

|

4200

|

|||

|

Measurement/mm (L*W*H)

|

1700*950*1900

|

1950*1200*2150

|

2300*1300*2400

|

2500*1400*3000

|

|||

Product Features

Main Features

1.High line speed: The line speed can reach to 25m/s, shorten the dispersing time. The particle size of battery slurry is small and high uniformity, solve the problem of polymerization;

2.It adopts SKF Sweden import angular contact ball bearing.the vertical and horizontal loading is bigger than the deep groove ball bearing. the carry capacity ismuch higher,and bear higher rotating speed, large increase the mixing speed and using life( The using life is more than 3 years under 21m/s and continuous 24hrworking);

3.0-0 assembling: precision assemble, the process tolerance of core parts is less than 30um (mixing shafts, dispersing shafts, and each hole).thus ensure theconcentricity and flatness, archive the 0-0 assembling of core parts. The running is more stable , the noisy outside I m rang is lower than 70 db(A);

4.High tightness, no air leakiness and oil leakiness: 2 sets of mechanical seal plus soft.hard seals ete.the planetary

transmission box adopts complete sealstructure, New design of bearing position, reasonable distribution of the bearing limit, reduce the wearing of bearing. the non load vacuum keeps above -0.092in 24hours, ensure that no air leakiness and oil leakiness during the mixing

5.The gap between tank and paddles: paddles to paddles,paddles to tank wall,paddles to tank bottom, the gap is small, scraper design under the mixing paddles,high roundness inner the tank. The deviation is less than 0.2mm;

6.Large torsion output: precision casting mixing paddles SS316 stainless steel (adopts special steel for machines bigger than 650L, the material can restore itselfif there is micro deformation, the mixing paddles won't deform under long time big torque running), the torque output is simulation calculated by computer.High strength, suitable for high viscosity, high solid content Positive and negative pole slurry of Lithium battery (Lithium iron phosphate, ternary, ternary highnickel, Potassium manganate, Lithium Cobaltate etc) suitable for different process technolog.

2.It adopts SKF Sweden import angular contact ball bearing.the vertical and horizontal loading is bigger than the deep groove ball bearing. the carry capacity ismuch higher,and bear higher rotating speed, large increase the mixing speed and using life( The using life is more than 3 years under 21m/s and continuous 24hrworking);

3.0-0 assembling: precision assemble, the process tolerance of core parts is less than 30um (mixing shafts, dispersing shafts, and each hole).thus ensure theconcentricity and flatness, archive the 0-0 assembling of core parts. The running is more stable , the noisy outside I m rang is lower than 70 db(A);

4.High tightness, no air leakiness and oil leakiness: 2 sets of mechanical seal plus soft.hard seals ete.the planetary

transmission box adopts complete sealstructure, New design of bearing position, reasonable distribution of the bearing limit, reduce the wearing of bearing. the non load vacuum keeps above -0.092in 24hours, ensure that no air leakiness and oil leakiness during the mixing

5.The gap between tank and paddles: paddles to paddles,paddles to tank wall,paddles to tank bottom, the gap is small, scraper design under the mixing paddles,high roundness inner the tank. The deviation is less than 0.2mm;

6.Large torsion output: precision casting mixing paddles SS316 stainless steel (adopts special steel for machines bigger than 650L, the material can restore itselfif there is micro deformation, the mixing paddles won't deform under long time big torque running), the torque output is simulation calculated by computer.High strength, suitable for high viscosity, high solid content Positive and negative pole slurry of Lithium battery (Lithium iron phosphate, ternary, ternary highnickel, Potassium manganate, Lithium Cobaltate etc) suitable for different process technolog.

Application

1. Engineering adhesives: RTV silicon rubbersilicon rubber for construction( silicone sealant,Acid glass adhesive),silicon rubber for mechanics,electronic polyurethane-double component polyurethane sealant, single component polyurethane sealant, glass sealant, organic sealant;

2. Coatings: Decorative coatings、Anu-corrosion coatings, electric conduction coatings, Anti-rust coatings, high temperature resistance coatings, temperature-sensitive coatings, heat-insulating coatings, titanium pigment;

3. Ink:Silicone plastic button ink, modified plastic ink,metallic glass inks, shoe material ink, ABS ink, PU ink, UV ink,ink

additives, pigment ink, special ink for silica gel;

4. New Energy: Fuel cells, power battery, polymer lithium ion battery (LIP), button battery, lithium iron phosphate battery,

battery for electrombile, lithium powerbattery,nickel metal hydride battery,mercury-free alkalinc zinc-manganese

battery,lithium(lithium ion) plastic battery, electrochemical energy storage supercapacitors、lithium ion battery slurry;

5. Electronic( electric slurry paste): Solder paste, lead-solder paste, lead-free solder paste, solder paste, dielectric paste,

resistance paste, conductor paste, solderflux, cleaning agent, soft magnetic material, hydromagnetic material, clectronic

electrode paste, ceramic paste, magnetic material, electronic coating, electronicadhesives, electronic and electrical parts

grouting glue, hot melt glue;

6. Biopolymer gels, medical couplers, ointments, toothpaste, dental products;

7. Food: Chocolate, gum, maltose, jam, pcanut butter, condiment

8. Others: Fine Chemicals, new chemicals, polymer materials, Kaolin, low, medium and high viscosity materials (Liquid-Liquid, Liquid-Solid)..…

2. Coatings: Decorative coatings、Anu-corrosion coatings, electric conduction coatings, Anti-rust coatings, high temperature resistance coatings, temperature-sensitive coatings, heat-insulating coatings, titanium pigment;

3. Ink:Silicone plastic button ink, modified plastic ink,metallic glass inks, shoe material ink, ABS ink, PU ink, UV ink,ink

additives, pigment ink, special ink for silica gel;

4. New Energy: Fuel cells, power battery, polymer lithium ion battery (LIP), button battery, lithium iron phosphate battery,

battery for electrombile, lithium powerbattery,nickel metal hydride battery,mercury-free alkalinc zinc-manganese

battery,lithium(lithium ion) plastic battery, electrochemical energy storage supercapacitors、lithium ion battery slurry;

5. Electronic( electric slurry paste): Solder paste, lead-solder paste, lead-free solder paste, solder paste, dielectric paste,

resistance paste, conductor paste, solderflux, cleaning agent, soft magnetic material, hydromagnetic material, clectronic

electrode paste, ceramic paste, magnetic material, electronic coating, electronicadhesives, electronic and electrical parts

grouting glue, hot melt glue;

6. Biopolymer gels, medical couplers, ointments, toothpaste, dental products;

7. Food: Chocolate, gum, maltose, jam, pcanut butter, condiment

8. Others: Fine Chemicals, new chemicals, polymer materials, Kaolin, low, medium and high viscosity materials (Liquid-Liquid, Liquid-Solid)..…

Our Advantages

Why Choose Us

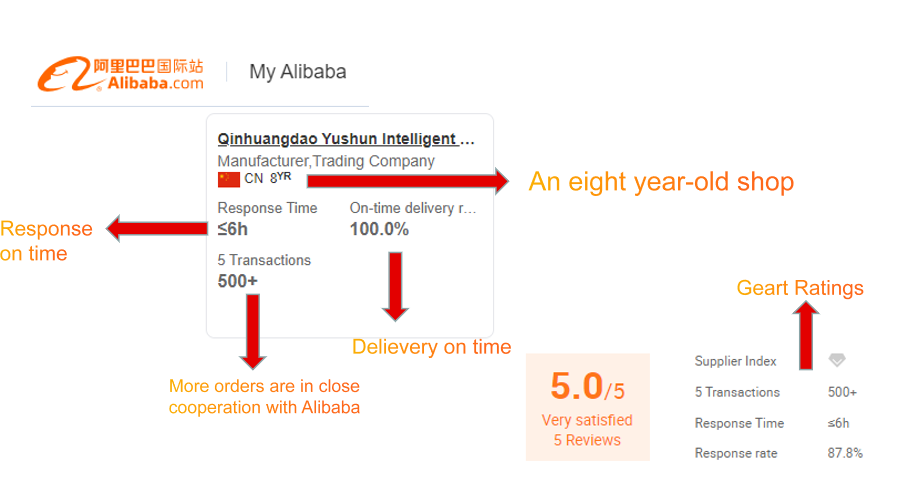

Yushun Intelligent Technology Co., Ltd

Qinhuangdao Yushun Intelligent Technology Co., Ltd established in 1995 with

28 million capital registered

,

not a small workshop

.

Our factory has about 25 years experience in Chemical industry.

We have 17 experienced engineers,

who have rich experience in the mixing and grinding field. Our

quality control departments, after-sales and other aspects are guaranteed.

Our machine are serviced for clients from USA, Russia, Italy, India, Asutralia, Egypt, Sri Lanka, Ukraine, Thailand, Braliz, Malaysia, Vietnam and so on. Our stable quality and service has gained the trust by both internal and international and international clients.

Hot Searches